2000-01-1953 Comparison of Chemical Kinetic Mechanisms in

advertisement

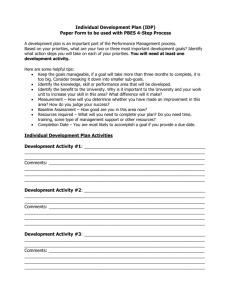

SAE TECHNICAL PAPER SERIES 2000-01-1953 Comparison of Chemical Kinetic Mechanisms in Simulating the Emission Characteristics of Catalytic Converters Tariq Shamim, Huixian Shen and Subrata Sengupta The University of Michigan - Dearborn Reprinted From: Advanced Emissions Aftertreatment for Gasoline Applications (SP–1544) and International Spring Fuels & Lubricants Meeting & Exposition Paris, France June 19-22, 2000 400 Commonwealth Drive, Warrendale, PA 15096-0001 U.S.A. Tel: (724) 776-4841 Fax: (724) 776-5760 The appearance of this ISSN code at the bottom of this page indicates SAE’s consent that copies of the paper may be made for personal or internal use of specific clients. This consent is given on the condition, however, that the copier pay a $7.00 per article copy fee through the Copyright Clearance Center, Inc. Operations Center, 222 Rosewood Drive, Danvers, MA 01923 for copying beyond that permitted by Sections 107 or 108 of the U.S. Copyright Law. This consent does not extend to other kinds of copying such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale. SAE routinely stocks printed papers for a period of three years following date of publication. Direct your orders to SAE Customer Sales and Satisfaction Department. Quantity reprint rates can be obtained from the Customer Sales and Satisfaction Department. To request permission to reprint a technical paper or permission to use copyrighted SAE publications in other works, contact the SAE Publications Group. All SAE papers, standards, and selected books are abstracted and indexed in the Global Mobility Database No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher. ISSN 0148-7191 Copyright © 2000 CEC and SAE International. Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE. The author is solely responsible for the content of the paper. A process is available by which discussions will be printed with the paper if it is published in SAE Transactions. For permission to publish this paper in full or in part, contact the SAE Publications Group. Persons wishing to submit papers to be considered for presentation or publication through SAE should send the manuscript or a 300 word abstract of a proposed manuscript to: Secretary, Engineering Meetings Board, SAE. Printed in USA 2000-01-1953 Comparison of Chemical Kinetic Mechanisms in Simulating the Emission Characteristics of Catalytic Converters Tariq Shamim, Huixian Shen and Subrata Sengupta The University of Michigan - Dearborn Copyright © 2000 CEC and SAE International. an important role in such design modification efforts. In addition to proper and accurate flow, heat and mass transfer models, the accuracy of numerical simulations depend on the accurate description of chemical kinetic mechanisms. ABSTRACT Engine exhaust systems need to undergo continuous modifications to meet increasingly stricter regulations. In the past, much of the design and engineering process to optimize various components of engine and emission systems has involved prototype testing. The complexity of modern systems and the resulting flow dynamics, and thermal and chemical mechanisms have increased the difficulty in assessing and optimizing system operation. Due to overall complexity and increased costs associated with these factors, modeling continues to be pursued as a method of obtaining valuable information supporting the design and development process associated with the exhaust emission system optimization. Several chemical reaction mechanisms are available in literature. Oh and Cavendish [1] used a three step reaction mechanism. Their model only considered oxidation processes of CO, HC, and H2. They assumed that HC oxidation is represented by the reaction of propylene (“fast-oxidizing HC”) and neglected other HC as insignificant influence on the converter thermal performance. Siemend et al. [2] used similar oxidation kinetic rates in their study of comparison between model simulations and experiments. In addition to oxidation, their reaction mechanism also includes the NO reduction. The rate expression for NO reduction by CO was taken from Subramanian and Verma [3,4]. In both models, all unburned hydrocarbons are represented by CHy (y is the ratio of hydrogen to carbon in the fuel). The heat of formation of CHy was assumed to be one-third of C3H6. Due to its simplicity and good accuracy, the 4-step mechanism is widely used in simulating the catalyst performance. However, this