Certified - Electrol Power Whips

advertisement

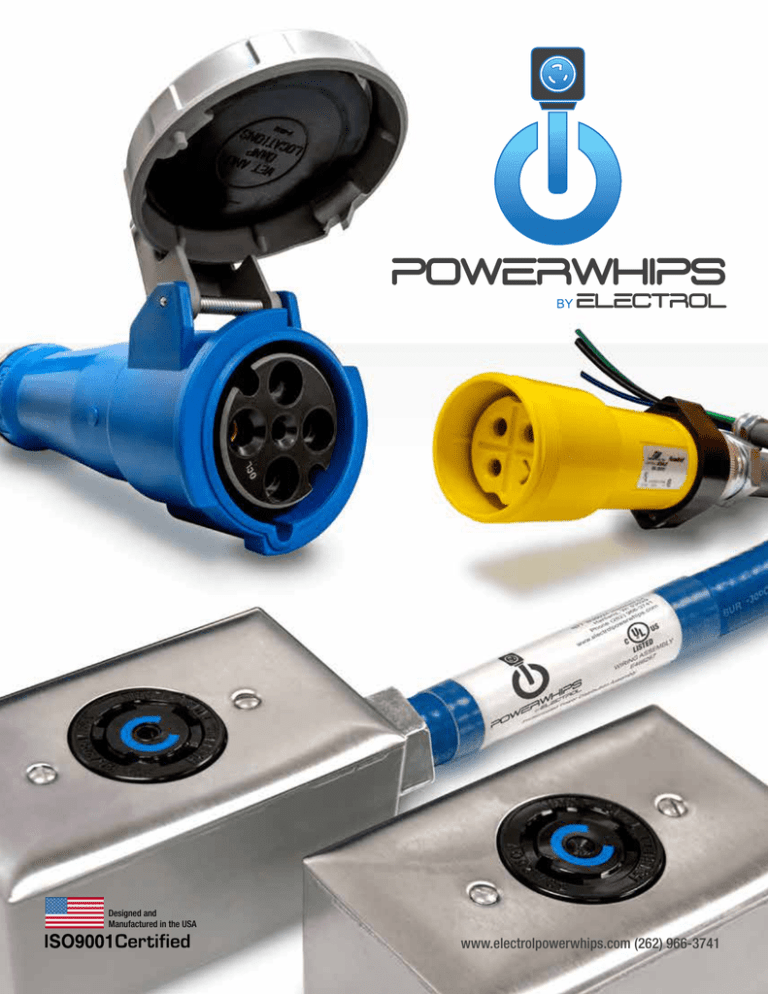

Designed and Manufactured in the USA Certified www.electrolpowerwhips.com (262) 966-3741 Data Center Power Distribution Cable Assemblies Electrol understands that there is no room for product failure in mission critical data centers. The higher levels of quality components, precision manufacturing and testing - along with the special care and attention to detail that we build into our PowerWhip products, assures you that each whip will meet or exceed the high levels of reliability and performance standards they have been designed for: • 40,000 Sq. Ft. Manufacturing Facility • Located in Hartland, Wisconsin • Established in 1961 • Core competency - Power Distribution Cables • ISO 9001:2008 - Underwriters Laboratories • UL Certified PowerWhips • Lean and Six Sigma Certifications 2 www.electrolpowerwhips.com (262) 966-3741 Features • Online PowerWhip configurator • UL Listed • 100% inspected and pre-tested before shipment • Electrol only uses the highest quality UL Listed components • Standard mounting hardware is available upon request • Liquid tight conduit is available in eleven colors • Typically ships in 1-3 days • Inventory programs available • Competitively priced • Alternative components available • Custom tail lengths to any specification Benefits • Eleven liquid tight colors help distinguish primary power from redundant power • Factory testing ensures reliability and performance • PowerWhips and whip tails are cut to the exact length specification • Minimizes workload at the job site www.electrolpowerwhips.com (262) 966-3741 3 NEMA Locking: • Locking connectors provide a more reliable connection • Helps prevent disconnects typically caused by vibration or incidental impact • Available in a variety of standardized configurations • Designed so that different voltages and currents cannot be accidentally intermated Receptacle Data 4 Powerwhip Part Number Isolated Ground E-L5-15RLLL-CDCCWT E-IG-L5-15RLLL-CDCCWT E-L6-15RLLL-CDCCWT E-IG-L6-15RLLL-CDCCWT E-L7-15RLLL-CDCCWT E-L5-20RLLL-CDCCWT E-IG-L5-20RLLL-CDCCWT E-L6-20RLLL-CDCCWT E-IG-L6-20RLLL-CDCCWT E-L14-20RLLL-CDCCWT E-IG-L14-20RLLL-CDCCWT E-L15-20RLLL-CDCCWT E-IG-L15-20RLLL-CDCCWT E-L21-20RLLL-CDCCWT E-IG-L21-20RLLL-CDCCWT E-L5-30RLLL-CDCCWT E-IG-L5-30RLLL-CDCCWT E-L6-30RLLL-CDCCWT E-IG-L6-30RLLL-CDCCWT E-L14-30RLLL-CDCCWT E-IG-L14-30RLLL-CDCCWT E-L15-30RLLL-CDCCWT E-IG-L15-30RLLL-CDCCWT E-L21-30RLLL-CDCCWT E-IG-L21-30RLLL-CDCCWT N Y N Y N N Y N Y N Y N Y N Y N Y N Y N Y N Y N Y Connector/ Receptacle Type L5-15R IG-L5-15R L6-15R IG-L6-15R L7-15R L5-20R IG-L5-20R L6-20R IG-L6-20R L14-20R IG-L14-20R L15-20R IG-L15-20R L21-20R IG-L21-20R L5-30R IG-L5-30R L6-30R IG-L6-30R L14-30R IG-L14-30R L15-30R IG-L15-30R L21-30R IG-L21-30R www.electrolpowerwhips.com (262) 966-3741 Conduit Diameter Amperage Voltage Phase Min/Max Sizes 15 15 15 15 15 20 20 20 20 20 20 20 20 20 20 30 30 30 30 30 30 30 30 30 30 125 125 250 250 277 125 125 250 250 125/250 125/250 250 250 120/208 120/208 125 125 250 250 125/250 125/250 