GE Power & Water

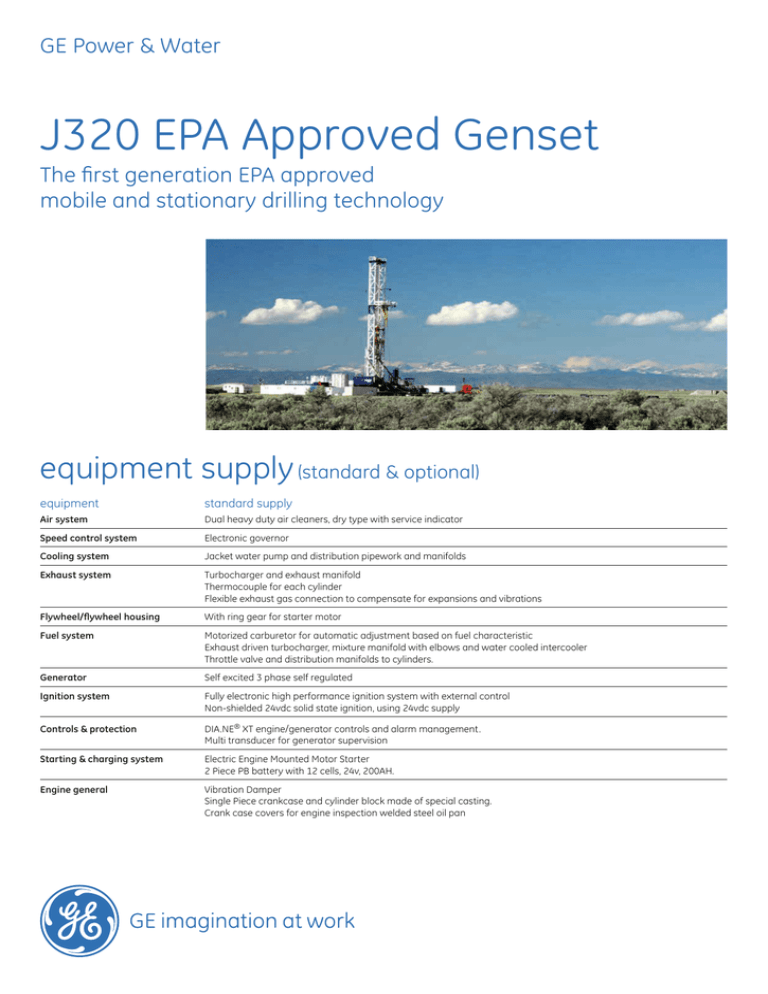

J320 EPA Approved Genset

The first generation EPA approved

mobile and stationary drilling technology

equipment supply (standard & optional)

equipment

standard supply

Air system

Dual heavy duty air cleaners, dry type with service indicator

Speed control system

Electronic governor

Cooling system

Jacket water pump and distribution pipework and manifolds

Exhaust systemTurbocharger and exhaust manifold

Thermocouple for each cylinder

Flexible exhaust gas connection to compensate for expansions and vibrations

Flywheel/flywheel housing

With ring gear for starter motor

Fuel systemMotorized carburetor for automatic adjustment based on fuel characteristic

Exhaust driven turbocharger, mixture manifold with elbows and water cooled intercooler

Throttle valve and distribution manifolds to cylinders.

Generator

Self excited 3 phase self regulated

Ignition systemFully electronic high performance ignition system with external control

Non-shielded 24vdc solid state ignition, using 24vdc supply

Controls & protectionDIA.NE® XT engine/generator controls and alarm management.

Multi transducer for generator supervision

Starting & charging systemElectric Engine Mounted Motor Starter

2 Piece PB battery with 12 cells, 24v, 200AH.

Engine generalVibration Damper

Single Piece crankcase and cylinder block made of special casting.

Crank case covers for engine inspection welded steel oil pan

JGS 320 - technical data*

Imperial

Metric

868 BTU/scft

9,5 kWh/Nm3

Fuel gas LHV

Load

100%

Energy input

MBTU/hr

Gas volume

scfhr *

2

1

Mechanical output

bhp

Electrical output

kW el.

