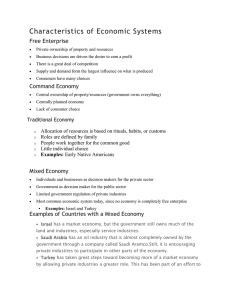

Document

advertisement

Fall 2013

Saudi Aramco

A quarterly publication of the Saudi Arabian Oil Company

Integrated Technologies Yield Five Years of Excellent Performance:

A Unique Field Case Study

see page 2

First Successful Application of Limited Entry Multistage Matrix Acidizing in

Saudi Aramco’s Deep Gas Development Program: A Case Study for Improved

Acid Stimulation and Placement Techniques

see page 21

Journal of Technology

THE SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Saudi Aramco

Fall 2013

A quarterly publication of the Saudi Arabian Oil Company

Contents

Integrated Technologies Yield Five Years of Excellent

Performance: A Unique Field Case Study

2

Orji O. Ukaegbu and Essam M. Al-Alyan

Development of an Automated Environmental

Monitoring System for Groundwater

7

Philip E. Reed and Daniel W. Beard

Innovative Process to Ensure Efficient Multistage

Fracturing Treatments

13

Ibrahim M. Hakami, Francisco A. Gomez, Khalid S. Asiri, Wassim

Kharrat, Fernando Baez, Eduardo Vejarano R. and Danish Ahmed

First Successful Application of Limited Entry Multistage

Matrix Acidizing in Saudi Aramco’s Deep Gas Development

Program: A Case Study for Improved Acid Stimulation and

21

Placement Techniques

Mahbub S. Ahmed, Dr. Zillur Rahim, Ali H. Habbtar, Dr. Hamoud A.

Al-Anazi, Adnan A. Al-Kanaan and Wael El-Mofty

Upgrading Multistage Fracturing Strategies Drives Double

Success after Success in the Unusual Saudi Gas Reserves 29

Mohammed A. Al-Ghazal, Saad M. Al-Driweesh and

Fadel A. Al-Ghurairi

Illuminating the Reservoir: Magnetic NanoMappers

40

Abdullah A. Al-Shehri, Dr. Erika S. Ellis, Jesus M. Felix Servin,

Dr. Dmitry V. Kosynkin, Dr. Mazen Y. Kanj and Dr. Howard K.

Schmidt

Field Evaluation of LWD Resistivity Logs in Highly

Deviated and Horizontal Wells in Saudi Arabia

48

Dr. Pedro Anguiano-Rojas, Douglas J. Seifert, Dr. Michael Bittar,

Dr. Sami Eyuboglu, Dr. Yumei Tang and Dr. Burkay Donderici

Integrated Geology, Sedimentology and Petrophysics

Application Technology for Multimodal Carbonate

Reservoirs

55

Roger R. Sung, Dr. Edward A. Clerke and Dr. Johannes J. Buiting

Integration of Static and Dynamic Data for Enhanced

Reservoir Characterization, Geological Modeling and Well

62

Performance Studies

Dr. Shouxiang M. Ma, Dr. Murat M. Zeybek and Dr. Fikri J. Kuchuk

Solid Particle Erosion in a Partially Closed Ball Control

Valve

Dr. Ehab Elsaadawy, Dr. Marcello Papini and Dr. Abdelmounam M.

Al-Sherik

70

Journal of Technology

THE SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Integrated Technologies Yield Five Years

of Excellent Performance: A Unique Field

Case Study

Authors: Orji O. Ukaegbu and Essam M. Al-Alyan

ABSTRACT

This article covers the story of a field that was brought on

production using a combination of industry leading edge technologies: maximum reservoir contact (MRC) multilateral

wells, advanced well completions and intelligent field infrastructure. Though individual components of the technologies

had been tested and proven, the combination of these technologies

in one development made this field stand out as a first in the

industry. This feat came with particular challenges and rewarding opportunities.

This article undertakes an assessment of the field, the wells

and the technologies, following five years of production, in a

unique case study detailing real-time field and well performance

monitoring, management and production optimization. The

experience from this field has provided unique knowledge and

insight to better understand how the advantages of these technologies were leveraged to take performance to the next level.

During the five years of production, this field has met or exceeded the fundamental field key performance indices (KPIs),

such as production targets, sweep efficiency and well potential.

Moreover, the intelligent field infrastructure environment has

made possible proactive real-time reservoir management, leading to more efficient operations and results oriented business

workflows.

INTRODUCTION

Haradh is the southernmost production area in the super giant

field Ghawar. The Arab-D reservoir focused on in this article

produces Arabian Light crude oil. Haradh was developed in

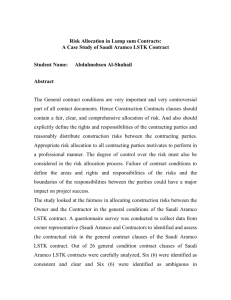

three increments, Fig. 1, over a span of 10 years, and Haradh-III

is the last of the three increments to be developed. While most

parts of Ghawar were developed predominantly with vertical

wells decades ago, before recent advances in drilling and completion technology, the challenge in the Haradh-III development

was to leverage recent technology advancements1 to achieve

significant savings in development and operating costs per

barrel, with long-term sustenance of well productivity and

maximization of oil recovery.

The advances in technology presented development alternatives and ample opportunity to add value by building on

2

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Fig. 1. Map of Ghawar showing Haradh increments.

lessons learned from previous developments. The Haradh

increments were brought on production at 300 thousand barrels

of oil per day (MBOPD) each, but were developed with different

technologies. Haradh-I was developed in 1996 primarily with

vertical wells, and Haradh-II was developed in 2003 using single

lateral horizontal wells2. Haradh-III was developed in 2006

using a combination of industry leading edge technologies to

create the world’s largest field development with maximum

reservoir contact (MRC) multilateral wells, advanced well

completions and intelligent field infrastructure. Though individual components of the technologies had been tested and

proven, the combination of these technologies in one development made Haradh-III stand out as a first in the industry. This

feat came with particular challenges3, 4 and rewarding opportunities.

One of the main technology decisions for the Haradh-III

development was replacing many single lateral horizontal wells

with only 32 MRC multilateral wells to deliver 300 MBOPD

with substantial capital costs (CAPEX) avoidance. The initial

concerns were whether drilling technology1 had matured sufficiently to deliver the MRCs to plan; whether 32 MRCs were

sufficient to deliver the target production of 300 MBOPD

sustainably; and whether a huge price would be paid for the

advanced completions that might prevent future access to the

reservoir should frequent well intervention and workovers

become necessary to achieve project objectives.

After five years of continuous, uninterrupted production, the

pre-development concerns have been put to rest. The historical

data to date are being utilized to benchmark and evaluate the

performance of the various technologies deployed in the

Haradh-III development against project objectives and expectations set prior to field development and to assess their impact

on fluid behavior and sweep.

This article undertakes an assessment of the impact of the

various technologies deployed in Haradh-III in three broad categories — field and well performance; production optimization;

and real-time reservoir management — in relation to initial

concerns and expectations, and in comparison with Haradh-I

and Haradh-II, which were developed without these technologies.

TECHNOLOGIES DEPLOYED IN HARADH-III

DEVELOPMENT

It is not the intention of this article to delve into the operational

details of the deployment of the technologies and strategies

adopted in the development of Haradh-III, as numerous published SPE papers and journals have covered the subject. Suffice

it to say that the main focus of this article is on an evaluation

of the impact of MRC multilateral wells, advanced well completions (AWCs) and intelligent field infrastructure on overall

field performance. The AWC implemented in Haradh-III consists

of remotely operated chokes and inflow control valves (ICVs),

emergency shutdown systems and permanent downhole monitoring systems (PDHMSs), along with surface multiphase flow

meters (MPFMs).