mechanism ignores the variation in the reaction rates of several HC species by lumping them into one category. It also ignores the effect of water gas shift and steam reforming effects, which become especially important under sever transient driving conditions. Insufficient kinetic mechanisms and the lack of adequate kinetics data are major sources of inaccuracies in catalytic converters modeling. This paper presents a numerical study that investigates the performance of different chemical mechanisms in simulating the emission conversion characteristics of catalytic converters during both steady state and transient conditions. The model considers the coupling effect of heat and mass transfer with the catalyst reactions as exhaust gases flow through the catalyst. The heat transfer model includes the heat loss due to conduction and convection. The effect of radiation is assumed to be negligible and is not considered. The resulting governing equations based on the conservation of mass, momentum and energy are solved by a tridiagonal matrix algorithm (TDMA) with a successive line under relaxation method. The performance of different chemical kinetic schemes is reviewed by comparing the results of numerical model with the experimental measurements. An improvement in the reaction mechanisms may be made by lumping several HC species into more than one category. Koltsakis et al. [5] used a six-step chemical mechanism to describe the chemical reactions occurring on the surface of the automotive catalyst. Their model assumed the HC to be lumped into two categories: fast burning and slow burning. In addition to the oxidation and reduction processes, they also considered the steam reforming reaction. This reaction was attributed to high HC conversion efficiencies in fresh catalysts during operation in rich exhaust. Similar to most of the previous studies, their kinetic expressions were of the form proposed by Votz et al. [6]. They employed a tunable factor to match their NO reduction rate with the INTRODUCTION Catalytic converters have been employed in vehicles for decades and have been proven to be very successful in reducing the exhaust emissions. However, with the worldwide trend of stringent emission regulations, their designs need to undergo continuous modifications. Mathematical modeling and numerical simulations play 1 The gas phase species equation: experimental measurements. A more detailed kinetic mechanism was proposed by Otto and LeGray (7), which was later modified to include an elaborate NOx mechanism and the formation of ammonia and its effect on NO oxidation under fuel-rich conditions. A methodology for updating steady-state kinetic data for this 13-step reaction mechanism was presented by Montreuil et al [8]. These kinetic rate expressions are to date the most detailed. In this mechanism, all the unburnt hydrocarbons are lumped into three categories: fast burning, slow burning, and inert. The mechanism has been found to simulate the performance of catalytic converters fairly well under both steady state and transient conditions [9]. However, the use of these detailed kinetic rate expressions require the knowledge of 97 constants, which requires detailed experimentation for different type of catalysts. (ε ∂C gj ∂t + vg ∂C gj ∂z ) = − km j G a (C gj − C sj ) (3) where the superscript j varies from 1 to 7 representing, respectively, following gas species: CO, NO, NH3, O2, C3H6, H2 and C3H8. The surface species equation: ∂C sj N = km j Ga (C gj − C sj ) − Ga R j (Ts , C 1s ,⋅ ⋅ ⋅ ⋅ ⋅⋅, C c species ) ∂t (4) (1 − ε ) where superscript j varies from 1 to 7 representing the surface species in the same order as the gas phase species equation. Even though all of the chemical reaction models mentioned above are applied to catalyst simulations, there exist differences in catalyst performance predictions because of variations in the chemical mechanisms. However, it is difficult to isolate the effect of chemical mechanism by simply comparing the above studies. As the differences in catalyst performance prediction may also be attributed to the differences in these studies related to test conditions, heat and mass transfer modeling, catalyst conditions, etc. The present study was motivated by recognizing the need for a systematic evaluation of the existing chemical reaction schemes under similar and realistic conditions. The study compares the performance of various mechanisms in simulating the catalyst operation during both steady and transient conditions. The model predictions were compared with