Flexible Control Cable Catalog

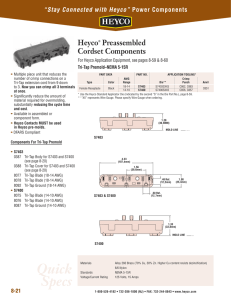

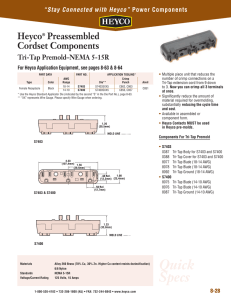

advertisement