250 250 120/208 120/208 1 1 1 1 1 1 1 1 1 1 1 3 3 3Y 3Y 1 1 1 1 1 1 3 3 3Y 3Y 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" CD in Part Number = Diameter 11 = 0.50” 12 = 0.75” 13 = 1.00” 14 = 1.25” 15 = 1.50” 16 = 2.00” Wire Data-Circuit Conductor Wire Data-Ground Conductor Quantity AWG Spec Color AWG Spec Color 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 3P-4W 3P-4W 3P-4W 3P-4W 4P-5W 4P-5W 2P-3W 2P-3W 2P-3W 2P-3W 3P-4W 3P-4W 3P-4W 3P-4W 4P-5W 4P-5W THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN WT / BK WT / BK RD / BK RD / BK RD / BK WT / BK WT / BK RD / BK RD / BK RD / BK / BL RD / BK / BL RD / BK / BL RD / BK / BL RD / BK / BL / WT RD / BK / BL / WT WT / BK WT / BK RD / BK RD / BK RD / BK / BL RD / BK / BL RD / BK / BL RD / BK / BL RD / BK / BL / WT RD / BK / BL / WT 12 12 12 12 12 12 12 12 12 12 12 12 12 12 12 10 10 10 10 10 10 10 10 10 10 THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN 12 12 12 12 12 12 12 12 12 12 12 12 12 12 12 10 10 10 10 10 10 10 10 10 10 Russell Stoll: • Toughest construction in thermoplastic safety in UL 94-VO flame-rated DuraV material • DurOring sealed pins, sleeves and interiors are watertight even unmated • 30A and 50A unique circuit interlock line in DuraV are the best choices in all standard voltage polarization options through 600VAC (interlock to 480VAC) • Angle type plugs-the original 60A main power computer system connector-are available in UL94-VO specialty material (Aluminum Connectors) • Other lines such as MaxGard should be used for change out when possible Receptacle Data Powerwhip Part Number Connector/Receptacle Type E-9C23U3-LLL-CDCCWT 3913U2 (IBM A-U2) DuraGard E-9C24U2-LLL-CDCCWT 3914 (IBM B) DuraGard E-9C23U2-LLL-CDCCWT 3913 (IBM A) DuraGard E-9C23U1-LLL-CDCCWT 3913U1 (IBM A-U1) DuraGard E-9C23U0-LLL-CDCCWT 9C23U0 E-9C23U2-LLL-CDCCWT 9C23U2 E-DF3207FR0E0-LLL-CDCCWT 3933 (IBM C) MaxGard E-9C33U2-LLL-CDCCWT 3933 (IBM C) DuraGard E-9C33U0-LLL-CDCCWT 9C33U0 E-9C33U2-LLL-CDCCWT 9C33U2 E-DF3407FR0E0-LLL-CDCCWT 3934 (IBM D) MaxGard E- 9C34U2-LLL-CDCCWT 3934 (IBM D) DuraGard E- 9C34U0-LLL-CDCCWT 9C34U0 E- 9C34U2-LLL-CDCCWT 9C34U2 E- 9C53U0-LLL-CDCCWT 9C53U0 E-9C53U2-LLL-CDCCWT 9C53U2 E-9C54U0-LLL-CDCCWT 9C54U0 E-9C54U2-LLL-CDCCWT 9C54U2 E-9C63U2-LLL-CDCCWT 9C63U2 E-DF6414FR0E0-LLL-CDCCWT 7428-78 (IBM E) MaxGard E-DF1414FR0E0-LLL-CDCCWT 7324-78 (IBM) MaxGard E-DF6414FR0E0-LLL-CDCCWT JCS1034H (IBM F) MaxGard Conduit Diameter Amperage Voltage Phase Min/Max Sizes 15 15 20 20 20 20 30 30 30 30 30 30 30 30 50 50 50 50 60 60 60 100 277 250 250 125 600 250 250 250 600 250 250 250 600 250 600 250 600 250 250 250 250 250 1 3 1 1 1 1 1 1 1 1 3 3 3 3 1 1 3 3 1 3 3 3 0.50" / 0.75" 0.50" / 0.75" 0.50" / 0.75" 0.50" / 0.75" 0.50" / 0.75" 0.50" / 0.75" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.75" / 1.00" 0.75" / 1.00" 0.75" / 1.00" 1.00" / 1.25" / 1.50" 1.00" / 1.25" / 1.50" 1.25" / 1.50" Conduit Color Codes (BK) Black (BL) Blue (BN) Brown (GN) Green (GY) Gray (OR) Orange (PK) Pink (PL) Purple (RD) Red (WT) White (YL) Yellow CC in Part Number Wire Data-Circuit Conductor