experimental measurements. The transient conditions were simulated by considering the catalyst operation during the US Federal Test Procedure (FTP). In addition to the comparison, the study also identifies the salient feature of each mechanism. It is anticipated that this sensitivity study will lead to efforts in modifying or devising a better chemical catalyst mechanism. CHEMICAL REACTION MECHANISMS – As described in the Introduction, the present study considers several different chemical reaction mechanisms existing in literature. A brief description of these mechanisms is listed below: MATHEMATICAL FORMULATION where 3-Step Chemical Reaction Mechanism – This reaction mechanism, listed below, was proposed by Seh Oh and co-workers [1,10] 1 O 2 → CO2 2 CO + C3 H 6 + H2 + 9 O2 → 3CO2 + 3H 2 O 2 1 O2 → H 2O 2 QR = -2.832*105 (J/mol) QR = -1.928*106 (J/mol) QR = -2.42*105 (J/mol) The expressions for reaction rates are as following: R1 = k1C CO C O2 / G R 2 = k 2 C C3 H 6 C O2 / G R3 = k1C H 2 C O2 / G GOVERNING EQUATIONS – The governing equations, as listed below, were developed by considering the conservation of mass, energy and chemical species. k1 = 6.699 × 109 exp(−12556 / TS ) mol / cm 2 ⋅ s k 2 = 1.392 ×1011 exp(−14556 / TS ) mol / cm 2 ⋅ s The gas phase energy equation: 2 G = T S (1 + K 1 C CO + K 2 C C 3 H 6 ) 2 (1 + K 3 C CO C C2 3 H 6 ) ∂T g ρ g C Pg (ε ∂t + vg ∂T g ∂z ) = − h g G a (T g − T s ) 0 .7 (1 + K 4 C NO ) (1) The surface energy equation: (1−ε)ρsCPs + Ga ∂Ts ∂T = (1−ε)λs 2s + hgGa (Tg −Ts ) − h∞Sext(Ts −T∞) ∂t ∂z 2 nreaction ∑R (T ,C ,⋅⋅⋅⋅⋅⋅,C j s j=1 1 s nspecies ) ⋅ ∆H j s (2) 2 K1 = 65.5EXP (961 / TS ) dimensionless K 2 = 2.08 × 10 3 EXP (361 / TS ) dimensionless K 3 = 3.98 EXP (11611 / T S ) dimensionless K 4 = 4.79 × 10 5 EXP ( −3733 / TS ) dimensionless α ⋅ H 2O 2 α CH α + M 2 ⋅ O 2 → CO + ⋅ H 2 O 2 4-Step Chemical Reaction Mechanism – A widely used reaction scheme considers the above three reactions with the NO reduction by CO. The resulting 4-step mechanism has been shown to simulate the catalyst reactions with a reasonable accuracy [2]. The NO reduction used in this mechanism is as follows: CO + NO = CO 2 + 1 N2 2 CH α + M 1 ⋅ O2 → CO2 + H2 + QR = -3.73*105 (J/mol) R4 = TS−0.17 (T + k 5CCO ) 2 mole / cm 2 ⋅ s k 5 = 1.2028 × 10 5 EXP (653 .5 / T S ) H 2 + NO → H 2 O + K 1 N2 2 1 N2 2 2.5 H 2 + NO → NH 3 + H 2 O Modified 4-Step Chemical Reaction Mechanism – This reaction mechanism is essentially similar to the 4-step mechanism described previously. The only difference is the modification in the rate expression of NO reduction. Based on the comparison with the experimental measurement, the authors modified the exponent of CO concentration in the rate expression R4 from 1.4 to 1.9. The modified reaction rate of NO reduction is as following: CH α + M 1 ⋅ O 2 → CO 2 + α ⋅ H 2O 2 α 1 1 1 CHα + NO → CO + H 2O + N 2 2M 2 2M 2 4M 2 2 CH α + M 3 ⋅ NO → CO 2 + M α ⋅ H20 + 3 ⋅ N2 2 2 2.5 (3 − α ) 2.5 CHα + NO + H 2O → NH3 + CO 2M 2 4M 2 2M 2 1.9 0.3 0.13 k 4 CCO CO2 C NO TS−0.17 (T + k 5CCO ) 2 (HCS) (HCF) (HCF) (HCF) (5) where α = Hydrogen-to-Carbon ratio, and M 1 = [1 + 5-Step Chemical Reaction Mechanism – This mechanism was obtained by adding the steam reforming reaction in the above modified 4-step reaction scheme. The steam reforming reaction and its rate expression used, as shown below, are similar to those used by Koltsakis et al. [5]. C 3 H 6 + 3H 2 O = 3CO + 6 H 2 1 N2 2 2.5CO + NO + 1.5H 2 O → NH 3 + 2.5CO 2 + k 4 = 3.067 × 10 8 EXP ( −8771 / T S ) R4 = 3 1 O 2 → 1.5H 2 O + N 2 4 2 CO + NO → CO2 + 1.4 0.3 0.13 k 4 CCO CO2 C NO (HCF) 1 O2 → H 2O 2 NH 3 + And the reaction rate expressions for the above reactions is: (HCF) 1 α α α ] M 2 = [ + ] M 3 = [2 + ] 4 ; 2 4 ; 2 HCF = Fast burning HC; HCS = Slow burning HC. The corresponding reaction rate expressions are listed elsewhere [9]. For different catalyst formulations, the coefficients in the reaction rate expressions are different. They also vary with the aging of catalytic converters. The present study uses a palladium-based catalyst. The coefficients in the reaction rate expressions were taken from Montreuil et al. [8] wherein they were appropriately adjusted using experimental flow reactor measurements. QR = 3.7346*105 (J/mol) And the reaction rate expression: R 5 = k 5 C C 3 H 6 C H 2O / G k 5 = 1 .7 × 10 12 EXP (12629 / T S ) OXYGEN STORAGE MECHANISM – The conversion efficiency of a three-way catalytic converter can be improved by storing the extra oxygen under fuel lean conditions and releasing it under rich conditions [11,12]. The released oxygen may participate in the reactions with the reducing agents, thereby increasing the conversion of CO and HC in a rich exhaust-gas environment [13-15]. Such an oxygen storage capacity (OSC) is developed in the modern catalyst by coating its substrate with a wash-coat material containing ceria. 