E

C

N V I R O N M E N T A L

Liebert

O N T R O L

®

Microprocessor

Control

Energy

Efficient

H IGHEST P RECISION AND

G REATEST E NERGY E FFICIENCY

I N A T RUE F OUR -S TEP D ESIGN

Humidity

Control

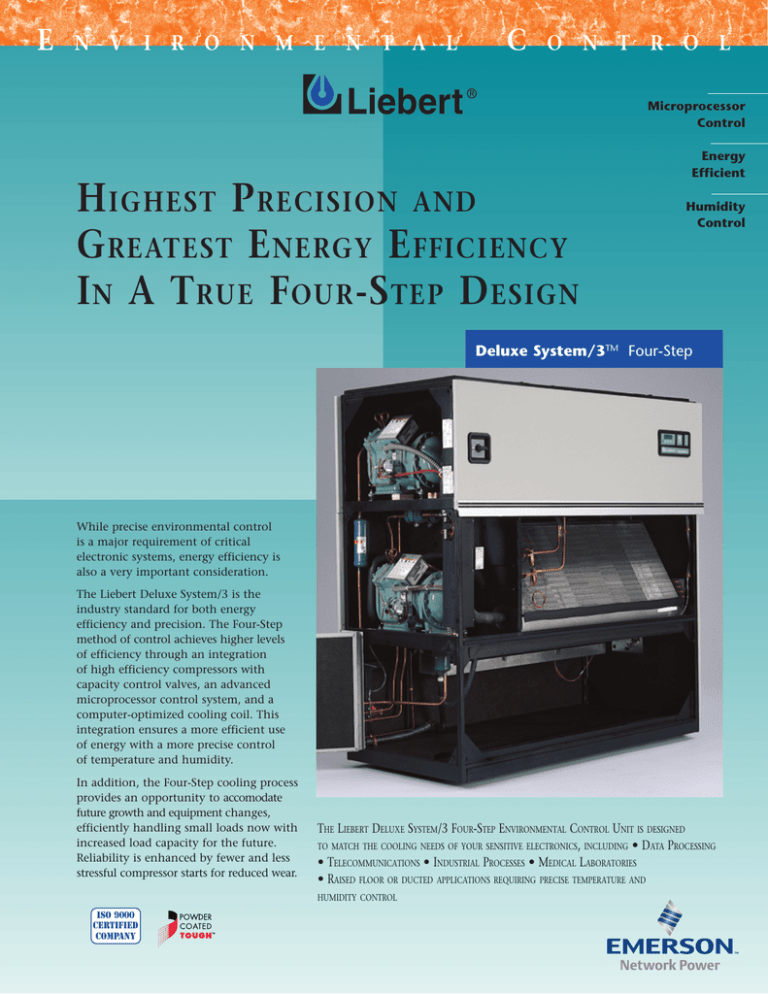

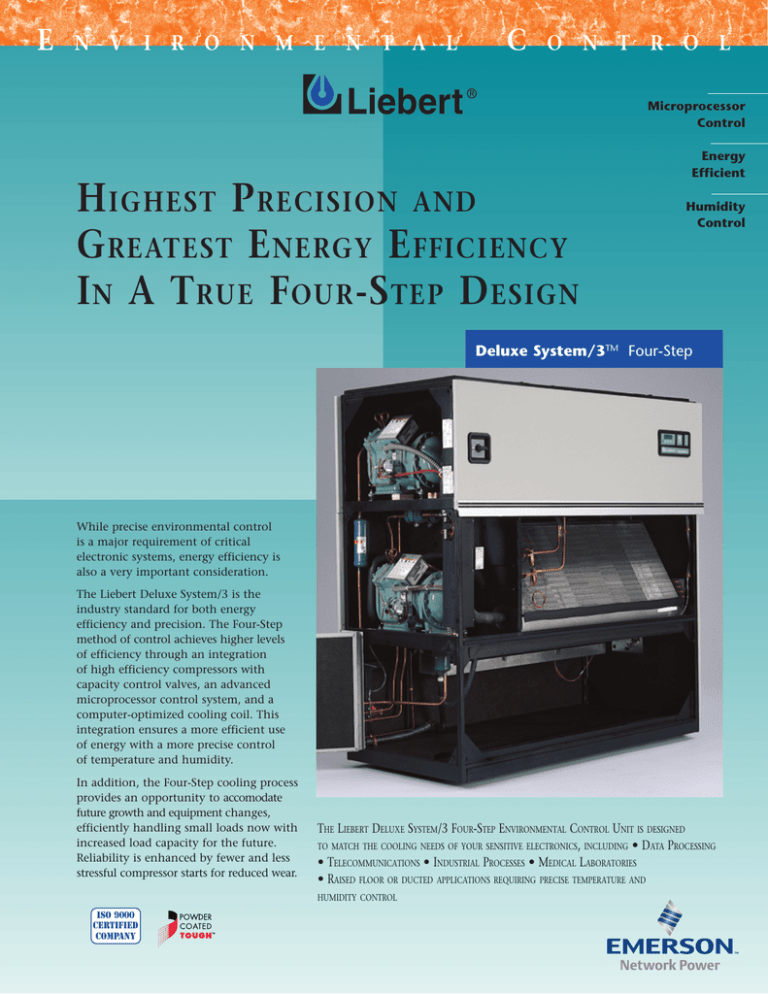

Deluxe System/3TM Four-Step

While precise environmental control

is a major requirement of critical

electronic systems, energy efficiency is

also a very important consideration.

The Liebert Deluxe System/3 is the

industry standard for both energy

efficiency and precision. The Four-Step

method of control achieves higher levels

of efficiency through an integration

of high efficiency compressors with

capacity control valves, an advanced

microprocessor control system, and a

computer-optimized cooling coil. This

integration ensures a more efficient use

of energy with a more precise control

of temperature and humidity.

In addition, the Four-Step cooling process

provides an opportunity to accomodate

future growth and equipment changes,

efficiently handling small loads now with

increased load capacity for the future.

Reliability is enhanced by fewer and less

stressful compressor starts for reduced wear.

THE LIEBERT DELUXE SYSTEM/3 FOUR-STEP ENVIRONMENTAL CONTROL UNIT IS DESIGNED

TO MATCH THE COOLING NEEDS OF YOUR SENSITIVE ELECTRONICS, INCLUDING • DATA PROCESSING

• TELECOMMUNICATIONS • INDUSTRIAL PROCESSES • MEDICAL LABORATORIES

• RAISED FLOOR OR DUCTED APPLICATIONS REQUIRING PRECISE TEMPERATURE AND

HUMIDITY CONTROL

ISO 9000

CERTIFIED

COMPANY

Environmental

Control

T HE F OUR -S TEP S YSTEM ...

..........

The Liebert Four-Step System is a

standard in environmental control

for sensitive electronics.

Liebert’s no-compromise approach

increases energy efficiency while

maintaining the reliability and

precision of the system. These

enhancements increase the

performance level of the system

and more closely track the cooling

