2013 sustainability report

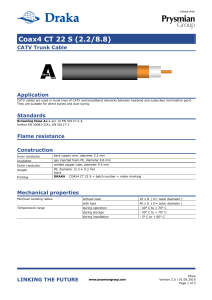

advertisement