13-Step Chemical Reaction Mechanism – This mechanism consists of 13 independent forward pathways for oxidation of CO, H2, C3H6, C3H8, and NH3 with O2 and NO as oxidizing agents, and their corresponding rich and lean kinetic rate expressions. This chemical reaction scheme and kinetic data were originally presented by Otto and LeGray [7] and later presented with the modified kinetic data by Montreuil et al. [8]. The reaction scheme is shown as follows: 1 CO + O2 → CO2 2 3 The oxygen storage and release mechanism used in this study was modeled by a 9-step site reaction mechanism. This mechanism was developed by designating two kinds of sites that can be oxidized and reduced through a 9 step site reaction mechanism [14]. The reduced metal site on the surface is defined as <S> and the oxidized site is defined as <OS>. This 9 step reaction mechanism is listed as following: implicit difference scheme in the spatial direction. Since more chemical reactions take place near the inlet, smaller grid spacing was used near the inlet and larger spacing near the exit. A standard tridiagonal matrix algorithm (TDMA) with an iterative successive line under relaxation method was used to solve the finite difference equations. Details of the solution procedure are described elsewhere [9]. 1 < S > + O2 →< OS > 2 RESULTS AND DISCUSSION Site Oxidation < OS > + CO →< S > + CO 2 The performance of different chemical mechanisms was assessed by comparing the numerical predictions with the experimental measurements under both steady and transient conditions. The converters used for both steady state and transient performance assessment were palladium-based catalysts. For the steady state case, the catalyst has a length of 3.81 cm, cross-sectional area of 5.0671x10-4 m2, cell density of 620,000 cell/m2, and wall thickness of 1.88x10-4 m. And the feed gas composition was 1% CO, 0 ppm CH4, 1000 ppm C3H6, 500 ppm C3H8, and 1000 ppm NO. The feed gas temperature was 371 °C, and space velocity of 50,000 hr-1. For the transient case, the catalyst used has a length of 8.001 cm, cross-sectional area of 8.69254x10-3 m2, cell density of 620,000 cell/m2, and wall thickness of 1.905x10-4 m. Site reduction by CO H 2 O + CO → H 2 + CO 2 Water-Gas shift < OS > + H 2 →< S > + H 2 O CH α + H 2 O → CO + (1 + Site reduction by H2 α ) ⋅ H2 2 Steam reforming 3 1 3 CH α + < OS >→< S > + C + CO + ( α ) H 2 2 2 4 Reduction by HC C + O 2 → CO 2 Coke Burn-off < S > + NO →< OS > + < OS > + 1 N2 2 NO Storage 2 2 3 NH 3 →< S > + NO + H 2 O 5 5 5 STEADY STATE PERFORMANCE – The steady state performance of the reaction mechanisms was assessed by comparing the model results with the experimental measurements of Montreuil et al. [8]. For this case, all transient terms in the governing equations were set to be zero. Figure 1 shows the comparison of the converter pollutant conversion efficiencies as predicted by different chemical mechanisms. Here, the conversion efficiencies are plotted as a function of redox ratio, which is defined as: NH3 Site reduction where α is hydrogen-to-carbon ratio of the hydrocarbon. Each reaction has two rate expressions, one being the fast site rate expression and another the slow site rate expression. The total sites are conserved for both fast site and slow site. Therefore, S total , f =< S > f + < OS > f S total , s =< S > s + < OS > s (7) Redox Ratio = The rates of the transient reactions are of the form (OXSW ) ⋅ CTR − E / RTs ⋅ Rtransient = ( X si ) EX ( i ) 1 N specie 1+ ∑k n ⋅ X sn n =1 (9) Figure 1a shows the results of the 3-step mechanism. The results depict a good agreement between the model predictions of CO and HC conversion and the experimental measurements. The agreement is particularly excellent in the range of low redox ratio. However, when the redox ratio increases, i.e., in rich mixture zone, the discrepancies between the model predictions and measurements increase. For a wide range of redox ratio greater than unity, the model underpredicts the CO conversion. The HC conversion is also initially slightly underpredicted. However, beyond redox ratio of 2.5, the model overpredicts HC conversion efficiency. The overall prediction of HC conversion is better than that of CO. The NO