The Haradh-III wells were completed with up-to-date

downhole and surface production technologies to control and

monitor well performance and optimize production and reservoir performance. Each oil well is connected to a MPFM,

allowing selective control and measurement of production rate

and phase fraction at various choke settings, including high

accuracy pressure and temperature measurements. The MPFM

is connected to the remote terminal unit (RTU), which collects

all well data and transmits them to the supervisory control and

data acquisition system (SCADA)5. All these technologies are

linked by the fiber optic based open transport network (OTN)

data communication system. The OTN together with the

SCADA, RTU, MPFM and AWC make up the intelligent field

infrastructure, which provides real-time data acquisition and

monitoring for quick decision making. Measurements of pressure and temperature, and oil, gas and water rates are carried

out in real time and transmitted to the data center and desktops

for prudent reservoir management and active reservoir surveillance to optimize reservoir performance.

required, thereby meeting one of the key performance indicators

(KPIs) and goals of the project. MRC multilateral wells have

been a major game changer, enabling Haradh-III to meet or

exceed project expectations. Trilateral and quad-lateral MRCs

deployed in Haradh-III have produced significant productivity

gains over single lateral horizontal wells, with savings in initial

development costs6. The large footprint of the MRCs has delivered higher productivity and an enlarged drainage area per

well, and target oil production rates have been sustained at

lower drawdown7.

Figure 2 compares the average sustainable rate per well of

Haradh-III with those of Haradh-I and Haradh-II. The average

sustainable rate per well in Haradh-III is five times the rate in

Haradh-I and more than twice the average sustainable rate in

Haradh-II. In addition to the productivity gains, the decline

rates observed in Haradh-III wells have been less than expected,

resulting in savings from drilling of maintain-potential wells.

Previous studies in Haradh-I and Haradh-II have shown that

reservoir heterogeneities, such as fractures, vugs and superpermeability stratiform, play a significant role in the fluid displacement process8, 9, and these perhaps were responsible for

water arrival in a few wells. This experience has been mitigated in Haradh-III due to the positive impact of the MRCs,

attributable to not only their large footprint but also the architectural design of the MRCs. The MRC wells operate at lower

drawdown to allow sweep and recovery by matrix dominated

by gravity displacement10, 11. In addition, the design of the

MRC1 allowed placement and cementing of the 7” liner section

inside the Arab-D reservoir, which perhaps isolated possible

fracture swarms and super-permeability streaks, thereby contributing to a more uniform sweep.

On all counts of well and reservoir performance indicators,

such as well productivity index (PI), well potential, field water

cut, the number of inactive producers and the number of wells

that experienced water breakthrough, Haradh-III has outperformed Haradh-I and Haradh-II at comparable periods in their

production life. To put this in perspective, Fig. 3 shows a comparison of Haradh-I, II and III in terms of the number of dead

wells (nonactive oil producers) after the first five years of production. So far there have been no dead wells in Haradh-III.

Haradh-I showed the greatest number of dead wells during its

first five years of production, primarily due to its development

IMPROVED FIELD AND WELL PERFORMANCE

Haradh-III was put on production during the first quarter of

2006 at an oil production rate of 300 MBOPD. Since coming

onstream, production has been sustained at target rates as

Fig. 2. Sustainable well rate after the first five years of production (MBD).

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

3

Fig. 3. Number of dead wells after the first five years of production.

Fig. 5. Well optimization result (MBD), HRDH-A01.

Fig. 4. Field water cut after the first five years of production.

Fig. 6. Well optimization result (MBD), HRDH-A05.

with vertical wells with full bore penetration of all stratigraphic

zones, which consequently suffered early arrival of water12 in a

bottoms-up sweep pattern.

Figure 4 shows the average field water cut per increment after

the first five years of production. After five years of production,

Haradh-III is showing traces of water. During a comparable

period in the production life of Haradh-I and Haradh-II, they

showed three to four times the level of water compared to

Haradh-III. Given the similarities in rock quality and fluid

displacement mechanism among the three increments, the outperforming by Haradh-III in terms of the number of dead wells

and water cut behavior is attributed to the novel technologies

deployed in developing Haradh-III and the new business environment made possible by new technologies.

PRODUCTION OPTIMIZATION

To fully realize the benefits of a higher PI at a lower drawdown

made possible by the larger footprint of the MRCs, an AWC

was necessary to ensure that all laterals were contributing to

fluid flow into the wellbore and that cross flow was minimized. Downhole ICVs were installed in individual laterals of

the MRCs to control production and balance withdrawal from

individual laterals. This enabled the MRCs to achieve desired

withdrawals at lower drawdown in an environment of controlled

flood front advancement and consequently to minimize water

cut10, 13, 14.

AWCs have continued to be instrumental in the exercising of

prudent reservoir management controls on individual laterals

to optimize production and maximize well value. Production

4

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

optimization is now a routine reservoir management task, utilizing capabilities presented by the remote control of individual

laterals and real-time capture and measurement of production

rates and phase fractions from desktops. Recent examples of

well optimization efforts are shown in Figs. 5 and 6 on MRC

producers HRDH-A01 and HRDH-A05.

In both examples, the individual laterals were tested

through different downhole choke settings at a constant surface choke setting while recording measurements of oil and

water rates and bottom-hole pressures in real time. Thereafter,

an optimized choke setting was selected, resulting in substantial

oil gains and the reduction or elimination of water production.

In MRC HRDH-A01, after the optimization, the oil rate increased by 40% and water production was reduced to zero. In

MRC HRDH-A05, the post-optimization oil rate was 50%

higher and water production dropped by 50%.

REAL-TIME RESERVOIR MANAGEMENT

As part of the novel technologies implemented in Haradh-III,

every producer is connected to a MPFM, allowing selective

control and measurement of production rate and phase fraction

at various choke settings, including high accuracy pressure and

temperature measurements. The MPFM is connected through

the RTU to the SCADA. Integration of MPFMs into the intelligent field infrastructure has enabled accurate measurement of

production rates and proper production allocation for every

well, which is essential for proper reserves accounting and

prudent reservoir management.

The intelligent field infrastructure has enabled Haradh-III to

have a full-fledged capability of remote well control and monitoring. The ability to remotely open, close and control wells

through surface and subsurface sensors and to capture reservoir

performance information in real time has opened limitless opportunities for proactive and real-time reservoir management15.

The benefits have been multifaceted, from less human intensive

well interventions, to capturing and using real-time data from

wells and surface facilities for making timely production and

reservoir management decisions. The remotely operated chokes

and valves have made it possible to adjust well rates or shut-in

wells without the need for field support.

The Haradh increments are produced under pressure maintenance by peripheral water injection. The real-time measurement

and monitoring of rates and reservoir pressure has enabled

quick and timely adjustment of production and injection rates

as necessary to achieve the desired injection production ratio

in line with reservoir management strategy, all without the

delay attendant on the need to wait for back-allocated production injection data. In addition, pressure measurements from

the PDHMSs of numerous standing observation wells and also

from the PDHMSs of MRCs when they are shut-in on scheduled

maintenance provide continuous and reliable reservoir pressure

for routine monitoring.