Quantity AWG 2P-3W 3P-4W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 2P-3W 3P-4W 3P-4W 3P-4W 3P-4W 2P-3W 2P-3W 3P-4W 3P-4W 2P-3W 3P-4W 3P-4W 3P-4W 12 12 12 12 12 12 10 10 10 10 10 10 10 10 6 6 6 6 4 4 4 1 Wire Data-Ground Conductor Spec Color AWG Spec Color THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN RD / BK RD / BK / BL RD / BK WT / BK RD / BK RD / BK RD / BK RD / BK RD / BK RD / BK RD / BK / BL RD / BK / BL RD / BK / BL RD / BK / BL RD / BK RD / BK RD / BK / BL RD / BK / BL RD / BK RD / BK / BL RD / BK / BL RD / BK / BL 12 12 12 12 12 12 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 8 THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN GN LLL in Part Number = Length in Feet 001 = 1 Foot 002 = 2 Feet 003 = 3 Feet www.electrolpowerwhips.com (262) 966-3741 5 IEC Pin and Sleeve: • IEC 60309 (formerly IEC 309) is an international standard for plugs, socket-outlets and couplers for industrial purposes • Includes a range of plugs and sockets of different sizes with differing numbers of pins, depending on the current supplied and number of phases accommodated • Fittings include (IP44) weather-proofing, a preferred solution for open-air conditions • Prevents potential users from connecting domestic appliances to the sockets • Used for heavy current demands and when three phases are needed Receptacle Data Conduit Diameter Wire Data-Circuit Conductor Powerwhip Part Number Connector/Receptacle Type Amperage Voltage Phase Min/Max Sizes E-320C6WLLL-CDCCWT E-420C9WLLL-CDCCWT E-330C6WLLL-CDCCWT E-430C7WLLL-CDCCWT E-430C9WLLL-CDCCWT E-530R7WLLL-CDCCWT E-360C6WLLL-CDCCWT E-460C9WLLL-CDCCWT E-460R9WLLL-CDCCWT E-560C9WLLL-CDCCWT E-4100C9WLLL-CDCCWT E-5100C9WLLL-CDCCWT 320C6W 420C9W 330C6W 430C7W 430C9W 530R7W 360C6W 460C9W 460R9W 560C9W 4100C9W 5100C9W 20 20 30 30 30 30 60 60 60 60 100 100 250 250 250 480 250 277 250 250 250 120/208 250 120/208 1 3 1 3 3 3Y 1 3 3 3Y 3 3Y 0.50" / 0.75" 0.50" / 0.75" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.50" / 0.75" / 1.00" 0.75" / 1.00" / 1.25" 1.00" / 1.25" 1.00" / 1.25" / 1.50" 1.25" 1.25" / 1.50" 1.50" Quantity AWG 2P-3W 3P-4W 2P-3W 3P-4W 3P-4W 4P-5W 2P-3W 3P-4W 3P-4W 4P-5W 3P-4W 4P-5W 12 12 10 10 10 10 4 4 4 4 1 1 Wire Data-Ground Conductor Spec Color AWG Spec Color THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN RD / BK RD / BK / BL RD / BK RD / BK / BL RD / BK / BL RD / BK / BL / WT RD / BK RD / BK / BL RD / BK / BL RD / BK / BL / WT RD / BK / BL RD / BK / BL / WT 12 12 10 10 10 10 10 10 10 10 8 8 THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN THHN GN GN GN GN GN GN GN GN GN GN GN GN Labeling: • PowerWhips are labeled at each end and tail to help identify critical power pathways • The labels include UL certification, PDU/RPP identification, and circuit number • Custom labeling is available Customer Provided Receptacle Schedule Electrol Part Number E-HBL460R9W063-13BL12 6 Row Cabinet RPP Receptacle Type BW BV42 HBL460R9W BW12 www.electrolpowerwhips.com (262) 966-3741 Job Number 330187 “LLL” CD Conduit Length Diameter (Cable) Feet Inches 63 1.00 CC Conduit