Instruction Sheet

408-3144

NETCONNECT* Undercarpet Power Cabling

System Power Whip Kit 554181

NOTE

29 JUN 07

Rev B

Dimensions are in metric units [followed by U.S.

customary units in brackets].

i

To obtain information on AMP NETCONNECT products, call

PRODUCT INFORMATION at the number at the bottom of

this page, or visit the AMP NETCONNECT website at

Reasons for reissue are provided in Section 5,

REVISION SUMMARY.

www.ampnetconnect.com

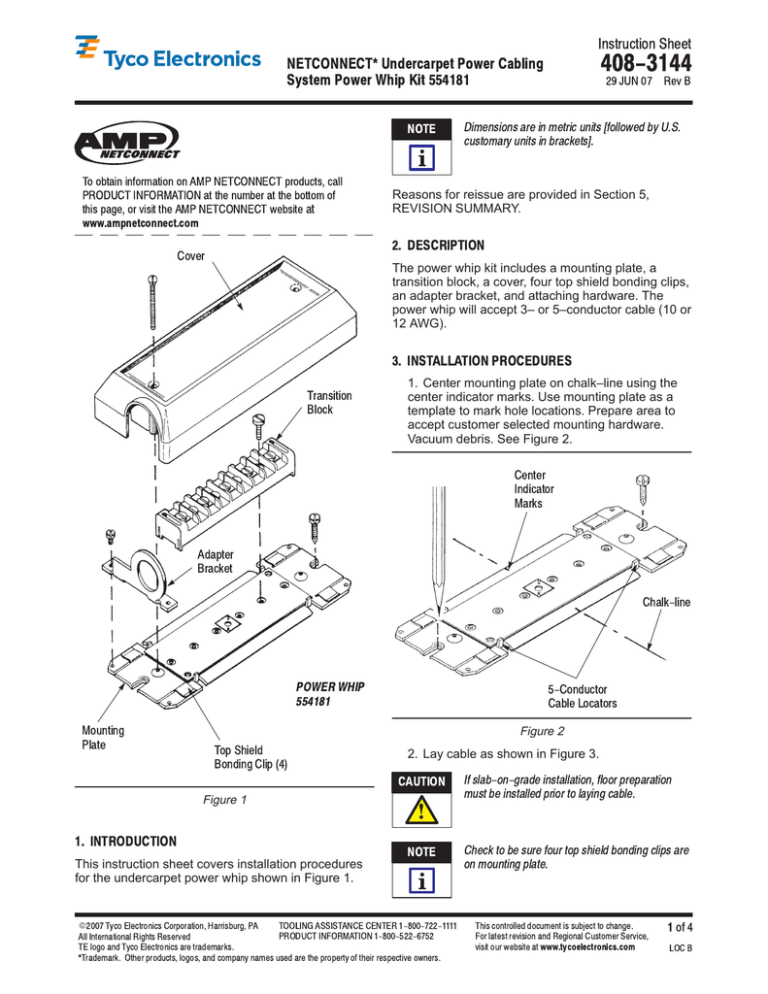

2. DESCRIPTION

Cover

The power whip kit includes a mounting plate, a

transition block, a cover, four top shield bonding clips,

an adapter bracket, and attaching hardware. The

power whip will accept 3– or 5–conductor cable (10 or

12 AWG).

3. INSTALLATION PROCEDURES

Transition

Block

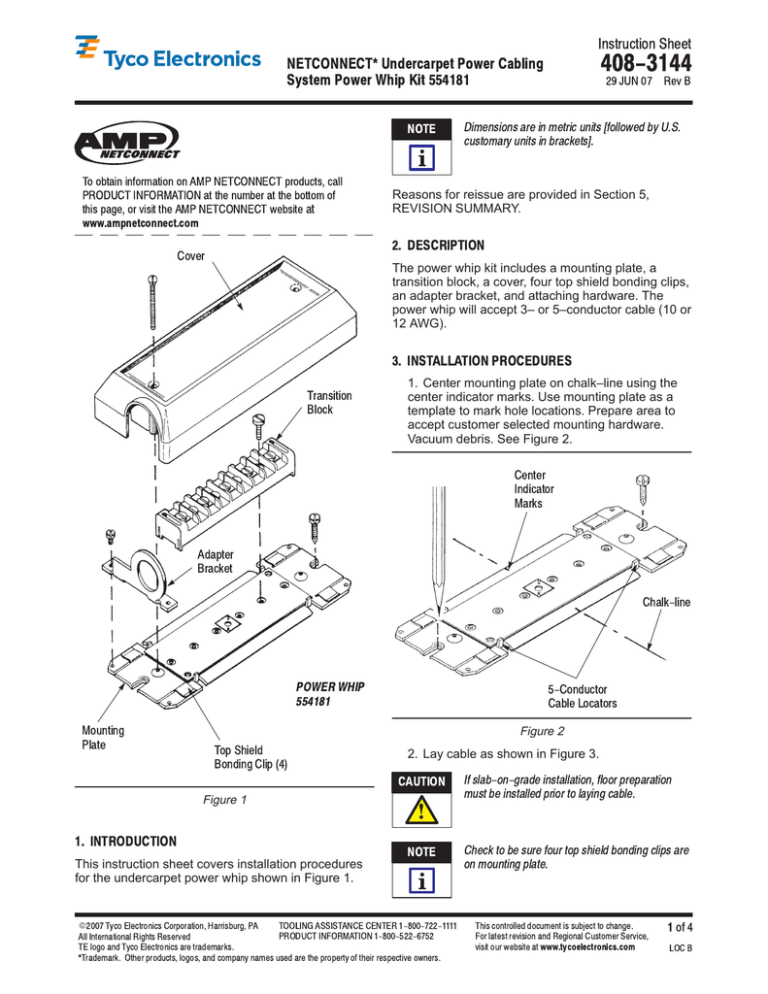

1. Center mounting plate on chalk–line using the

center indicator marks. Use mounting plate as a

template to mark hole locations. Prepare area to

accept customer selected mounting hardware.