The real-time data transmitted to data centers and desktops

have been customized to be displayed as a health check for

reservoir performance16. Real-time display of production and

injection rates by well and by reservoir — and also the display

of critical operational indices of the reservoir, such as total

number of active wells, shut-in wells, overproducing or overinjecting wells (compared to target), and underproducing or

under-injecting wells — has helped to track changes in reservoir

performance with time and ensure compliance of field operations

to set production priorities and injection production strategy.

Real-time capture of information combined with proactive

reservoir management has led to savings in operating costs and

the potential to lengthen the production plateau.

CONCLUSIONS

The Haradh-III development encompassed a combination of

industry leading edge technologies: MRC multilateral wells,

AWCs and intelligent field infrastructure. The novel technologies

deployed in the Haradh-III development have been costeffective, as evidenced by well and reservoir performance indicators, and have resulted in savings in development and operating

costs. During the five years of production, this field has met or

exceeded the fundamental field KPIs, such as production targets,

sweep efficiency and well productivity. The technologies provided a platform to utilize real-time capture of information for

prudent reservoir management controls on individual laterals

and wells to optimize production and maximize well value,

with the potential to lengthen the production plateau and

increase oil recovery. The experience from this field has provided

unique knowledge and insight to better understand how the

advantage of these technologies could be leveraged to take

performance to the next level.

ACKNOWLEDGMENTS

The authors would like to thank the management of Saudi

Aramco for their permission to publish this article. The authors

would also like to thank the ‘Udhailiyah Reservoir Management

Division and the Southern Area Reservoir Management

Department for their encouragement and guidance. We also

would like to acknowledge the contributions of many individuals

and peers from Saudi Aramco’s E&P community.

This article was presented at the SPE Saudi Arabia Section

Technical Symposium and Exhibition, al-Khobar, Saudi

Arabia, May 15-18, 2011.

REFERENCES

1. Al-Bani, F., Baim, A.S. and Jacob, S.: “Drilling and

Completing Intelligent Multilateral MRC Wells in Haradh

Inc-3,” SPE/IADC paper 105715, presented at the

SPE/IADC Drilling Conference, Amsterdam, The

Netherlands, February 20-22, 2007.

2. Mubarak, S.M., Pham, T.R., Shamrani, S.S. and Shafiq,

M.: “Using Downhole Control Valves to Sustain Oil

Production from the First Maximum Reservoir Contact,

Multilateral and Smart Well in Ghawar Field: Case Study,”

IPTC paper 11630, presented at the International

Petroleum Technology Conference, Dubai, U.A.E.,

December 4-6, 2007.

3. Nughaimish, F.N., Faraj, O.A., Al-Afaleg, N.I. and AlOtaibi, U.F.: “First Lateral Flow Controlled Maximum

Reservoir Contact (MRC) Well in Saudi Arabia: Drilling

and Completion: Challenges and Achievements: Case

Study,” IADC/SPE paper 87959, presented at the

IADC/SPE Asia Pacific Drilling Technology Conference and

Exhibition, Kuala Lumpur, Malaysia, September 13-15,

2004.

4. Afaleg, N.I., Pham, T.R., Al-Otaibi, U.F., Amos, S.W. and

Sarda, S.: “Design and Deployment of Maximum Reservoir

Contact Wells with Smart Completions in the Development

of a Carbonate Reservoir,” SPE paper 93138, presented at

the SPE Asia Pacific Oil and Gas Conference and

Exhibition, Jakarta, Indonesia, April 5-7, 2005.

5. Al-Arnaout, I.H., Al-Zahrani, R.M. and Jacob, S.: “Smart

Wells Experiences and Best Practices at Haradh IncrementIII, Ghawar Field,” SPE paper 105618, presented at the

SPE Middle East Oil and Gas Show and Conference,

Bahrain, March 11-14, 2007.

6. Saleri, N.G., Al-Kaabi, A.O. and Al-Muallem, A.S.:

“Haradh III: A Milestone for Smart Fields,” Journal of

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

5

Petroleum Technology, Vol. 58, No. 11, November 2006,

pp. 28-33.

7. Salamy, S., Al-Mubarak, S.M., Al-Mubarak, H., AlDawood, N. and Al-Alawi, A.: “Maximum Reservoir

Contact Wells: Six Years of Performance — Lessons

Learned and Best Practices,” SPE paper 118030, presented

at the Abu Dhabi International Petroleum Exhibition and

Conference, Abu Dhabi, U.A.E., November 3-6, 2008.

8. Al-Kaabi, A.O., Al-Afaleg, N.I., Pham, T.R., Al-Muallem,

A.S., Al-Bani, F.A., Hart, R.G., et al.: “Haradh-III:

Industry’s Largest Field Development with Maximum

Reservoir Contact Wells, Smart-Well Completions, and the

iField Concept,” SPE Production & Operations, Vol. 23,

No. 4, November 2008, pp. 444-447.

9. Pham, T.R., Stenger, B.A., Al-Otaibi, U.F., Al-Afaleg, N.I.,

Al-Ali, Z.A. and Sarda, S.: “A Probability Approach to

Development of a Large Carbonate Reservoir with Natural

Fractures and Stratiform Super-Permeabilities,” SPE paper

81433, presented at the Middle East Oil Show, Bahrain,

June 9-12, 2003.

10. Al-Mubarak, S.M., Pham, T.R., Shamrani, S.S. and

Shafiq, M.: “Case Study: The Use of Downhole Control

Valves to Sustain Oil Production from the First Maximum

Reservoir Contact, Multilateral, and Smart Completion

Well in Ghawar Field,” SPE Production & Operations,

Vol. 23, No. 4, November 2008, pp. 427-430.

11. Al-Arnaout, I.H., Al-Buali, M.H., Al-Mubarak, S.M., AlDriweesh, S.M., Zareef, M.A. and Johansen, E.S.:

“Optimizing Production in Maximum Reservoir Contact

Wells with Intelligent Completions and Optical Downhole

Monitoring System,” SPE paper 118033, presented at the

Abu Dhabi International Petroleum Exhibition and

Conference, Abu Dhabi, U.A.E., November 3-6, 2008.

12. Pham, T.R., Al-Otaibi, U.F., Al-Ali, Z.A., Lawrence, P.

and Van Lingen, P.: “Logistic Approach in Using an

Array of Reservoir Simulation and Probabilistic Models

in Developing a Giant Reservoir with Super-Permeability

and Natural Fractures,” SPE paper 77566, presented at

the SPE Annual Technical Conference and Exhibition, San

Antonio, Texas, September 29 - October 2, 2002.

13. Mubarak, S.M., Dawood, N. and Salamy, S.: “Lessons

Learned from 100 Intelligent Wells Equipped with

Multiple Downhole Valves,” SPE paper 126089,

presented at the SPE Saudi Arabia Section Technical

Symposium, al-Khobar, Saudi Arabia, May 9-11, 2009.

14. Al-Mubarak, S.M., Sunbul, A.H., Hembling, D.,

Sukkestad, T. and Jacob, S.: “Improved Performance of

Downhole Active Inflow Control Valves through

Enhanced Design: Case Study,” SPE paper 117634,

presented at the Abu Dhabi International Petroleum

6

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Exhibition and Conference, Abu Dhabi, U.A.E.,

November 3-6, 2008.

15. Al-Mubarak, S.M.: “Real-time Reservoir Management

from Data Acquisition through Implementation: ClosedLoop Approach,” SPE paper 111717, presented at the

Intelligent Energy Conference and Exhibition,

Amsterdam, The Netherlands, February 25-27, 2008.

