This Addendum contains the following information

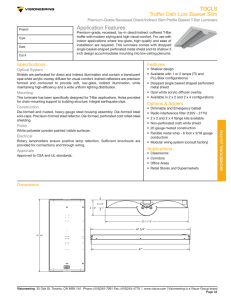

advertisement