Color BLUE WT Length (Whip Tail) FT 12 Order Quantity 1 Exemplary In House Testing Service: Our extensive testing and inspection processes deliver power distribution cables that feature unmatched reliability and performance to meet the industry’s most demanding requirements: • All PowerWhips are tested in our factory ensuring performance • Testing is completed per UL requirements • Testing ensures continuity, ground integrity, and no insulation leakage • Phase rotation and Hi-Pot testing are also standard • Test results ship with each order Why build your own whips when we can ship PowerWhips to you faster?... • Ships faster than building your own – minimizes downtime • Online PowerWhip configurator • UL listed cables are 100% pretested and inspected • Ready for installation upon arrival • Choice of highest quality components • Custom packaging available • Conform to UL #478 , NEC Article 350.30A, NEC Article 645.50E • Standard or custom whips • ISO 9001:2008 - Underwriters Laboratories • Permanent labeling for cabling on each side to facilitate identification of critical power pathways www.electrolpowerwhips.com (262) 966-3741 7 About Us: For over five decades, Electrol has met the cabling and power needs for some of the world’s largest companies who have trusted us to deliver quality products with zero failure expectation. Established in 1961, Electrol initially started out as a large panel builder for medical equipment. The company expanded into cable and harness assemblies throughout the 1960’s, during this time they continued to expand their capabilities and customer base through strategic growth. Electrol moved to its current 40,000 sq. ft. facility in Hartland, Wisconsin in 1995. Fortune 100 Companies have assigned us the mission critical task of supplying connectivity, power and cabling products to the IT, Medical, Government/Military and Communication markets. Our strategy is simple; we create and deliver value. As an ISO9001 company, Electrol continues to provide high-quality, practical, cable assemblies for today’s most demanding applications. LIMITED WARRANTY: Electrol sells this product with the understanding that the user will perform all necessary tests to determine the suitability of this product for the end user’s intended application. Electrol warrants that this product will be free from defects in material and workmanship for a period of two (2) years following the date of purchase. Upon prompt notification of any warranted defect, Electrol will, at its option, repair or replace the defective product or refund the purchase price. Proof of purchase is required. Misuse or unauthorized modification of this product voids all warranties. LIMITATIONS AND EXCLUSIONS: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY DISCLAIMED. LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST OF REPAIR OR REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL ELECTROL BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. PowerWhips by Electrol N77 W30924 Hartman Court Hartland, WI 53029 www.electrolpowerwhips.com (262) 966-3741