16. Al-Dhubaib, T.A., Issaka, M.B., Barghouty, M.F., AlMubarak, S.M., Dowais, A.H., Shenqiti, M.S., et al.:

“Saudi Aramco Intelligent Field Development Approach:

Building the Surveillance Layer,” SPE paper 112106,

presented at the Intelligent Energy Conference and

Exhibition, Amsterdam, The Netherlands, February 25-27,

2008.

BIOGRAPHIES

Orji O. Ukaegbu has more than 20

years of diverse petroleum engineering

experience. He is currently a

Petroleum Engineering Specialist in the

Southern Area Reservoir Management

Department. Orji joined Saudi Aramco

in 2003 and has been involved in

management activities in South

numerous reservoir m

Ghawar, including the Haradh-III increment development.

Prior to joining Saudi Aramco, he worked for Shell in

Nigeria and the Netherlands.

Orji received his B.S. degree in Mechanical Engineering

from the University of Nigeria, Nsukka, in 1988.

Essam M. Al-Alyan joined Saudi

Aramco in 2005 as Reservoir Engineer

working in the Reservoir Management

Department. He has worked in

different assignments as a Production

Engineer and Reservoir Engineer,

handling fields of different maturity

complexity. Essa

Essam worked as a Reservoir Engineer for

and complexity

the Haradh-III increment, the world’s largest field

development with advanced well completions and

intelligent field infrastructure. Currently, he is working

with the Haradh-I increment, one of the most challenging

areas in the super giant field Ghawar.

Essam received his B.S. degree in Petroleum Engineering

from King Saud University, Riyadh, Saudi Arabia.

Development of an Automated

Environmental Monitoring System for

Groundwater

Authors: Philip E. Reed and Daniel W. Beard

ABSTRACT

INTRODUCTION AND BACKGROUND

Protection of groundwater resources in Saudi Arabia is of vital

importance as the Kingdom’s aquifers supply over 90% of the

water used in the country, and are essentially nonrenewable due

to the arid climate, and if impacted, can pose risks to human

health and the environment. As part of its corporate-wide

groundwater protection program, Saudi Aramco actively monitors shallow groundwater at many of its operating facilities,

primarily through a network of hundreds of groundwater

monitoring wells. Groundwater sampling and laboratory

analysis occurs on a periodic basis each year to monitor

changes in groundwater quality. Limited staff and laboratory

resources posed challenges in meeting this objective, and a

practical solution was required.

This article presents a solution to these challenges: the development of an automated, stand-alone measurement system

deployed in groundwater monitoring wells using a multi-parameter sensor array package. A key feature of the package is an

ultraviolet (UV) fluorescence sensor that can measure dissolved-phase aromatic hydrocarbons at microgram per liter

concentrations. In combination with data logging and wireless

capabilities, the deployed system enables real-time and remote

monitoring of groundwater quality from standard 4” diameter

monitoring wells.

Prior to field deployment, a series of laboratory bench-scale

calibration profiles was developed for the UV fluorescence

sensor to determine its sensitivity to typical Saudi Aramco

hydrocarbon streams. A complete prototype system was then

constructed and placed in an active groundwater monitoring

well.

This article discusses the results of the laboratory calibration and field evaluation, including performance monitoring of

individual array components, development of power budgets

to match data logging requirements with solar power generation, data transmission and remote system management via

Ethernet-to-wireless communications, and long-term system

performance in a harsh (high temperature, humid and dusty)

environment. The benefit of this system is that it allows for

automated (and more frequent) monitoring of sensitive and

remote areas, enabling prioritization of staff and laboratory

resources where they are needed the most.

Saudi Aramco’s Groundwater Protection Program incorporates

over 1,000 groundwater monitoring wells, covering nearly 60

operating facilities located throughout the Kingdom of Saudi

Arabia. Groundwater sampling and laboratory analysis must

occur on a periodic basis each year to monitor changes in

groundwater quality and identify any impacts that may pose

risks to human health and the environment. Limited staff and

laboratory resources posed challenges in meeting this objective, and a practical solution was required.

Our solution was to develop an automated monitoring

system incorporating an in situ ultraviolet (UV) fluorescence

sensor that can measure dissolved-phase hydrocarbons at

microgram per liter concentrations. This technology has recently become available and is sensitive enough to measure

volatile organic compounds at the concentration levels necessary to evaluate groundwater impacts. This technology can be

combined with wireless or General Packet Radio Service

(GPRS) capabilities and off-the-shelf data loggers to enable

real-time and remote monitoring of groundwater quality from

monitoring wells.

In the literature, applications of UV fluorescence for measuring hydrocarbons have been published in areas such as online wastewater treatment monitoring and closed-loop cooling

water systems1-4, but not for groundwater monitoring wells.

The intent of developing a groundwater monitoring system using this technology is not to completely replace conventional

groundwater sampling, but to enable early and real-time detection of dissolved-phase hydrocarbons as well as monitoring of

real-time, continuous changes in physical parameters, such as

temperature and water level. The system could also be used as

a tool to measure groundwater remediation progress. Less frequent groundwater sampling can then be instituted to verify

sensor data and to allow for periodic recalibration based on

well specific conditions.

CONCEPT AND SENSOR ARRAY SYSTEM

COMPONENTS

The objectives for developing an automated groundwater

monitoring system were to provide a monitoring platform that

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

7

can operate in a remote or “stand-alone” environment for a

long period of time with minimal servicing, withstand harsh

weather conditions (high operating temperatures, high humidity and dust), be power independent, be sensitive enough to

reliably measure groundwater parameters of interest, including

dissolved-phase hydrocarbons at microgram per liter concentrations, and have the capability to transmit data in real time

from the remote location to the office.

With these objectives in mind, the conceptual design of the

system included the following:

• UV fluorometer capable of detecting dissolved-phase

hydrocarbons in the microgram per liter range.

• Water level sensor with atmospheric pressure

compensation (gauge).

beam is focused approximately 5 nm to 10 nm in front of the

window using a small lens. Emitted light is collected by the

same lens, reflected by the dichroitic beam splitter (due to the

longer wavelengths of the fluoresced light) and detected by a

large area photodiode. An interference filter (center wavelength 360 nm) is used in front of the photodiode to discriminate stray light and to select the fluorescence light.

In addition to using the UV fluorometer to detect hydrocarbons in the monitored groundwater well, other water quality

parameters are measured by the sensor array system, including

atmospheric pressure compensated water level (gauge pressure), groundwater temperature, conductivity and turbidity.

System battery voltage and data logger enclosure temperature

are also recorded.

• Temperature, conductivity and turbidity measurement

instruments.

UV FLUORESCENCE SENSOR CALIBRATION

• Programmable data logger.

The UV fluorescence sensor was factory calibrated by the manufacturer using a proprietary calibration standard. Note that

the amount of aromatic hydrocarbons in a liquid sample can

be determined and related to the total amount of hydrocarbon

present only if the ratio of aromatics to total hydrocarbons remains relatively constant. Should the ratio of aromatics to total hydrocarbons change due to different hydrocarbon product

streams, a new calibration should be established before field

deployment. In this study, the UV fluorescence sensor was recalibrated in the laboratory using typical Saudi Aramco hydrocarbon streams dissolved in water, e.g., using locally produced

laboratory standards of gasoline, diesel and Arab Light (AL)

crude oil.