conversion, as mentioned earlier, is not included in this mechanism. The elimination of NO reaction may have some influence on the model prediction of CO and HC. N specie ∏ α )[ HC ] 4 [ NO ] + 2 ⋅ [ O 2 ] [ CO ] + [ H 2 ] + 6 ⋅ ( 1 + (8) where OXSW =1, if Redox ratio <1 OXSW =0, if Redox ratio >1 The corresponding coefficients for calculating the transient reaction rates are based on experimental data. SOLUTION PROCEDURE – The governing equations were discretized by using a non-uniform grid and employing the control volume approach with the central 4 redox ratio of 1.1 and 2.5. Beyond this value, the conversion is underpredicted by the mechanism. The model prediction of HC conversion is similar to the 3-step mechanism, and has good agreement with measurements. The HC conversion efficiency is slightly overpredicted for redox ratio greater than unity. Figure 1a. Comparison of 3-step model results with experimental measurements under steady state condition Figure 1b shows the results of the 4-step mechanism, which was obtained by adding the NO reduction reaction in the previous 3-step mechanism. For redox ratios greater than unity, the results show an excellent match between the model NO prediction and the experimental measurement. However, the NO prediction for redox ratio less than unity is very inaccurate. The addition of NO reaction also significantly influences the CO and HC conversion rates. It increases the conversion rates of both HC and CO. The results show large differences between the model predictions and the measurements. These discrepancies are due to inaccuracies in the model of NO reduction reaction. Figure 1c. Comparison of modified 4-step model results with experimental measurements under steady state condition Figure 1d shows the results of the 5-step mechanism. This chemical scheme, as mentioned earlier, was obtained by adding a steam reforming reaction to the modified 4-step mechanism. The reaction rate expression for the steam reforming was obtained from literature [15]. The rate expressions for other reactions were similar to that of the modified 4-step. The results show that the model prediction of NO emission remains excellent and is not much influenced by steam reforming reaction. The major influence of steam reforming is found to be on HC emission. As expected, the results show an improvement in HC conversion efficiency due to steam reforming reaction. With the overprediction of HC conversion, the agreement between the model prediction and measurement is reduced. The prediction of CO conversion, however, is improved especially for the redox ratios between 1.1 and 2.5. Figure 1b. Comparison of 4-step model results with experimental measurements under steady state condition Figure 1c shows the results of the modified 4-step mechanism. Except for a slight modification in the reaction rate of NO, this mechanism including the reaction rates and other kinetic data is essentially similar to the previously discussed 4-step mechanism. The modification in the NO rate expression, as mentioned earlier, is made by changing the exponent of CO concentration from 1.4 to 1.9. The figure depicts a much better agreement between the model and the measurements. The prediction of NO conversion is particularly excellent over a wide range of redox ratio. The prediction of CO conversion also shows improvement. It matches very well with the measurements in the vicinity of redox ratio of unity. The CO conversion is slightly overpredicted between the Figure 1d. Comparison of 5-step model results with experimental measurements under steady state condition The results of the model with the 13-step chemical mechanism are shown in Figure 1e. The figure depicts that the model predictions, particularly at low redox ratios, are in good agreement with the measurements. 5 results of the 13-step mechanism may indicate a transient phenomenon that is not captured well by both the 4-step chemistry and the measurements that were limited by 1 Hz. The measurements with higher resolution are needed to clarify this point. NO prediction is excellent over a wide range of redox ratios. The predictions of CO and HC, however, are not as good as those of 3 or 4 step mechanisms. For redox ratios greater than unity, the model significantly underpredicts the CO conversion and overpredicts the HC conversion. One reason for such a disagreement is the inaccuracy in chemical kinetic data, which are obtained by comparing with the actual measurements during engine operation. Since the engine operating conditions are in the