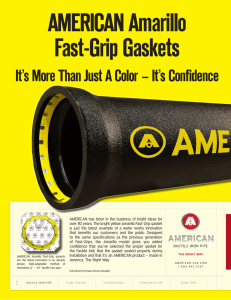

gasket

advertisement