One unique aqueous calibration standard was prepared for

Saudi Aramco gasoline, diesel and crude oil (three total calibration standards). The calibration standard apparatus was

assembled, and reagent grade water was added to the apparatus

before any hydrocarbon was introduced. The hydrocarbon/water interface layer was never penetrated, agitated, aerated or

disturbed after hydrocarbon was introduced to the apparatus;

however, the aqueous standard was gently mixed to encourage

hydrocarbon partitioning and mixing. Each calibration standard

preparation was allowed to equilibrate for several days prior

to testing. Calibration standards were prepared within sealed

containers to reduce evaporation of the hydrocarbon. Dissolved

phase saturated aqueous fractions were removed from below

the hydrocarbon/water interface to provide approximately

four liters each of the calibration standard for use in the recalibrated hydrocarbon solutions.

For the calibration solutions, the UV fluorescence sensor

was suspended inside a four liter glass beaker together with silicone sample tubing, Fig. 1. The tubing was placed alongside

the sensor window to enable sampling of water as close as

practicable to the sensor. All additions or subtractions of calibration standards and reagent grade water diluents were made

by reversible peristaltic pumps under the solution surfaces. The

calibration solution was stirred gently to mix, but was never

• Solar-charged 12 volt DC battery.

• GPRS or wireless telemetry capability.

The sensor array design included the selection of a miniature

UV fluorometer with dimensions that allowed its deployment

in a 4” diameter groundwater monitoring well. Aromatic hydrocarbons dissolved in water can be stimulated with UV light

to fluoresce. Aromatic compounds in petroleum hydrocarbons

are known to be excited by monochromatic UV light and emit

fluorescent radiation at different wavelengths, according to the

number of aromatic rings present in the compound. Generally,

larger aromatic molecules fluoresce at longer wavelengths. A

relationship results between the aromatic composition of a

petroleum product and the maximum peak fluorescence wavelength. For example, fluorescence from gasoline emits with a

strong single peak at 290 nm, which represents single-ring

mono-aromatics. Fluorescence from diesel emits with its

strongest peak at 320 nm, representing the two-ring di-aromatics.

Peaks at 350 nm, 410 nm and 480 nm represent even larger

aromatic ring compounds. As a result of this relationship, ratios

of fluorescence wavelength peak intensity can distinguish different products. Beer’s Law governs the direct relationship between

the concentrations of the aromatic hydrocarbons in a given

sample (e.g., water) and the amount of UV radiation absorbed

at a specific wavelength. The intensity of the fluorescence

emission is proportional to the concentration of fluorescing

hydrocarbons dissolved in the groundwater.

The sensor used in the array excites the hydrocarbons by activating a miniature 2.5 Hz xenon flash-lamp behind an optical

window. The required wavelength for excitation is selected via

an interference filter centered at 254 nm with a full-width halfmaximum (FWHM) of 25 nm (or 254 nm ± 12.5 nm), detecting

an emission light at 360 nm with a FWHM of 50 nm (360 nm

± 25 nm). A small percentage of the excitation light is reflected

by a dichroitic beam splitter and is used as a reference signal to

evaluate variations of the excitation energy. The excitation

8

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Fig. 1. Laboratory calibration apparatus configuration.

agitated, aerated or disturbed. The sensor and sample tubing

point were placed about 10 cm above the bottom of the

beaker, which was placed over a magnetic stirring plate. Black

nonreflective paper was placed beneath the bottom of the

beaker to reduce reflection errors. Room lighting was switched

off prior to powering up the laboratory instruments to reduce

signal noise effects (controller/data logger and sensor).

The UV fluorescence sensor was connected to a controller/

data logger equipped with a liquid crystal display showing raw

analog output. Calibration solutions were slowly introduced

into the system using the peristaltic pump. Once the sensor

analog output reading stabilized and was recorded, a calibration

solution sample was obtained by reversible peristaltic pump,

filling 125 ml and 40 ml volatile organic analyte (VOA) amber

glass sample bottles. A minimum of one tubing volume was

purged prior to sample collection (providing a sample that

originated as near the sensor detector window as possible).

Additional reagent grade water was added by reversing the

peristaltic pumps, adding and remixing the calibration solution,

and resampling to establish data to prepare calibration graphs

of hydrocarbon concentrations vs. data logger output. Each

time the calibration solution was diluted, and after the data

logger output stabilized and was recorded, the next laboratory

sample was obtained. This process was repeated a total of four

or five times to obtain data points over a sufficient concentration

(output) range to enable reproducible calibration trend line

generation.

Sample bottles were preserved by refrigeration to less than

4 °C and transported to an analytical laboratory for chemical

analyses of total petroleum hydrocarbons (TPH) ranges (C6C9, C10-C14, C15-C28, C29-C36) by USEPA method 80155 and

analyses of volatile organic compounds (VOCs) by USEPA

method 8260. Specifically, the VOA analyses were performed

to evaluate for the presence of benzene, toluene, ethylbenzene

and xylenes (BTEX) in the calibration solutions.

Calibration plots were developed relating UV sensor millivolt (mV) output vs. laboratory determined TPH and BTEX

for each of the calibration solutions evaluated. For the gasoline

calibration solution, the UV fluorescence was very sensitive for

TPH (C6-C9), reaching the upper limit of sensor raw analog

Fig. 2. Gasoline and diesel calibration, TPH.

Fig. 3. AL crude calibration, TPH.

Fig. 4. AL crude calibration, BTEX.

output at TPH concentrations under 200 micrograms per liter

for this carbon range, Fig. 2. Laboratory results for BTEX

compounds were non-detectable at this low TPH range. For

the diesel calibration solution, TPH (C6-C9) response plotted

against sensor mV output produced a fairly linear fit, Fig. 2;

however, the TPH plot (C10-C14) was linear only above a concentration range of about 1,000 to 1,500 micrograms per liter.

The TPH (C10-C14) range may indicate sampling and/or laboratory error or nonlinearity at lower concentrations. Higher

carbon ranges (C15-C28, C29-C36) were below the lower limits

of determination (below 0.1 milligram per liter), and as with

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

9

gasoline, the BTEX constituents were non-detectable at this

low TPH range.

The AL crude solution calibration results, Fig. 3, exhibited

linear responses for TPH (C6-C9), TPH (C10-C14), and TPH

(C15-C28), but TPH (C29-C36) responses were nonlinear.

Separate BTEX constituents were detected and graphed vs.

analog output, Fig. 4.

ARRAY ASSEMBLY AND FIELD DEPLOYMENT

Once the UV fluorometer was calibrated, system components

were assembled into a configuration that allowed for deployment into a 4” diameter groundwater monitoring well. The

monitoring well selected was screened across the water table,

which was present at 1.5 m below ground surface.

Groundwater parameters at the well were recorded with a

calibrated YSI-556 multimeter prior to sensor array deployment and consisted of a temperature of 27 °C, total dissolved

solids content of 19.4 g/l, pH of 7.0, conductivity of 29.8

mS/cm and dissolved oxygen of 0.03 mg/l. The well was located approximately 300 m from the seashore adjacent to a

wastewater evaporation pond. Water levels fluctuated approximately 8 cm per day due to a semi-diurnal tidal influence.

Figure 5 illustrates the system installed at the monitoring

wellhead, including an environmentally sealed fiberglass enclo-

Fig. 5. Sensor wellhead configuration.

Fig. 7. Control box with data logger, RF modem, 12 volt DC battery and keypad.

sure, a 20 watt solar panel and a Yagi-type directional antenna

mounted on a post above ground level. The sensor array, including the UV fluorometer and sensors measuring water level

temperature, conductivity and turbidity, is shown in Fig. 6.

The sensor array was suspended by a length of rope attached

to the wellhead; cables from the sensor package were routed to

the enclosure. Figure 7 shows the inside of the enclosure that

houses the data logger, power supply (12 volt DC battery) and

a 2.4 GHz wireless modem.