close vicinity of redox ratio of unity, the constants and the rate expressions are tuned to better simulate the converter performance under these conditions. Hence the model can be used with a good accuracy to simulate the converter performance under normal engine operating conditions. However, a modification of its rate expressions will be required if the mechanism is employed to simulate the converter subjected to highly fuel rich conditions. Figure 2a. Comparison of transient output HC emissions with experimental measurements Figure 1e. Comparison of 13-step model results with experimental measurements under steady state condition Figure 2b. Comparison of accumulated HC with experimental measurements TRANSIENT PERFORMANCE – The steady state performance results clearly show that the modified 4-step mechanism is better than the 3-step mechanism. The modified mechanism also simulates the NO conversion in addition to embodying all the other features of the 3-step mechanism. Hence, the assessment of the transient performance of different mechanisms was limited to the modified 4-step and the 13-step mechanisms. The transient conditions were simulated by considering the converter performance during the US Federal Test Procedure (FTP). Figure 2b depicts the accumulated HC emission during the first 100 seconds of the FTP. The 4-step chemistry predicts less HC emission than the 13-step mechanism, and its predictions are closer to the experimental measurements. Both mechanisms, however, underestimate the catalyst HC conversion performance. A major reason for this discrepancy is that the simulations do not take into account the effect of oxygen storage capacity, which significantly improves the converter performance during the rich operating conditions. The effect of this mechanism is discussed in the later section. The converter HC conversion efficiency during the whole FTP cycle is measured to be 95.88%, compared to 80.37% and 85.14% predicted respectively by the 4-step and the 13-step mechanisms. Figure 2a shows the comparison of instantaneous HC emissions as determined by measurements and predictions by using the modified 4-step and the 13-step reaction schemes. The figure depicts a reasonable overall agreement between both model predictions and the measurements. Both of the mechanisms capture the major trends of HC emissions. The relatively large production of HC at the initial stage of cycle corresponds to the cold start conditions. This cold start behavior is also well simulated by both mechanisms. However, the model predictions have more spikes than those shown in measurements. Compared to the 13-step mechanism, the 4-step mechanism shows better agreement with the measurements. The more number of spikes in the Figure 3 shows the instantaneous and accumulated CO emissions. The results show that the instantaneous CO emission is well predicted by both the mechanisms. These models capture the initial high CO production corresponding to cold start conditions, and simulate fairly well the various CO peaks during the FTP cycle. Similar to the HC emission prediction, the CO predictions of the 13-step mechanism have more spikes. The accumulated emission results depict a good agreement between the 6 Figure 3a. comparison of transient output CO emissions with experimental measurements Figure 4a. Comparison of transient output NO emissions with experimental measurements Figure 3b. Comparison of accumulated CO with experimental measurements Figure 4b. Comparison of accumulated NO with experimental measurements measurements and the predictions of the 4-step mechanism. Contrary to the case of HC conversion performance, the models overestimate the converter CO performance. The converter CO conversion efficiency during the whole FTP cycle is measured to be 91.53%, compared to 86.51% and 85.40% predicted respectively by the 4-step and the 13-step mechanisms. developed mainly by coating the catalyst substrate with a washcoat material containing ceria, allows oxygen storage under lean operating conditions and its release under rich conditions. The released oxygen improves the conversion of CO and HC during the rich cycle. During normal driving operation, the OSC plays an important role in improving the converter efficiency since there are continuous oscillations of rich and lean conditions due to rapid fluctuations in air-fuel ratio about stoichiometric conditions. The instantaneous and accumulated NO emissions are shown in Figure 4. The trend of instantaneous NO emission is fairly well predicted by both the 