load of your critical space.

.......

.......

HOW THE FOUR-STEP SYSTEM WORKS

THE FOUR-STEP SYSTEM USES

FOUR PRIMARY COMPONENTS

The Liebert Deluxe System/3 Four-Step system

achieves four steps of control through the use of two

compressors. Each compressor is equipped with an

additional capacity control valve for modulation. During

steps one and two, the compressors are energized in

the capacity controlled mode. While in step one,

cooling reaches a level of 38%, using only 25% of the

compressor’s energy input. Step two results in 76%

cooling, using only 50% of the energy. Steps three and

four then increase the first and second compressors to

full capacity, only when needed.

• High Energy Compressors. Liebert uses highefficiency semi-hermetic compressors, the standard in

the industry (average compressor EER = 11.69). These

highly reliable and energy efficient compressors are

an integral part of the Four-Step system.

• A-Frame Evaporator Coil. The Liebert

A-Frame coil, designed and manufactured by Liebert,

provides maximum performance and improved

dehumidification capabilities whether the

compressors are operating at full or reduced capacity.

• Capacity Control Valve. Each high efficiency

compressor is equipped with a capacity control valve

(CCV). The valves function to regulate compressor

capacity by isolating cylinders and providing

additional steps of control.

• Microprocessor Controls. The Deluxe System/3

Four-Step can be programmed to meet the specific

and precise needs of any critical space. The result is a

level of control previously unavailable in environmental control systems. In addition to local monitoring,

control, and alarm indicators, the microprocessor

communicates with the Liebert SiteScan monitoring

system as part of a total protection network. The

Advanced Microprocessor Control and Advanced

Microprocessor Control with Graphics are user-friendly

with menu-driven monitors/control panels.

