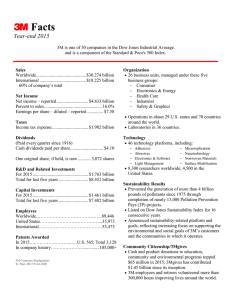

2015 Sustainability Report

advertisement