Communications with the data logger were by wireless RF

modems. The base station antenna is located on a tall building

2 km away from the field station. A serial device server is used

to interface the RF base station modem to the facility Ethernet.

Com port redirector software is used to create a virtual serial

port connection on a dedicated workstation to collect data

hourly (during daylight hours only) from the field station.

Prior to installation of the sensor package into the monitoring well, a 0.375” internal diameter section of Teflon-lined

polyethylene tubing was affixed to the UV fluorometer with

the end of the tubing located near the optical window. The

tubing was extended up to the top of the well. This provided

the ability for groundwater sampling via a peristaltic pump

connected to the tubing at the surface. The sample tubing end

essentially coincided with the location of the UV fluorometer

instrument window. The UV fluorometer was placed at the

bottom of the array in tandem with the pressure transducer, at

a depth of approximately 2.2 m below the top of the groundwater in the screened section of the monitoring well.

POWER MANAGEMENT AND DATA TRANSMISSION

Fig. 6. Sensor array well package.

10

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Overall system power requirements are very low primarily due

to the selection of components, but also because of the measurement strategy employed with the use of switched sensor

power. The UV fluorescence hydrocarbon sensor has a maximum

Fig. 8. UV fluorometer sensor output, in calibrated TPH.

current drain of ~300 mA while measuring. Other sensors consume approximately 50 mA during measurement. The wireless

modem consumes between 35 mA and 75 mA while communicating with the base station, depending on whether it is transmitting or receiving. It has an average quiescent current drain

of about 4 mA with a half-second cycle, during which it can

respond to a communication attempt from the base station.

To minimize system power requirements, the wireless modem was only powered on during daylight hours. Additionally,

since changes in groundwater well conditions occur slowly,

measurements were made only once hourly for the UV fluorometer and once every 10 minutes for the other water quality

parameters.

Data collected from the field station are written to an ASCII

text file on the workstation. The data from the text files are

automatically read and inserted into a relational database

management system using stored procedures and scheduling.

Excel™ spreadsheets and other applications have been developed to access the data for visualization and reporting purposes. For the UV fluorometer, data was plotted in mVs,

factory calibrated micrograms per liter and calibrated micrograms per liter Saudi Aramco gasoline, diesel and AL crude oil

products. For the remaining sensors in the array, time series

plots were also developed for conductivity, water depth, water

temperature and turbidity. Battery voltage and control panel

temperature readings with time were also plotted to monitor

power draw and environmental conditions.

FIELD PERFORMANCE

The system was allowed to operate with essentially no maintenance to observe its robustness and performance in high temperature, high humidity and dusty conditions. Based on the

data transmitted back to the office desktops, each sensor performed within specifications with the exception of the sidelooking turbidity sensor, which was giving erroneous output

due to the restricted space inside the 4” diameter well.

During the first 21 months of array operation, no detectable

hydrocarbons were noted by the UV fluorometer. At that time,

an increase in sensor output from 400 mV to over 850 mV

Fig. 9. Field sample comparison with TPH calibration.

was noted, Fig. 8. To validate the elevated readings, triplicate

groundwater samples were collected via the tubing using a

peristaltic pump and submitted to an analytical laboratory for

chemical analyses of TPH ranges (C6-C9, C10-C14, C15-C28,

C29-C36) by USEPA 8015 method and analyses of VOCs under

the USEPA 8260 protocols. At the time the samples were collected, the UV fluorometer sensor output was averaging 675

mVs and the TPH results for the C6-C9, C10-C14, C15-C28 and

C29-C36 ranges for the triplicate samples averaged 526 micrograms per liter, 277 micrograms per liter, 2,233 micrograms

per liter and 260 micrograms per liter, respectively. Figure 9

illustrates the comparison of the field samples with the calibration plots for TPH.

After approximately 23 months of sensor array operation, a

degradation of conductivity readings was noted, indicating

that sensor cleaning was required. At this time, the sensor

package was removed from the well to enable observation of

visible signs of corrosion or fouling. The UV fluorometer window was clear with no signs of fouling. The conductivity sensor

was brushed clean and the desiccant for the vented pressure

transducer was also changed. No other serious signs of fouling

or corrosion were noted.

When the measurement scheme was developed, it was expected that accumulated terrestrial dust on the solar panel

might not adequately charge the 12 volt DC battery. This situation has not been the case in over two years of monitoring

with only one intentional rinsing of the solar panel. The system

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

11

battery voltage has not fallen below 12.5 volts during the

entire deployment period.

CONCLUSIONS AND FUTURE APPLICATIONS

As demonstrated in the laboratory calibration and field trials,

aromatic hydrocarbon fluorescence is extremely sensitive to

hydrocarbons in water, and results indicated a linear response

across the concentration ranges tested. The deployed system

continues to perform superbly in the high temperature, high

humidity and dusty conditions prevalent in Eastern Saudi

Arabia. Planned future modifications to the array include

changing the side-looking turbidity sensor with a look-down

type sensor, which has recently become available on the market.

Periodic groundwater sampling from the tubing installed near

the sensors will continue to occur to compare sensor output to

laboratory analytical results.

Future deployment of similarly designed sensors in different

groundwater conditions is planned to observe UV fluorometer

response in differing groundwater chemistries. Other potential

applications include leak detection monitoring where the system can be installed in shallow groundwater conditions near

storage tanks, sumps, piping, etc., in remote areas, and in deep

groundwater conditions.

ACKNOWLEDGMENTS

The authors would like to thank Saudi Aramco management

for their permission to present and publish this article. Special

thanks to Mr. Harry Day, retired Engineering Specialist with

the Environmental Protection Department, for his contribution

during instrument calibration.

A version of this article was presented at the SPE/APPEA

International Conference on Health, Safety, and Environment

in Oil and Gas Exploration and Production, Perth, Australia,

September 11-13, 2012.

REFERENCES

1. Borsdorf, H. and Roland, U.: “In Situ Determination of

Organic Compounds in Liquid Samples Using a Combined

UV-Vis/Fluorescence Submersible Sensor,” International

Journal of Environmental and Analytical Chemistry, Vol.

88, No. 4, April 10, 2008, pp. 279-288.

2. Meidinger, R.F., St. Germain, R.W., Dohotariu, V. and

Gillispie, G.D.: “Fluorescence of Aromatic Hydrocarbons

in Aqueous Solution,” Proceedings of the U.S. EPA/Air and

Waste Management Association International Symposium

on Field Screening Methods for Hazardous Wastes and

Toxic Chemicals, Las Vegas, NV, 1993, pp. 395-403.

3. Tedetti, M., Guigue, C. and Goutx, M.: “Utilization of a

Submersible UV Fluorometer for Monitoring

12

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

Anthropogenic Inputs in the Mediterranean Coastal

Waters,” Marine Pollution Bulletin, Vol. 60, No. 3, March

2010, pp. 350-362.

4. Westaby, C.: “Hydrocarbons in Water Monitoring Using

Fluorescence,” paper presented at the 30th Annual Electric

Utility Chemistry Workshop, University of Illinois at

Urbana-Champaign, June 8-10, 2010.

5. Test Methods for Evaluating Solid Waste, Physical/

Chemical Methods, SW-846, 3rd edition, U.S.

Environmental Protection Agency, Washington, D.C., 2008.

BIOGRAPHIES

Philip E. Reed is an Engineering

Consultant in Saudi Aramco’s

Environmental Engineering Division,

Land & Groundwater Protection Unit.

