E3.04-05/2010

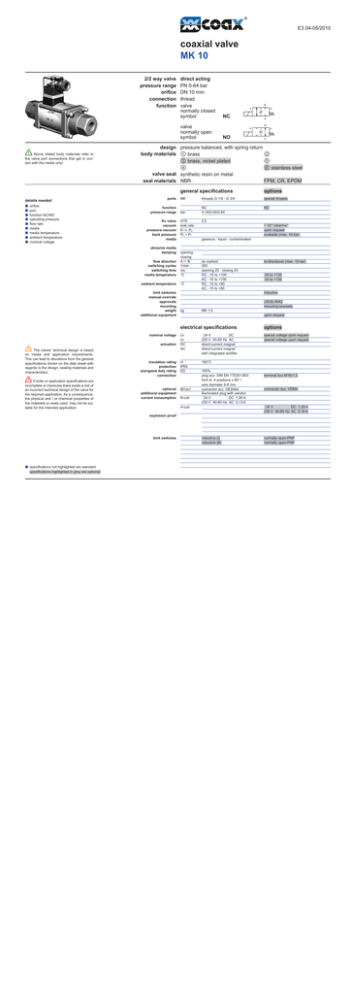

coaxial valve

MK 10

2/2 way valve

pressure range

orifice

connection

function

direct acting

PN 0-64 bar

DN 10 mm

thread

valve

normally closed

symbol

valve

normally open

symbol

Above stated body materials refer to

the valve port connections that get in contact with the media only!

■ orifice

■ port

■ function NC/NO

■ operating pressure

■ flow rate

■ media

■ media temperature

■ ambient temperature

■ nominal voltage

NC

A

NO

④

⑥ stainless steel

FPM, CR, EPDM

general specifications

options

threads G 1/4 - G 3/4

special threads

function

pressure range

bar

NC

0-16/0-40/0-64

NO

Kv value

vacuum

pressure-vacuum

back pressure

media

limit switches

manual override

approvals

mounting

weight

additional equipment

m³/h

leak rate

P1 P2

P2 > P1

opening

closing

AB

1/min

ms

°C

°C

kg

2,5

gaseous - liquid - contaminated

as marked

200

opening 25 closing 25

DC: -10 to +100

AC: -10 to +100

DC: -10 to +80

AC: -10 to +80

MK 1,5

< 10-6 mbar•l•s-1

upon request

available (max. 16 bar)

bi-directional (max. 16 bar)

-30 to +120

-30 to +120

inductive

LR/GL/WAZ

mounting brackets

upon request

electrical specifications

options

Un

Un

DC

AC

24 V

DC

230 V 40-60 Hz AC

direct-current magnet

direct-current magnet

with integrated rectifier

special voltage upon request

special voltage upon request

insulation rating

protection

energized duty rating

connection

H

IP65

ED

180°C

optional

additional equipment

current consumption

M12x1

nominal voltage

actuation

N-coil

H-coil

100%

plug acc. DIN EN 175301-803

form A, 4 positions x 90° /

wire diameter 6-8 mm

connector acc. DESINA

illuminated plug with varistor

24 V

DC 1,00 A

230 V 40-60 Hz AC 0,13 A

explosion proof

limit switches

specifications highlighted in grey are optional

A

MK

ambient temperature

■ specifications not highlighted are standard

b

a b

ports

flow direction

switching cycles

switching time

media temperature

If order or application specifications are

incomplete or imprecise there exists a risk of

an incorrect technical design of the valve for

the required application. As a consequence,

the physical and / or chemical properties of

the materials or seals used, may not be suitable for the intended application.

B

a

design pressure balanced, with spring return

body materials ① brass

②

③ brass, nickel plated

⑤

abrasive media

damping

The valves‘ technical design is based

on media and application requirements.

This can lead to deviations from the general

specifications shown on the data sheet with

regards to the design, sealing materials and

characteristics.

b

a b

valve seat synthetic resin on metal

seal materials NBR

details needed

B

a

inductive (I)

inductive (B)

terminal box M16x1,5

connector acc. VDMA

24 V

DC 1,29 A

230 V 40-60 Hz AC 0,16 A

normally open-PNP

normally open-PNP

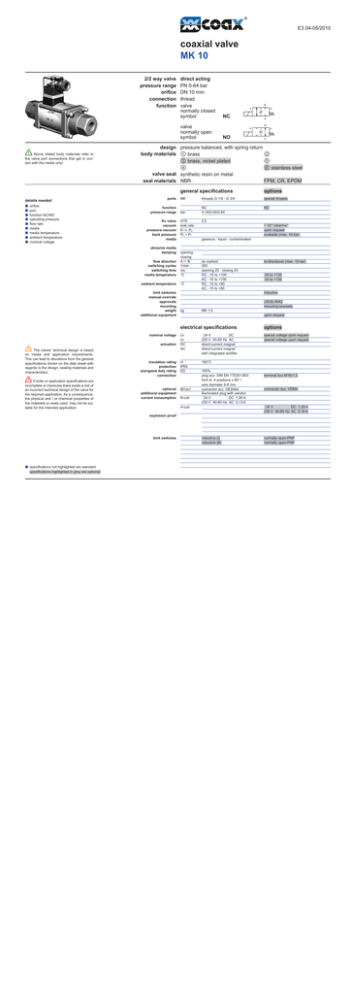

type MK 10

��

��

����

�

�

�

�����

��

��

function:

NC

closed when not energized

�

��

��

�����

constructive length

type MK 10

L1

L2

0-16/0-40 bar

113,5

23

0-64 bar

121,5

19

��

��

����

�

�

�

�����

��

��

function:

NO

open when not energized

�

��

�����

��

The applic ation - specif ic layout relating to temperature, pressure c onditions, switching behavior, media and its c on sistency may restrict the range of use or nec essitate relevant modif ic ations to materials used and seal ar rangements.

Rights

reserved

to

make

technical

alterations

•

Not

responsible

for

printing

errors

•

Detailled

drawings

can

be

obtained

upon

request