4-step and 13-step mechanisms. However, the 4-step mechanism shows larger spikes than those determined experimentally. Compared to the 4-step, the 13-step mechanism predictions are generally in closer agreement with the measurements. The accumulated NO emission results reveal that the 13-step overpredicts and the 4step underpredicts the converter performance. The converter NO conversion efficiency during the whole FTP cycle is measured to be 92.03%, compared to 86.49% and 95.09% predicted respectively by the 4-step and the 13-step mechanisms. The 4-step and the 13-step mechanisms were compared by adding the OSC. The reaction scheme used for the OSC, as mentioned earlier, was a 9-step mechanism. Figures 5-7 show the accumulated HC, CO, and NO conversions. The results show that the model predictions of both mechanisms are improved by considering the OSC. The prediction of HC conversion especially shows significant improvement. The 13-step mechanism predictions are in excellent agreement with the measurements. The prediction of the 4-step mechanism is also improved, however, not as much as in the case of the 13-step mechanism. The HC conversion efficiency during the whole FTP cycle is 88.15% for the 4-step and 94.84% for the 13-step, compared to 95.88% as determined by measurements. EFFECT OF OXYGEN STORAGE CAPACITY – Most of the modern 3-way catalytic converters have oxygen storage capacity (OSC). This capacity, which is 7 step mechanism is better than that of the 4-step mechanism. The prediction of NO conversion efficiency is not much influenced by the OSC for the 13-step mechanism, and it decreases significantly for the 4-step mechanism. Figure 5. Comparison of accumulated HC with experimental measurements Figure 7. Comparison of accumulated NO with experimental measurements CONCLUSIONS Figure 6. A numerical study was carried out to investigate the performance of different chemical reaction mechanisms under both steady state and transient conditions. The results led to the following conclusions: Comparison of accumulated CO with experimental measurements • The converter steady state performance can be simulated by several different chemical reaction mechanisms. The kinetic expressions of most of these mechanisms are generally tuned to yield optimum model performance near the stoichiometeric conditions. The 3-step mechanism, proposed by Seh Oh, which considers only the oxidation of CO, C3H6, and H2, gives satisfactory results of CO and HC conversion. The NO conversion performance can be obtained by adding the reaction of NO reduction by CO. The resulting 4step mechanism is widely used in simulating the converter performance. A slight modification in the NO reduction rate expression is found to give the best results compared to measurements. Figure 6 shows that the addition of the OSC does not appreciably influence the CO conversion prediction of the 13-step reactions during the first 100 seconds of the FTP. The results of the 4-step mechanism with the OSC show an improvement of the CO conversion performance. However, since the mechanism with no OSC already overpredicts the CO conversion (see Figure 3), addition of the OSC makes the disparity between the model results and the experimental measurements larger. For the total FTP cycle, the OSC improves the CO conversion efficiency, which is underpredicted without OSC by both mechanisms. The CO conversion efficiency is 87.33% for the 4-step and 88.69% for the 13-step, as compared to 91.53% determined by measurements. • The steam reforming reaction is found to mainly influence the HC emission by increasing its oxidation rate. It also affects CO oxidation but does not have much influence on NO reduction. Similar to the case of CO emissions, there is not much influence of the OSC on the NO conversion prediction of the 13-step mechanism at both the beginning of the FTP (Fig.7) and during the whole FTP cycle (the total NO conversion efficiency changing to 95.93%, comparing with 95.09% of no OSC case). With the addition of the OSC, the 4-step mechanism predicts an increase in the NO and underpredicts the NO conversion performance (the total NO conversion efficiency decreasing to 75.38% from 86.49%). Compared to the 4-step, the 13-step mechanism is in closer agreement with the experimental measurements. • The transient performance of reaction mechanisms studied is acceptable. The model predictions with 13-step mechanism have the best agreement with experimental measurements during the whole FTP test. The consideration of the oxygen storage mechanism improves the model predictions of HC and CO conversions for both 13-step and 4-step mechanisms. However, on the NO conversion predictions, it has almost no effect for 13-step mechanism and adverse effect for 4-step mechanism. In addition, the oxygen storage capacity has major influence on HC conversion. In summary, the results show that OSC improves the predictions of total conversion efficiencies of HC and CO during the whole FTP test, and the improvement of 13- 8 12. Taylor, K. C., "Automobile Catalytic Converters", Springer-Verlag, Berlin, Heidelberg, 1984. 