PDF - Electric Motion Company

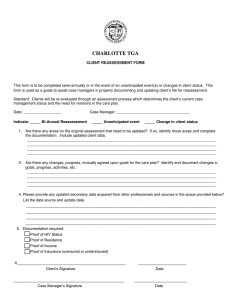

advertisement