BHP Billiton Safe Growth The world`s largest diversified resources

advertisement

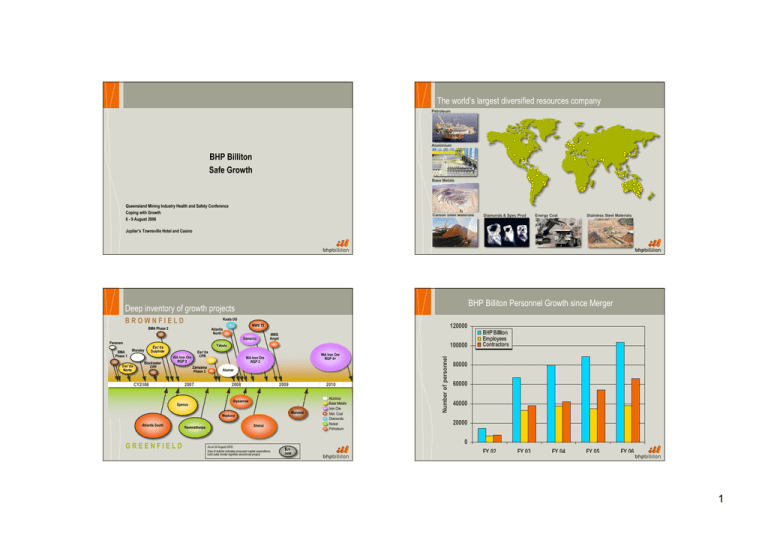

The world’s largest diversified resources company Petroleum Aluminium BHP Billiton Safe Growth Base Metals Queensland Mining Industry Health and Safety Conference Coping with Growth 6 - 9 August 2006 Carbon Steel Materials Diamonds & Spec Prod Energy Coal Stainless Steel Materials Jupiter’s Townsville Hotel and Casino BHP Billiton Personnel Growth since Merger Deep inventory of growth projects BROWNFIELD Koala UG BMA Phase 2 Samarco BMA Phase 1 Esc’da Norte Blackwater CPP 100000 Yabulu Esc’da Sulphide Worsley NWS Angel Esc’da CPR WA Iron Ore RGP 2 Zamzama Phase 2 CY2006 2007 Spence WA Iron Ore RGP 4+ WA Iron Ore RGP 3 Alumar 2009 2008 Stybarrow Maruwai Neptune Atlantis South GREENFIELD Ravensthorpe 2010 Shenzi As at 24 August 2005 Size of bubble indicates proposed capital expenditure; bold outer border signifies sanctioned project Alumina Base Metals Iron Ore Met. Coal Diamonds Nickel Petroleum Number of personnel Paranam 120000 NWS T5 Atlantis North BHP Billiton Employees Contractors 80000 60000 40000 20000 0 $US 200M FY 02 FY 03 FY 04 FY 05 FY 06 1 Where Health, Safety, Environment & Community ‘HSEC’ fits within the BHP Billiton Strategic Framework BHP Billiton Classified Injury Frequency Rate (CIFR) Performance July 2001 - June 2006 The Zero Harm Journey ! Fatality Drivers 5.00 Environment Community Ensure that our activities continually strive for zero harm to our environment Ensure that the communities in which we operate value our citizenship Journey Elements G Time H Time S Time Value Creation ‘Safety and the Environment – An overriding commitment to health, safety, environment responsibility and sustainable development” Safety Provide a workplace where people are able to work without being injured Harm 6.00 Health Our people are not exposed to or come in contact with substances or emissions that harm their health Harm 7.00 12 Month Moving Average 3 Month Moving Average Governance Strong governance to ensure that our reputation and shareholders are secure Harm CIFR 8.00 Harm 9.00 E Time C Time 4.00 3.00 CoPs Networks 2.00 Toolkits 1.00 Guidelines Procedures Jul-01 Aug-01 Sep-01 Oct-01 Nov-01 Dec-01 Jan-02 Feb-02 Mar-02 Apr-02 May-02 Jun-02 Jul-02 Aug-02 Sep-02 Oct-02 Nov-02 Dec-02 Jan-03 Feb-03 Mar-03 Apr-03 May-03 Jun-03 Jul-03 Aug-03 Sep-03 Oct-03 Nov-03 Dec-03 Jan-04 Feb-04 Mar-04 Apr-04 May-04 Jun-04 Jul-04 Aug-04 Sep-04 Oct-04 Nov-04 Dec-04 Jan-05 Feb-05 Mar-05 Apr-05 May-05 Jun-05 Jul-05 Aug-05 Sep-05 Oct-05 Nov-05 Dec-05 Jan-06 Feb-06 Mar-06 Apr-06 May-06 Jun-06 0.00 Puts Near Miss as % of total Significant Incident Significant Incident Reporting Growth Reports FY 03 to FY 06 % Nearmiss reports of total SIs 100 2500 90 2000 Percentage Near Miss Reports • Review of our fatal accident history and significant incidents identified key areas of risk to our people, which require specific controls to eliminate the incidents that could cause fatalities • Fatal Risk Control Protocols (FRCPs) to deal with these risk areas were developed through workgroups made up of individuals from across the Company, with extensive experience in our operations • The FRCPs apply: – at all BHP Billiton controlled sites and controlled activities – to all employees, contractors and visitors when involved in controlled activities • Each FRCP is classified into three board focus areas, detailing the essential controls that are to be in place to manage the risk: – Plant and equipment requirements – Procedural requirements – People requirements Significant Incident Reporting Maturity Near Miss Reports Number of Reports Policy in Action – Fatal Risk Control Protocols Total SI Reported 1500 1000 500 80 70 60 50 40 30 20 10 0 0 FY 03 FY 04 FY 05 FY 06 FY 03 FY 04 FY 05 FY 06 2 Zero Barrier Incidents Zero Barrier Alerts What is a Zero Barrier Incident These incidents reflect high awareness and mature reporting culture A Zero Barrier incident is an incident where no key barriers or defences remained to prevent an actual Significant Outcome. These incidents reflect a serious breakdown in preventative systems They represent "close call” incidents where: • All the key barriers and defences have been breached, our systems and behaviours have failed Zero Barrier Incident • An event has occurred usually involving the release of uncontrolled energy • It is only by chance that a more severe outcome did not eventuate. Barriers Latent Safety Awards and Recognition Recognition and reward form an important element of any successful safety program. The annual HSEC Awards recognise innovations and individual effort contributing to our HSEC improvement and drive towards Zero Harm. No risk assessment completed for WAH activity Person observed at Permit to work not Person observed completed prior to working at height with imminent risk of fall from heights with no working at height inadequate fallfall-restraint restraint Time Person standing on hand rail, not wearing fall- restraint falls 3 metres Immediate Safety Awards and Recognition The Safety Excellence Awards are a complementary company-wide program that supports and recognises overall sites who have excelled in safety. 3