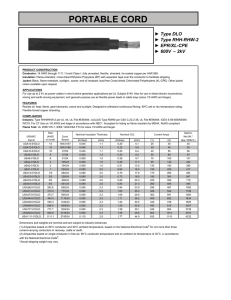

Tricab flexible Industrial Cables

advertisement