JJoining Saudi Aramco in 2002, he has

over 30 years of diverse experience in

environmental hydrogeology, including

characterizations, field instrumentation applications,

site characterizations

risk assessments, groundwater remediation design and

construction.

Phil received his B.S. degree in Geology from Rensselaer

Polytechnic Institute, Troy, New York, and his M.S. degree

in Geological and Civil Engineering from the University of

Arizona, Tucson, Arizona.

Phil is also a Registered Professional Engineer in

Arizona and California. He is an active member of the

Society of Petroleum Engineers (SPE) and has previously

been published in the Saudi Aramco Journal of Technology

and other publications.

Daniel W. Beard joined Saudi Aramco

in 2000 as an Environmental Specialist

in the Environmental Protection

Department’s Marine Environmental

Protection Unit. He previously worked

for industry, government, academic

and consulting organizations,

specializing in field sstudies, instrumentation, data automation and processing and database development.

Dan received his B.S. degree in Physical Science with an

emphasis in Atmospheric Science in 1980 from Northern

Arizona University, Flagstaff, AZ, and an M.S. degree in

Physical Oceanography from Texas A&M University,

College Station, TX, in 1984.

Innovative Process to Ensure Efficient

Multistage Fracturing Treatments

Authors: Ibrahim M. Hakami, Francisco A. Gomez, Khalid S. Asiri, Wassim Kharrat, Fernando Baez,

Eduardo Vejarano R. and Danish Ahmed

ABSTRACT

Multistage fracturing (MSF) is a common practice today as it

allows control of the stimulation of long intervals and improves

the ultimate recovery of hydrocarbons. MSF completions,

designed with open hole packers and frac ports, are currently

implemented by Saudi Aramco to control stimulation and improve recovery in gas wells. The integrity of the open hole

packer and the functionality of the frac ports are vital for an

effective fracturing treatment.

During a MSF treatment, the bottom frac port is opened

first by pressurizing the MSF completion to a predetermined

pressure. After the first fracturing stage has been pumped, a

ball is dropped to isolate the lower zone, open the second frac

port with pressure and enable the second fracturing stage. This

step is repeated until all frac ports have been opened and the

corresponding zones have been fraced, one after the other. At

every step of pressurizing the MSF completions, a drop in pressure is automatically interpreted as showing that the correct

frac ports are open and that the MSF completion is ready for

another fracturing stage. The open hole packers are also assumed

to be holding. Opening the wrong frac port or multiple frac

ports at the same time, or having a leaking open hole packer

will certainly lead to undesired results and possible expensive

remedial rig interventions. Therefore, downhole monitoring is

needed to confirm that the MSF completion is ready (i.e., the

correct frac ports are open and the packers are holding) before

every fracturing stage.

The fiber optic enabled coiled tubing (FOECT) system can

be used as a monitoring system by measuring the distributed

temperature survey (DTS), which can be interpreted in real-time

to confirm which frac port is open and if open hole packers are

sealing.

This article demonstrates through two case studies how DTS

was used to assess the readiness of the MSF completion for

proppant fracturing treatment. An innovative profiling process

in the MSF completion is proposed to replace assumptions

with measured facts, to give client confidence on when to start

the fracturing treatment, and to eliminate unnecessary operations by detecting any MSF completion hardware malfunction.

INTRODUCTION

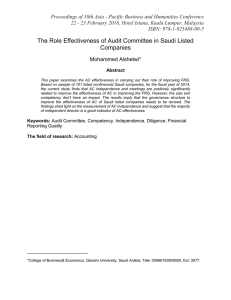

Multistage fracturing (MSF) completions with mechanical

packers were developed in 2001. Since then, it is estimated that

more than 8,000 MSF treatments have been performed worldwide. Saudi Aramco has installed 17 MSF completion systems

since 2007 with the objective of producing gas from its unconventional and tight carbonate and sandstone formations1.

MSF completions are designed to segment the open hole

section into several compartments isolated with mechanical or

swellable open hole packers, Fig. 1, which also make the entire

MSF completion robust and permanent. Frac ports are placed

in between the open hole packers to enable hydraulic fracturing treatments of all compartments, one by one, starting from

the toe. The first frac port at the toe is opened by pressurizing

the MSF completion system to a predetermined value. Drop

ball mechanisms at each of the other frac ports are then activated,

one after the other, to isolate the previously fractured interval

and open the next frac port toward the heel to enable fracturing treatment of the stage. Each dropped ball is slightly bigger

than the previous one. The open hole packers and frac ports

are set according to the open hole log interpretation. The stage

lengths can vary from 200 ft to 1,000 ft. Open hole packers

are also placed without frac ports in between to isolate the

nonproductive zones. After completing all fracturing stages, a

total flow back and cleanup is usually performed.

The fracture geometry generated during a MSF job is affected

by the well azimuth. In fact, longitudinal fractures, Fig. 2a, are

created when the horizontal lateral is drilled toward the maximum stress direction (σH,max), while transverse fractures, Fig.

2b, are created when the horizontal lateral is drilled toward

the minimum stress direction (σH,min). For the latter case, several fractures can be placed one next to the other, as they are

Fig. 1. MSF completion assembly showing open hole packers and frac ports.

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

13

Fig. 2a. Longitudinal fractures, σH,max.

DTS was used in the first MSF completion to confirm that it

was ready for the next fracturing stage and in the second one

to indicate that the well was showing a malfunction of its frac

ports. An innovative FOECT profiling process, based on the

real-time downhole DTS measurements, is proposed to help

the client decide to either proceed with or stop the fracturing

treatment.

TECHNICAL DETAILS

FOECT

Fig. 2b. Transverse fractures, σH,min.

independent of each other. In the former case, however, the

fracture from one interval can grow into the next or previous

zones.

The reservoir contact area increases with the number of

fractures in a MSF completion, which would enable long-term

sustained productivity. But this advantage can be completely

lost should the MSF completion components malfunction. In

fact, below are some scenarios that would call for a workover

rig to recomplete the well:

• The open hole packers fail to seal properly during the

installation of the MSF completion system.

• Multiple or wrong frac ports are open when

pressurizing the MSF completion system.

Below are additional scenarios that would eliminate some

fracturing stages:

• The open hole packers are leaking after an acid

fracturing job.

• One longitudinal fracture is overlapping neighboring

compartments.

The MSF completion is designed without any downhole

check of its components’ performance. It is just assumed that

only the correct frac port is open after pressurizing the completion and that the open hole packers are always sealing properly. Therefore, a downhole monitoring system is needed to

confirm that the MSF completion is holding before every fracturing stage.

A coiled tubing (CT) intervention is needed, first to displace

the wellbore before/after opening the first frac ports, then to

serve as a contingency for the activation or perforation of the

frac ports in the case of malfunction of the drop ball mechanism, acid wash, post-proppant fracturing cleanout, nitrogen

kickoff, and/or the milling of all the dropped balls at the end

of the operation2. The fiber optic enabled coiled tubing

(FOECT) system can improve the efficiency of all the above

interventions, besides the fact that the distributed temperature

survey (DTS) measured with the fiber optic cable will allow

real-time monitoring of the conditions of the frac ports and

open hole packers.

This article demonstrates through two case studies how

14

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

The FOECT is a real-time surface readout system of downhole

measurements. It comprises fiber optic cables installed inside

an Inconel fiber carrier, which is injected inside the CT string,

fiber optic bottom-hole assembly (FOBHA), surface electronics

and software. The FOBHA is capable of measuring in real time

the bottom-hole pressure inside (BHPCT) and outside (BHPAnn)

the downhole tool, the bottom-hole temperature (BHT), casing

collar locator (CCL) and gamma ray (GR) signals, and the

tension-compression (TC) forces at the downhole tool. The

FOECT system allows operators to act with a greater degree of

precision based on real-time interpretation of measured downhole data, eliminating guessing and rule of thumb.

