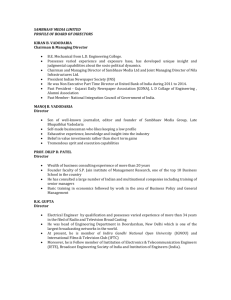

akshar-travels-indus..

advertisement

SPECIAL GUJARAT INDUSTRIAL TOUR - 11 NIGHTS / 12 DAYS ( Ahmedabad – Sanand – Rajkot – Jamnagar – Dwarka – Porbandar –Somnath – Piparav – Bhavnagar – Ahmedabad – Gandhinagar – Ahmedabad – Baroda – Surat ) DAY : 01 AHMEDABAD – SANAND – RAJKOT Today Morning We Will Proceed To Sanand For Visit TATA NANO FACTORY. Tata Motors’ Plant For The Tata Nano At Sanand, In Ahmedabad District Of Gujarat, Marks The Culmination Of The Company’s Goal Of Making The Tata Nano Available To Hundreds Of Thousands Of Families, Desirous Of The Car A Safe, Affordable And Environmental Friendly Mode Of Transport. The Capacity Of The Plant, To Begin With, Will Be 250,000 Cars Per Year To Be Achieved In Phases, And With Some Balancing Is Expandable Up To 350,000 Cars Per Year.Provision For Further Capacity Expansion Has Also Been Incorporated In This Location. Built In A Record Time Of 14 Months Starting November 2008, The Integrated Facility Comprises Tata Motors’ Own Plant, Spread Over 725 Acres, And An Adjacent Vendor Park, And Spread Over 375 Acres, To House Key Component Manufacturers For The Tata Nano.In Line With Latest World-Class Manufacturing Practices, The Tata Nano Plant Has Been Equipped With State-Of-The-Art Equipment. They Include Sophisticated Robotics And High Speed Production Lines. Conscious Of The Critical Need Of Environment Protection, The Plant Has Energy-Efficient Motors, Variable Frequency Drives, And Systems To Measure And Monitor Carbon Levels. These Are Supplemented With Extensive Tree Plantation, Sustainable Water Sourcing Through Water Harvesting And Ground Water Recharging And Harnessing Solar Energy For Illumination .Overnight Stay At Rajkot. (B, L, D). DAYS : 02 RAJKOTMORBI - JAMNAGAR Today After Breakfast Visit AJANTA CLOCK FACTORY Ajanta Limited, Better Known By The Brand Name ORPAT, Situated In Morbi (Gujarat), Has A Built-Up Area Of 15,00,000 Sq. Ft. The Company Currently Provides Employment To More Than 4000 Employees (90% Of Which are Female Employees).This Enormous Volume Of Infrastructure Helped The Company In Achieving Big Goals Since Years. And Now The Company Stands On A Strong Ground And Has The Credit Of World’s Largest Clock Manufacturer As Well As The Only Company In India That Manufacturer Calculators And Educational Toys And The Market Leader In The Telephones Manufacturing. After We Visit CERAMIC INDUSTRY Morbi To An Extent That It Is Recognized Worldwide As Ceramic Hub Of India.The Initiation Phase Of Ceramics In India Is Very Interesting. It Started In 1913 With An Idea Clicked To Mr. Shorab Dalal As He Saw A Traditional Smoking Pipe At Thangadh Railway Station. The Idea Inspired Him To Venture Into Ceramics. He Was The Pioneer Who Planted Roots Of Gujarat Ceramics With Roofing Tiles Industry In Thangadh Without Having Any Predefined Path And A Predictable Destination. It Was Only His Obsession Which Led Him To Experimentation & Exploration By Establishing Unlimited Scope In Ceramics. Continuing The Journey Ahead, In 1934, Late Sri Parshuram Balwant Gunpule Took Over That Roof Tiles Factory With A Great Vision And Desire To Succeed. During The Decade 1930 To 1940, For Getting The Required Expertise & Know-How, He Invited Ceramic Technicians From Other States. With This, He Ventured Into Business Of Potteries With Inception Of New Pottery Units In Jabalpur And Nagpur. Stay Overnight At Jamnagar. (B, L, D). DAYS - 03 JAMNAGAR - DWARKA After Breakfast Proceed To Visit RELIANCE PETROLEUM INDUSTRY Jamnagar Manufacturing Division Is Located Near Jamnagar, Gujarat.It Comprises Of A Petroleum Refinery And Associated Petrochemical Plants. The Refinery Is Equipped To Refine Various Types Of Crude Oil (Sour Crude, Sweet Crude Or A Mixture Of Both) And Manufactures Various Grades Of Fuel From Motor Gasoline To Aviation Turbine Fuel (ATF). The Petrochemicals Plants Produces Plastics And Fibre Intermediates.The Jamnagar Manufacturing Division Has A 33 - Million Tonnes Per Annum Refinery That Is Fully Integrated With Downstream Petrochemicals Units Which Manufacture Naphtha-Based Aromatics As Well As PropyleneBased Polymers. Jamnagar Has More Than 50 Process Units, Which Together Process The Basic Feedstock, Crude Oil, To Obtain Various Finished Products Deploying The Following Major Refining Processes: The Refinery Has Successfully Processed More Than 20 Types Of Crude Oils, Including Difficult