4

75%

50%

2

9.248

7.196

5.143

kW

10.654

8.290

5.925

Nm³/h *

1

1.395

1.046

697

kW

1.007

756

504

kW el. 4

100%

75%

50%

100%

75%

50%

2.711

2.109

1.507

285

222

159

1.040

780

520

1.007

756

504

Heat Balance

Load

heat rejection to Intercooler

1st

100%

75%

50%

stage

MBTU/hr

584

581

34

kW

171

68

10

heat rejection to Intercooler 2nd stage

MBTU/hr

286

185

73

kW

84

56

21

heat rejected to engine oil

MBTU/hr

459

418

377

kW

135

123

111

heat rejection to jacket water

MBTU/hr

1.184

1.180

1.018

kW

347

346

298

~ Surface heat

MBTU/hr 7

216

218

226

kW 7

63

64

66

~ Balance heat

MBTU/hr

147

118

86

kW

43

34

25

100%

75%

50%

BTU/bhp.hr 2 6629

6880

7379

Heat Rate & Efficiency

Load

Fuel Consumption / Heat Rate

Lube oil consumption

gal/hr

Electrical efficiency

%

3

100%

75%

50%

kWh/kWh 2

2,61

2,7

2,9

3

0,31

0,23

0,16

37,20

35,80

33,40

100%

75%

50%

496

504

514

0,1

0,07

0,05

kg/h

37,20

35,80

33,40

%

100%

75%

50%

924

940

957

Load

Exhaust gas temperature at full load

°F 8

°C 8

Exhaust gas mass flow rate, wet

lbs/hr

12.947

9.793

6.805

kg/h

5.872

4.444

3.086

Exhaust gas mass flow rate, dry

lbs/hr

11.981

9.042

6.268

kg/h

5.434

4.103

2.843

100%

75%

50%

100%

75%

50%

12.517

9.459

6.566

5.677

4.292

2.978

Air Intake System

Load

Combustion air mass flow rate

lbs/hr

kg/h

Intercooler Water Temp

122 °F

50 °C

NOx g/bhp-hr (mg/m3 5%O2)

0.6 9

250

CO g/bhp-hr (mg/m3 5%O2)

2.5 9

1000

GEA-17954A

Exhaust System

Design

Number of cylinders

Configuration - crank angle

Bore (in/mm)

Stroke (in/mm)

Displacement (cu.in/l)

Overall dimensions

20

70°

5.31/135

6.69/170

2970/48.67

Capacity for liquids (engine only)

Cooling System (US gal/l)

Lube Oil System - refill (US gal/l)

Engine shipping weight - dry (lb/pkg)

1At nominal speed and standard reference conditions ICFN according to

DIN‑ISO 3046 and DIN 6271, respectively

2 According to DIN‑ISO 3046 and DIN 6271, respectively, with a tolerance of + 5 %

3Average value between oil change intervals according to maintenance schedule,

without oil change amount

4 At p. f. = 1.0 according to VDE 0530 REM / IEC 34.1 with relative tolerances

53/200

90/342

11023/5000

Length (in/mm)

Width (in/mm)

Height (in/mm)

Weight empty (lbs/kgs)

230/5700

70/1700

90/2300

24,270/11,100

GE Power & Water

Jenbacher gas engines Austria (Headquarters)

Achenseestrasse 1-3 6200 Jenbach

T +43 5244 600-2918 F +43 5244 600-584

jenbacher.trainingcenter@ge.com

www.gejenbacher.com

5 Total output with a tolerance of +/‑ 8 %

7 Only valid for engine and generator; module and peripheral equipment not considered

8 Exhaust temperature with a tolerance of +/- 5 %

9 NOx: EPA Method 7E; CO: EPA Method 10

* Special Package Design for 7500 ft altitude and maximum 93°F air intake temperature included.

* Technical data will vary based on changes in altitude and air intake temperature.

GE Power & Water Jenbacher gas engines Austria (Headquarters) 6200 Jenbach T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

© 2013 GE Jenbacher GmbH & Co OG. All rights reserved.

Emissions