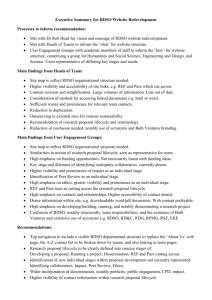

technical diary 2008 - Civil Engineering Portal

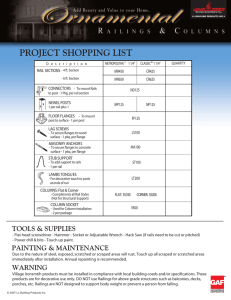

advertisement