Vacuum debris. See Figure 2.

Center

Indicator

Marks

Adapter

Bracket

Chalk-line

POWER WHIP

554181

5-Conductor

Cable Locators

Figure 2

Mounting

Plate

Top Shield

2. Lay cable as shown in Figure 3.

Bonding Clip (4)

CAUTION

must be installed prior to laying cable.

Figure 1

!

1. INTRODUCTION

NOTE

This instruction sheet covers installation procedures

for the undercarpet power whip shown in Figure 1.

E

2007 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

If slab-on-grade installation, floor preparation

Check to be sure four top shield bonding clips are

on mounting plate.

i

TOOLING ASSISTANCE CENTER 1-800-722-1111

This controlled document is subject to change.

PRODUCT INFORMATION 1-800-522-6752

For latest revision and Regional Customer Service,

TE logo and Tyco Electronics are trademarks.

*Trademark. Other products, logos, and company names used are the property of their respective owners.

visit our website at www.tycoelectronics.com

1 of 4

LOC B

408-3144

Power Whip Kit

7. Tape top metal shield to floor.

8. Mount transition block over cable, making sure

that the silver–headed screw is in the neutral

conductor and the green–headed screw is in

alignment with the green conductor on the flat

power cable. Place four screws into position. Place

screwdriver on each screw and tap with hand to

punch screw through cable. Screws should be

tightened alternately from center positions to

outside until all screws are tightened to 88.96

newtons [20–in. pounds]. See Figure 5.

Upper Vinyl

Shield

Top Shield

Clip (Typ)

NOTE

For dead-end application, cable should be cut

square about 6.4 mm [.25 in.] from end of

i

mounting plate. Slide bottom vinyl shield under

mounting plate and fold upper vinyl shield back.

Observe polarity and insert end of cable into slot

on side of transition block. Slide cable along slot

until properly positioned according to cable size.

Upper Vinyl

Install top metal shield and transition block on

Shield Cut Line

mounting plate as previously described. See

Figure 6.

Figure 3

Assembly Screw (Typ)

Green-Headed

3. Slide mounting plate between bottom vinyl

shield and cable. Secure mounting plate to floor.

4. Cut upper vinyl shield in the center of the

mounting plate.

Screw (Ground)

Terminal

Screw

(Typ)

Silver-Headed

Screw (Neutral)

Terminal

5. Lay top metal shield. Mark top shield at cut line

indicator and cut top shield. Slide top shield under

top shield bonding clips. See Figure 4.

(Typ)

Top Shield

Metal

Top Shield

Clips

Figure 5

Tape

(Typ)

Upper Vinyl Shield

Top Shield Cut

Folded Back and

Line Indicator

Taped

Option

Run cable 25.4mm [1 in.] past transition block

and insulate end with insulator or electrical tape.

i

(Typ)

9. Mount bracket on mounting plate and install

flexible conduit to bracket. See Figure 7.

Figure 4

6. Fold upper vinyl shield back over top metal

shield and tape in place.

2 of 4

10. Observe polarity and connect wires to

transition block.

Tyco Electronics Corporation

Rev

B

408-3144

Power Whip Kit

4. REMOVING POWER WHIP (Figure 9)

5-Conductor

Cable Position

DANGER

To avoid injury, disconnect electrical power before

beginning work on any circuit.

3-Conductor

Cable

1. Remove screws securing cover to mounting

plate and remove cover.

Cable Position

Stop

2. Disconnect the electrical connectors from the

transition block and remove the flexible conduit

connector from the adapter bracket.

Slide Cable

into Slot

3. Remove the four assembly screws securing the

transition block to the mounting plate.

Cover

Figure 6

Bracket

Figure 8

4. Remove tape from top shield within 0.6 to 0.9m

[2 to 3 ft] of mounting plate and slide top shield out

of top shield bonding clips.

Flexible

Conduit

Flexible Conduit Connector

Figure 7

5. Remove hardware securing mounting plate and

slide mounting plate from between cable and

bottom vinyl shield.

6. Lay top shield and top vinyl shield back away

from installation.

7. Install insulating patches per instructions

packaged with patches.

NOTE

It is recommended that customer supplied

terminals be installed on the end of the

i

conductors when using 10 or 12 AWG stranded

wiring installed under the terminal block screws.

11. Place cover over transition block and secure

it to mounting plate with screws provided. See

Figure 8.

Rev

B

8. Trim top shield and top vinyl shield to lie outside

of patch. Install a section of top metal shield across

the opening and secure to original top shield with

spring clips 553534–1.

NOTE

A transition block that is used on a 3-conductor

cable should not be reused on a 5-conductor

i

Tyco Electronics Corporation

application.

3 of 4

408-3144

Power Whip Kit

Figure 9

5. REVISION SUMMARY

Since the previous release of this document, the

format has been updated to the current corporate

requirements.

4 of 4

Tyco Electronics Corporation

Rev B