2

P ERFORMANCE

S ECOND T O N ONE

ENERGY SAVINGS

100%

100%

88%

75%

76%

50%

.......

38%

ENERGY SAVINGS

The chart at the right shows the cooling performance of

the Four-Step system at each step of control. The area

between the dotted lines represents the heat load

typical electronic equipment produces. It is within this

area that Four-Step performance is optimal.

For example, in Step Two, for a 15-ton unit (both

compressors operating with the capacity control valve

activated), the Four-Step system produces 76% of the

total capacity using only 50% of the energy. Full

capacity is available when needed. But, during those

times when it is not, the Four-Step system provides a

major operating cost advantage.

To give you a more individualized analysis of your

operations and environmental needs, Liebert can provide a comprehensive, computerized energy analysis to

show you just how much you can save using the Liebert

Four-Step system.

.......

PRECISION

Because the Four-Step system modulates capacity in

four small steps, room temperature and humidity

control are maximized. The capacity control valves

enable the system to more closely track room load

changes for greater precision and less

humidity fluctuation.

25%

Step Four

Step Three

■ Capacity

■ Energy

Step Two

Step One

■ Energy Savings

.......

RELIABILITY

All Liebert systems are designed and built with the

highest quality components and engineering expertise.

This reputation for reliability is enhanced in the Liebert

Deluxe System/3 Four-Step in many ways: First,

compressors are always started with the control valve

activated, resulting in less wear and lower inrush power;

secondly, the greater control means less cycling and

extended service life. The semi-hermetic compressors

are highly efficient, and the draw-through air pattern

combined with a large face area evaporator coil results

in efficient air movement. Additional features that

increase value and reliability include stainless steel

fin-tube reheat and a multiple blower fan section. The

microprocessor control allows a sequenced start of all

components and reduced start of compressors.

Additional support is provided after hours, seven days

a week, by calling Liebert at 800-877-9222 if problems

should occur.

.......

AVAILABILITY

The Four-Step option is available in most

compressorized versions of Deluxe System/3. This

allows the use of this option in applications ranging

from air cooled through GLYCOOL-configurations.

Four-Step applications permit additional savings of

20-40% over standard Liebert systems and greater

savings when compared to comparative models.

3

Liebert

®

Keeping Business in Business

Deluxe System/3®-Four Step Capacity Data—60 Hz

8 Ton

10 Ton

15 Ton

20 Ton

22 Ton

30Ton

Capacity Data BTU/HR (kW) 75°F DB, 62.5°F WB (23.9°C DB, 16.9°C WB) 50% RH

AIR COOLED

Total

DH/VH 114AU

DH/VH 125AU

DH/VH 199AU

DH/VH 245AU

DH/VH 290AU

DH/VH 380AU

114,200 (33.5)

125,500 (36.7)

178,000 (52.2)

227,300 (66.6)

259,300 (76.0)

353,400 (103.5)

312,600 (88.6)

90,200 (26.4)

111,900 (32.8)

163,600 (47.9)

201,200 (59.0)

229,700 (67.3)

WATER COOLED

Sensible

DH/VH 127WU

DH/VH 138WU

DH/VH 219WU

DH/VH 267WU

DH/VH 315WU

DH/VH 412WU

Total

122,300 (35.8)

136,500 (40.0)

197,900 (58.0)

247,700 (72.6)

286,900 (84.1)

384,200 (112.6)

315,000 (92.3)

93,500 (27.4)

166,300 (34.1)

171,500 (50.2)

209,300 (61.3)

240,700 (70.5

GLYCOL COOLED

Sensible

DH/VH 110GU

DH/VH 116GU

DH/VH 192GU

DH/VH 240GU

DH/VH 265GU

DH/VH 363GU

Total

103,900 (30.4)

114,400 (33.5)

172,200 (50.4)

216,100 (63.3)

250,100 (73.2)

341,100 (99.9)

Sensible

86,100 (25.2)

107,500 (31.4)

161,300 (47.2)

196,700 (57.6)

226,100 (66.2)

297,800 (87.3)

GLYCOOL SYSTEMS

DE/VE 110GU

DE/VE 116GU

DE/VE 192GU

DE/VE 240GU

—

DE/VE 363GU

Total

103,900 (30.4)