Crude Oils Within A Few Months Of Its Start-Up, Thus Reflecting Superior Quality Of Assets And Capabilities. Exports Have Commenced To 26 Countries, Including To The US And Europe. Evening We Will Reach At Dwarka, Visit To Dwarkadhish Temple Stay Overnight At Dwarka. (B, L, D) DAYS - 04 DWARKA - OKHA After Breakfast We Proceed To Visit Of TATA SALT FACTORY Mithapur Is Located On The Extreme Tip Of The Lower Jaw Of Gujarat. This Town Is Essentially A Colony That Is Supported By Tata Chemicals Ltd., One Of The Flagship Companies Of The Tata Group.The Company Produces Soda Ash And Tata Salt As Its Core Products. The Company Also Added A Cement Plant In The 90s And Uses The Waste Products From Its Soda Ash Plant And The Boilers That Run The Power Plant To Produce Construction Grade Cement. This Town Is Located Between Okha And Dwarka. It Is About 10 Km From Okha And About 20 Km From Dwarka. Mithapur Also Has! Twin Town, Called Surajkaradi. Surajkaradi Is Mostly The Trade Town.Enroute Visit Cement Factory Enroute Visit CEMENT FACTORY-OKHA TCL’s Cement Business Grew Out Of A Sustainability And Environment Activity; The Cement Plant At Mithapur Was Set Up To Consume Solid Waste Generated During The Manufacture Of Soda Ash. The Area Around Mithapur Is Rich In Limestone. Given The Region’s Proximity To The Sea, Salt Is Also Found Here In Abundance. Lime And Salt Are The Main Ingredients In The Production Of Soda Ash. The Manufacturing Process Of Soda Ash Leaves Behind A Large Quantity Of Unutilised Limestone And Calcium Products In The Slurry. In Order To Utilise The By-Products And Unutilised Limestone, TCL Put Up A Modern Cement Plant At Mithapur. Overnight At Dwarka. (B, L, D) DAYS - 05 DWARKA - PORBANDAR-SOMNATH After Breakfast Proceeds To Somnath Via Porbandar Enroute We Visit MAHATMA GANDHI `S NATIVE & HARI-SIDDH TEMPLE. Evening Attent To Sandhya Arti In Somnath And Light & Sound Show Stay Overnight At Somnath. (B, L, D). DAYS - 06 SOMNATH - PIPAVA - BHAVNAGAR After Breakfast Visit PIPAVAV PORT India’s First Port In The Private Sector, Is A Port On The West Coast Of India For Containers, Bulk And Liquid Cargo. Its Lead Promoter Is APM Terminals, One Of The Largest Container Terminal Operators In The World. The Services Include Pilotage/Towage, Cargo Handling And Logistics Support. Port Pipavav Is Located In Saurashtra, Gujarat, At A Distance Of 90 Km South Of Amreli, 15 Km South Of Rajula And 140 Km South West Of Bhavnagar. The Port Handles Both Bulk, Container And Liquid Cargo. Overnight At Bhavnagar. (B, L, D). DAYS - 07 BHAVNAGAR – ALANG – BHAVNAGAR After Breakfast We Visit ALANG Is The Largest Ship Recycling Yard In The World. Approximately 10 Kms. Long Sea Front On The Western Coast Of The Gulf Of Cambay Adjoining To Alang-Sosiya Village Is Developed As Ship Recycling Yard. By Road, It Is About 50 Kms. From Bhavnagar. Nearest Airport And Railway Station Is Bhavnagar. Alang Is Well Connected By Road. Overnight At Bhavnagar. (B, L, D) DAYS - 08 BHAVNAGAR – AHMEDABAD After Breakfast We Proceed To Ahmedabad For Visit ARVIND MILLS The Year 1930 Was When The World Suffered The Great Depression. Companies Across The Globe Began Closing Down. In UK And In India, The Textile Industry In Particular Was In Trouble. At About This Time, Mahatma Gandhi Championed The Swadeshi Movement And At His Call, People From All Across India Began Boycotting Fine And Superfine Fabrics, Which Had So Far Been Imported From England. In The Midst Of This Depression One Family Saw Opportunity. The Lalbhais Reasoned That The Demand For Fine And Superfine Fabrics Still Existed.And Any Indian Company That Met This Demand Would Surely Prosper. The Three Brothers, Kasturbhai, Narottambhai And Chimanbhai, Decided To Set Up A Mill To Produce Superfine Fabric. Next They Looked Around For State-Of-The-Art Machinery That Could Produce Such High Quality Fabric. Their Search Ended In England. The Best Technology Of That Time Was Acquired At A Most Attractive Price.And A Company Called Arvind Limited Was Born. Overnight At Ahmedabad After We Visit Asia`S Bigest MOTHER DAIRY Milk (Bulk Vended Milk) Is Fortified With Vitamin A @2000 IU Per Litre Of Milk As A Part Of Social Accountability. This Program Was Started With The Mother Dairy, Delhi, Since February 1980and There After Mother Dairy Is Continuing This Program On Their Own As A Social Responsibility Without Having Any Financial Assistance From The Government As Well As