13. Herz, R. K., " Dynamic Behavior of Automotive Catalysts. 1. Catalyst Oxidation and Reduction." Ind. Engng Chem. Prod. Res. Dev.20, pp. 451-457, 1981. 14. Li, P., Adamczyk, A. A., and Pakko, J. D., "Thermal Management of Automotive Emission Systems: Reducing the Environmental Impact," The Japan-U. S. Seminar on Thermal Engineering for Global Environment Protection (A-3), 1994. 15. Koltsakis, G. C. and Stamatelos, A. M., “Catalytic Automotive Exhaust Aftertreatment,” Progress in Energy and Combustion Science, v 23 n 1, 1997, pp. 1-39. ACKNOWLEDGMENTS The financial support from the Ford Scientific Research Laboratory, Oak Ridge National Laboratory and the Center for Engineering Education and Practice (CEEP) of the University of Michigan-Dearborn is greatly appreciated.. REFERENCES 1. Oh, S.H. and Cavendish, J.C., "Transients of Monolithic Catalytic Converters: Response to a Step Change in Freestream Temperature as related to Controlling Automobile Emissions," Ind. Eng. Chem. Prod. Res.Dev., 21, p. 29, 1982. 2. S. Siemund, P. Leclerc, D. J. Schweich, M. Prigent and F. Castagna, "Three-way Monolithic Converters: Simulations versus Experiments," Chemical Engineering Science, Vol. 51, N0. 15, pp. 3709-3720, 1996. 3. Subramanian, B. and Varma, A., "Reactions of CO, NO, O2, and H2O on Three-way and Pt/AL2O3 Catalyst," Frontiers in Chemical Engineering Proceedings of the International Chemical Engineering Conference, Vol.1, pp. 231-240. 1984. 4. Subramanian, B. and Varma, A., "Reaction Kinetics on a Commercial Three-way Catalyst: the CO-NOO2-H2O System," Ind. Engng Chem., Prod. Res. Dec. 24, pp. 512-516, 1985. 5. Koltsakis, G. C., Konstantinidis, P. A. and Stamatelos, A. M., "Development and Application Range of Mathematical Models for 3-way Catalytic Converters," Applied Catalysis B: Environmental, Vol, 12, No. 2-3, pp. 161-191, 1997. 6. Voltz, S. E., Morgan, C. R., Liederman, D. and Jacob, S. M., “Kinetic Study of Carbon Monoxide and Propylene Oxidation on Platinum Catalysts,” Ind. Engng Chem. Prod. Res. Dev. 12, p. 294, 1973. 7. Otto, N. C. and LeGray W. J., “Mathematical Models for Catalytic Converter Performance,” SAE paper No. 800841, 1980. 8. Montreuil, C. N., Williams, S. C., and Adamczyk, A. A., “Modeling Current Generation Catalytic Converters: Laboratory Experiments and Kinetic Parameter Optimization – Steady State Kinetics,” SAE paper No. 920096, 1992. 9. Shen, H., Shamim, T., Sengupta, S., Son, S. and Adamczyk, A., "Performance Simulations of Catalytic Converters during the Federal Test Procedure," Proceedings of the 33rd National Heat Transfer Conference, August 15-17, 1999, Albuquerque, New Mexico. 10. Chen, D. K., Oh, S. H., Bisselt, E. J. and Van Ostrom, D. L., "A Three-dimensional Model for the Analysis of Transient Thermal and Conversion Characteristics of Monolithic Catalytic Converters," SAE paper 880282, 1988. 11. Gandhi, H. S., Delosh, R. G., Piken, A. G. and Shelef, M., “Laboratory Evaluation of Three-way Catalysts,” SAE Transactions, Sec.2, Vol.85, 1976, p. 201. NOMENCLATURE Cg j = gas phase concentration, moles/M3 Csj = surface concentration, moles/M3 Cpg = specific heat of gas, J/kg*K Cps = specific heat of substrate, J/kg*K EA, E = activation energy, Pa-m3/g-mole 9 Ga = geometric surface to volume ratio, M2/M3 ∆Hj = heat of reaction j, J/mole hg = heat transfer coefficient between flow and substrate, J/M2*s*K h∞ = heat transfer coefficient between substrate and atmosphere, J/M2*s*K kmj = mass transfer coefficient for species j, M/s QR = reaction heat, J/mol Rj = reaction rate of jth reaction, mole/M3*s Sext = external surface to volume area ratio, M2/M3 t = time, s T∞ = ambient temperature, K Tg = gas temperature, K Ts = substrate temperature, K Vg = gas flow velocity, m/s Xsi = mole fraction of species i in substrate z = axial coordinate, m α = hydrogen-to-carbon ratio in the fuel ε = void volume fraction λs = thermal conductivity of substrate, J/M*s*K ρg = gas density, kg/M3 ρs = substrate density, kg/M3