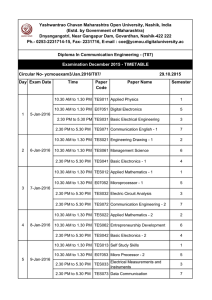

ATP bioluminescence to establish a test procedure for

advertisement