Since It Is Felt That BVM Is Generally Consumed By The Middle / Lower Middle / Poor Strata Of The Society. It Is Also Found That The Dietary Practices Adopted By These Classes Are Deficient In Vitamin A. Mother Dairy Sources Significant Part Of Its Requirement Of Liquid Milk From Dairy Cooperatives. Overnight At Ahmedabad. (B, L, D). DAYS - 09 AHMEDABAD – GANDHINAGAR –AHMEDABAD Brekfast At Hotel After Proceed To Visit AHMEDABAD LOCAL SIGHTSEEING And After Noon Proceed GANDHINAGAR AKSHARDHAM MANDIR Via Adalaj Step Well & Overnight At Ahmedabad (B, L, D). DAYS - 10 AHMEDABAD – AMUL DAIRY – BADODA After Breakfast We Visit Of AMUL DAIRY AT ANAND The Seeds Of This Unusual Saga Were Sown More Than 65 Years Back In Anand, A Small Town In The State Of Gujarat In Western India. The Exploitative Trade Practices Followed By The Local Trade Cartel Triggered Off The Cooperative Movement. Angered By Unfair And Manipulative Practices Followed By The Trade, The Farmers Of The District Approached The Great Indian Patriot Sardar Vallabhbhai Patel For A Solution. He Advised Them To Get Rid Of Middlemen And Form Their Own Co-Operative, Which Would Have Procurement, Processing And Marketing Under Their Control. - At His Instance In 1965 The National Dairy Development Board Was Set Up With The Basic Objective Of Replicating The Amul Model. Dr. Kurien Was Chosen To Head The Institution As Its Chairman And Asked To Replicate This Model Throughout The Country. Overnight At Baroda. (B, L, D). DAYS:-11 BARODA-ANKLESHWAR-SURAT After Breakfast We Proceed To Ankleshwar Visit Of ASIAN PAINTS India’s Largest Paint Company And Asia’s Third Largest Paint Company, With A Turnover Of Rs 96.32 Billion. The Group Has An Enviable Reputation In The Corporate World For Professionalism, Fast Track Growth, And Building Shareholder Equity. Asian Paints Operates In 17 Countries And Has 23 Paint Manufacturing Facilities In The World Servicing Consumers In Over 65 Countries. Besides Asian Paints, The Group Operates Around The World Through Its Subsidiaries Berger International Limited, Apco Coatings, SCIB Paints And Taubmans. Overnight At Surat. (B, L, D) DAYS:- 12 SURAT After Breakfast We Proceed To Visit The Largest MARKET Of DIAMOND Polishing, Cutting And Crafting In The Whole World. Availability Of Skilled But Low Waged Workers And The Presence Of International Market Have Earned World Wide Fame For The Surat Diamonds. Although India Produces A Very Negligible Amount Of Diamonds, The Country Dominates The World’s Diamond Polishing Industry. Despite The Fact That Bombay Is The Commercial Center Of India’s Diamond Trade, Surat With Its Advantages Has Emerged As The Hot Spot Of The Diamond Industry.After Visit GARDEN TEXTILE MILL & TEXTILE MARKET Industry In Surat Is Mainly Engaged In The Activities Of Yarn Production, Weaving, Processing As Well As Embroidery. Surat Is Well Known For Its Synthetic Products Market. It Is Mainly Engaged In The Production And Trading Of Synthetic Textile Products. Nearly 30 Million Metres Of Raw Fabric And 25 Million Metres Of Processed Fabric Are Produced In Surat Daily. The City Has Several Textile Markets That Exist Since Times Immemorial. Zampa Bazaar, Bombay Market, JJ Textile Market And Jash Market Are Among Them. Katat Gam, Magdalla And Udhana Are The Areas Of Surat Where Manufacturing Is Mainly Concentrated. In The Course Of Time, People From Various Other Places Like Rajasthan And Kolkata Settled In Surat In Order To Carry Out Their Textile Business. The Famous Brands Of Garden And Vimal Textiles Evolved From Surat.A Few Other Brands Like Parag And Prafful From Surat Did Become Famous For A Short Time, But Failed To Create A Lasting Impression In The Market. The Main Market For Surat�S Textile Products Are India And Other Asian Countries.Around 90% Of Polyester Used In India Comes From Surat. However, International Demand For Its Products Is Not Very Significant. The Middle East Is The Major Export Market For Surat�S Textile Products. According To Experts, More Improvisation In The Quality Is Required To Cater To The Demands Of The International Market.Overnight At Surat (B, L, D). After Breakfast Visit The Reliance Industries Hazira Complex Near Surat In Gujarat Is Situated On Approximately 1000 Acres Land Near The Banks Of River Tapi And Manufactures A Wide Range Of Polymers, Polyesters, Fibre Intermidiates And Petrochemicals. Departure Your Final Destination With Sweet Memories!!!! (B, L).