114,400 (33.5)

172,200 (50.4)

216,100 (63.3)

—

338,300 (96.8)

Sensible

86,100 (25.2)

107,500 (31.4)

161,300 (47.2)

196,700 (57.6)

—

288,400 (84.5)

Deluxe System/3 -Four Step Capacity Data—50 Hz

®

Capacity Data BTU/HR (kW) 75°F DB, 62.5°F WB (23.9°C DB, 16.9°C WB) 50% RH

AIR COOLED

Total

DH/VH 115AU

DH/VH 130AU

DH/VH 199AU

DH/VH 245AU

DH/VH 290AU

DH/VH 380AU

29.8 (101,600)

37.0 (126,300)

47.0 (160,200)

59.7 (203,800)

68.1 (232,200)

91.2 (311,300)

83.9 (286,100)

24.9 (85,100)

32.9 (112,200)

47.0 (160,200)

59.7 (203,800)

68.1 (232,200)

WATER COOLED

Sensible

DH/VH 128WU

DH/VH 143WU

DH/VH 219WU

DH/VH 267WU

DH/VH 315WU

DH/VH 412WU

Total

31.7 (108,200)

40.7 (138,900)

50.7 (172,900)

63.7 (217,500)

74.0 (252,500)

99.1 (338,200)

87.0 (296,700)

25.7 (87,800)

34.4 (117,300)

47.4 (161,600)

57.8 (197,300)

66.5 (227,000)

GLYCOL COOLED

Sensible

DH/VH 111GU

DH/VH 121GU

DH/VH 192GU

DH/VH 240GU

DH/VH 265GU

DH/VH 363GU

Total

27.8 (94,800)

34.4 (117,400)

45.7 (155,800)

57.1 (194,900)

66.1 (225,500)

88.3 (301,100)

Sensible

24.2 (82,500)

31.9 (108,700)

45.7 (155,800)

57.1 (194,900)

66.1 (225,500)

82.7 (282,100)

GLYCOOL SYSTEMS

DE/VE 111GU

DE/VE 121GU

DE/VE 192GU

DE/VE 240GU

—

DE/VE 363GU

Total

27.8 (94,800)

34.4 (117,400)

45.7 (155,800)

57.1 (194,900)

—

88.3 (301,100)

Sensible

24.2 (82,500)

31.9 (108,700)

45.7 (155,800)

57.1 (194,900)

—

82.7 (282,100)

..........

1050 DEARBORN DRIVE

P.O. BOX 29186

COLUMBUS, OHIO 43229

800.877.9222 PHONE (U.S. & CANADA ONLY)

614.888.0246 PHONE (OUTSIDE U.S.)

614.841.6022 FAX

upstech@liebert.com EMAIL

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco

Italy

39 049 9719 111 Phone

39 049 5841 257 FAX

23/F, Allied Kajima Bldg.

138 Gloucester Road

Wanchai

Hong Kong

852 2 572 2201 Phone

852 2 831 0114 FAX

..........

LIEBERT WEB SITE

http://www.liebert.com

EQUIPMENT SELECTION GUIDE

30

22

UNIT SIZE (TONS)

LIEBERT CORPORATION

DH/DE = Downflow System, VH/VE = Upflow System

20

15

10

8

40

80

120

160

HEAT LOAD (BTU

200

X

240

280

320

1,000)

Operating Range

Peak Efficiency

NOTES:

1) Equipment Selection Guide is based on 60 Hz air-cooled capacities at 75°F/50% RH.

Other models or conditions will vary slightly.

2) For a comprehensive analysis of size or model efficiencies to aid in correct equipment selection,

contact your local Liebert representative or call 800.877.9222.

While every precaution has been taken to ensure accuracy and completeness in this literature, Liebert Corporation assumes no

responsibility, and disclaims all liability for damages resulting from use of this information or for any errors or omissions.

© 1998 Liebert Corporation. All rights reserved throughout the world. Specifications subject to change without notice.

All names referred to are trademarks or registered trademarks of their respective owners.

® Liebert and the Liebert logo are registered trademarks of the Liebert Corporation.

® Keeping Business in Business is a registered trademark of the Liebert Corporation.

SL-18030 (R 6/01)

Printed in USA