December 2013/January 2014 / Issue 4

advertisement

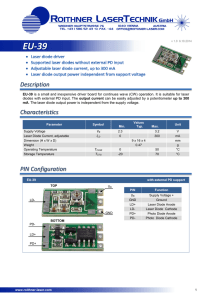

Customer Support Newsletter SERVICE SUPPORT SATISFACTION Customer First December 2013/January 2014 Issue 4 Recording an Autopilot Issue Using the DTS Tester The DTS tester can aid in troubleshooting issues with the autopilot on the EC135, which may save you time and money. One feature of this test equipment is its ability to record either an inflight issue or a preflight test issue. When a recording is performed, the recorded event can be viewed by the technician onsite, by technical support via email or by factory engineering support. The technician and local Airbus Helicopters, Inc. (AHI) Technical Support can only view the page of the DTS that was selected during the recording. However, Airbus Helicopters Deutschland (AHD) can view all parameters of the entire flight. It is important to make the recordings as small as possible so they can be sent via email. If a file is too large for email, it can be placed on an external memory device and mailed. If you have any questions on this procedure, please contact AHI Avionics Tech Support. Perform a recording using the DTS Tester When starting the DTS program, a Windows page will pop up giving the location where the recording will be stored. Ensure the title and locations are written down. After this is done, click OK. Next you will need to scroll to the page to be recorded. When the page to be recorded is displayed and you are ready to record, click on the “Green” button at the top of the window. 1 When this button is pushed and the DTS is recording, the “Green” button will turn “Red”. To stop recording, click on the “Red” button. When the recording is stopped, it will turn “Green” again. After the recording has been completed, the file can be accessed in the location that was written down on the 1st page. Each time a recording is performed, a .DAT file and Text document are created. The Text document contains all the information about the recording. 2 These files can be emailed for viewing. You would need to send both the .DAT file and the Text document that goes with it. If you would like to replay the recording click on Buffers, go down to Data Source and select file. You will hit the browse button and go to the storage location of the .DAT file and double click on the .DAT file to be played. When the DAT is loaded, scroll to the page that was recorded and hit the play button. This will replay the recording. 3 How to Check a Diode with a Digital Multi-meter Diodes are semiconductor devices that conduct current in one direction only, and are commonly made from silicon or germanium. Diodes have two terminals -- an anode and a cathode -- with the cathode being marked by a line painted on the body of the diode. Current is allowed to flow from the anode to the cathode, but is blocked in the other direction. This property is used most commonly in rectifier circuits, which change alternating current to direct current. Diodes are also used to protect components in a circuit if the power is connected the wrong way, blocking the flow of current to prevent damage. Although diodes rarely fail, it can happen if they are exposed to voltage or current above their rated limits. Below is how to check a diode with a digital multi-meter. Step 1. Set the multi-meter to its diode test mode, denoted by the circuit symbol for a diode, which looks similar to an arrow. If the multi-meter does not have a diode mode, set it to the lower end of the resistance range. Step 2. Connect the multi-meter positive lead to the anode and the negative lead to the cathode. (In order for the test to be accurate, disconnect the power and one end of the diode before testing.) As long as you have correctly identified the anode and cathode, this connection should forward bias the diode, resulting in low to zero resistance as measured on the multi-meter. (0.500-0.60 Step 3. Reverse the leads. Attach the negative lead to the anode, and the positive lead to the cathode. If the diode is working properly, and you have correctly identified the leads, this should reverse bias the diode, resulting in a high resistance measurement. (OL) Interpret the results. If you get an open circuit in one direction indicating the current is blocked and a low resistance reading in the other direction, the diode functions properly. If there is an open circuit in both directions, the diode has failed with an open circuit. If there is a low resistance in both directions, the diode has failed with a short. In both cases the diode should be replaced. 4 SAGEM AHRU Customer Removal Report Airbus Helicopters, Inc. (AHI) would like to introduce you to the SAGEM Customer Removal Report. This report will be shipped with every Attitude Heading Reference Unit (AHRS) in order to collect data on removals and reasons for failure. We kindly ask that any time an AHRU is removed due to malfunction, as much information as possible is provided in the form. This data will greatly assist SAGEM in reliability and root cause analysis. If at any time you need a copy of this form, you may download it with this link or contact your AHI Technical Representative and one will be provided to you. <<<<Click Here for Form>>>> Did You Know? Tail rotor blades, p/n 355A12-0055-00/01/02/03 and p/n 355A12-0060-00/01, used on the AS350B3e originally came with pitch horn, p/n 355A12-5102-00, having a 1,000-hour life. Upon reaching this life limit, the pitch horns are being replaced with p/n 355A12-5102-01 having a 20,000-hour life. All previous pitch horns had a 10 mm hole that fit onto the dowel pin on the blade. The new pitch horns have an 8 mm hole in them, requiring new part number dowel pins 355A12-5107-20 that are stepped down to 8 mm so as to fit into the new pitch horns. So, when you order your new pitch horn, be sure to order the new dowel pins, as well. 5 Keycopter: Feature of the Month Keycopter has new “Ship Complete, Cancel Line Demand, Cancel Order Demand, and Logout Features”. Check Them Out!! Keycopter now gives you the ability to request Ship Complete, Cancel Line Demand, and Cancel Order Demand and to Logout of the portal. Ship Complete Step 1:Access the E-Spares < E-Ordering menu Step 2:Select the “Create a new shopping cart” tab to begin order creation Step 3:Select the “Ship Complete” checkbox to have all parts on that order shipped at once, which will reduce the shipping cost. 6 Keycopter: Feature of the Month (cont’d) Cancel Line Demand & Cancel Order Demand Step 1:Access the E-Spares < E-Ordering menu Step 2:Select the “Tracking” tab to search a previously placed order by Your Reference, Eurocopter Transaction Reference, Delivered Part Reference, NATO Code, or Eurocopter Delivery Number. Step 3:Once the order has been accessed, select the Cancel Line Demand if there are certain line items that need to be canceled. Select the Cancel Order Demand if the entire order needs to be canceled. This will automatically send a request to the Spares department. Logout Button The “Logout” button is now available on Keycopter. It provides the ability to exit the portal to prevent the system from timing out. 7