User Manual Rev082115

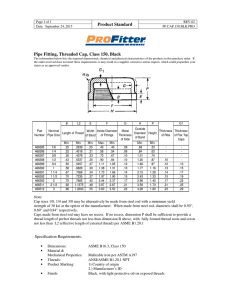

advertisement