The real-time monitoring and interpretation of the downhole

data acquired from the FOBHA will enable operators to:

• Control the activation of the frac ports based on the

real-time measurement of the TC sub.

• Correlate the depths of the perforations/hydrajetting

slots based on the CCL/GR readings.

• Optimize the post-proppant fracturing cleanout based

on the BHPAnn.

• Optimize the nitrogen kickoff based on the BHPAnn.

DTS

The fiber optic cable acts as a continuous temperature sensor

throughout the length of the CT, which allows the taking of

real-time downhole distributed temperature profiles. The fiber

optic cable is installed in the CT inside an Inconel fiber carrier,

which is non-intrusive, allowing standard operations normally

done with conventional strings to be carried out, including

pumping corrosive fluids and dropping balls. DTS profiles are

recorded from the top of the well to the targeted depth by

sending 10 nanosecond bursts of light down the fiber optic

cable. During the passage of each packet of light, a small

amount is backscattered from molecules in the fiber. This

backscattered light can be analyzed to measure the temperature along the fiber. Because the speed of light is constant, a

spectrum of backscattered light can be generated for each meter of the fiber by the use of time sampling, allowing a continuous log of spectra along the fiber to be generated3.

During the bullheading of neutral fluid through the annulus

Well

Deviation

Tubing

MSF Completions

Frac Port

Open Hole Packer

A

Horizontal

4½” - 12,972 ft

4½” - 15,375 ft

Pressure activated

3½” OD ball

15,318 to 14,720 ft

14,720 to 14,328 ft

B

Slanted 30°

4½” - 12,855 ft

4½” - 14,440 ft

Pressure activated

3” OD ball

3¼” OD ball

3½” OD ball

14,337 to 14,127 ft

14,127 to 13,937 ft

13,937 to 13,817 ft

13,817 to 13,708 ft

Table 1. Data for gas Well-A and Well-B

CT, the temperature profile of the well can be monitored via

DTS. This profile will show some disturbance across the depth

of any open frac ports. In fact, wellbore temperature will decrease up to the injection point. After stopping the injection

and monitoring the warm-back of the wellbore, it can be observed that the profile across any open frac port interval will

take longer to recover heat, which is an indication of fluid intake in that zone. In the case of any failure in the open hole

packers, the temperature profile across will also clearly identify

disturbance in the profile due to flow in the backside. These

real-time downhole measurements will help to confirm if the

correct frac port is open and if the corresponding open hole

packers are sealing, making it safe to proceed with the fracturing stage. The DTS measurement will also provide the reservoir injection profile.

CASE STUDIES

The following case studies provide operational details of the

first implemented FOECT profiling jobs in Saudi Arabia. The

CT intervention objective was to displace the wellbore to brine

and assess the readiness of the MSF completion for fracturing

treatments.

Well Description

The two gas wells, Table 1, were completed with a MSF completion so as to perform segmented proppant fracturing of a

tight sandstone formation.

Job Design

The FOECT run was designed to complete the following steps:

• Run in hole (RIH) to tag the end of the MSF

completion.

• Displace the wellbore to the required brine.

• Pressure up the MSF completion system through CT to

the required pressure to open the first frac ports at the

toe.

• Take DTS-1 profiles while injecting brine through the

annulus CT.

• Take DTS-2 profiles after stopping the injection.

Fig. 3. DTS-1 injection profiles, Well-A.

• Confirm if the first frac port is the only one open and if

its corresponding open hole packers are sealing before

proceeding with the first fracturing stage.

The assessments of the MSF completion before the subsequent

fracturing stages were not approved at this time because the

CT run was not required before the fracturing treatment and

also because the confidence of the service companies in the

performance of their MSF completion was extremely high;

however, CT was available in case of any contingency purpose.

Job Execution — Well-A

After the wellbore was displaced to brine, the MSF completion4 was pressurized for many trials until a drop in pressure

was noticed at a much higher value than the one predetermined to open the pressure activated frac ports (frac port-1).

With the fiber optic cable in position across the first frac port

at the toe, an injection through the annulus CT was initiated

while taking the DTS-1 profiles every 5 minutes, Fig. 3. Then

the DTS-2 profiles were acquired every 20 minutes after stopping the injection to observe the warm-back response of the

wellbore, Fig. 4.

A sharp change in the slope of the DTS-1 profiles can be

observed by examining the sequence of these profiles over

time, Figs. 5 to 8. This change occurred at the depth of the first

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

15

Fig. 4. DTS-2 warm-back profiles, Well-A.

Fig. 7. DTS-1 injection profile 3, Well-A.

Fig. 5. DTS-1 injection profile 1, Well-A.

Fig. 8. DTS-1 injection profile 4, Well-A.

Fig. 6. DTS-1 injection profile 2, Well-A.

16

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

frac ports, with no disturbance of the slope across the second

frac ports. It can therefore be confirmed that the expected frac

port was open after the repetitive trials and that the abnormal

higher pressure was for activation of the port. Open hole packers 1 and 2 were determined to be sealing, as the DTS profiles

did not show any sharp disturbance across their depths.

The DTS-2 warm-back profiles confirmed the above

interpretations (the sealing of open hole packers 1 and 2) and

additionally allowed us to inquire about the zone injectivity

across the depths of frac port-1. The injectivity is low into the

zone between frac port-1 and open hole packer-2, while it is

better in the middle of the interval between frac port-1 and

open hole packer-1. Zones that take longer to warm-back are

associated with higher injectivity than a zone that recovers

temperature faster.

Based on the above real-time DTS measurements, it was

decided to pull the CT out of hole and proceed with the first

fracturing stage, which was performed successfully.

Job Execution — Well-B

After displacing the wellbore to brine and while pressurizing

the MSF completion5 to open the pressure activated frac port,

frac port-1, at the toe, it was noticed that there was already a

low injectivity to the formation. At this stage, the client decided to switch the CT services provider to mobilize a FOECT

unit and perform the required assessments to decide the way

forward. With the fiber optic cable positioned across all the

frac ports, a DTS-0 baseline profile was taken, Fig. 9. Next, an

injection through the annulus CT was initiated while taking

the DTS-1 profiles, Fig. 10. Then DTS-2 profiles were taken

after stopping the injection to monitor the warm-back response of the wellbore, Fig. 11.

A very sharp change in the last profile curve of DTS-1 was

Fig. 11. DTS-2 warm-back profile, Well-B.

Fig. 9. DTS-0 baseline profile, Well-B.

Fig. 12. DTS profile (track 2) vs. production logging tools logs (track 3), Well-B.

Fig. 10. DTS-1 injection profile, Well-B.

observed, Fig. 10. This clearly indicates that the injected fluid

was squeezed at the depth of the upper frac port, frac port-4.

Indeed, the interval above frac port-4 was cooling down while

the one below it was still warming up, compared to the DTS-0

baseline, as previously shown in Fig. 9. Another smaller

change in the slope was noticed at the depth of frac port-2,

with absolutely no disturbance of the slope across the pressure

activated frac port-1 at the toe. It can therefore be confirmed

that both frac port-4 and frac port-2 were open, while frac

port-1 was closed. The blind assumption of the MSF completion

provider that the injectivity noticed at the surface was into frac

port-1 was wrong. The DTS-2 profile, Fig. 11, shows the

warm-back results of the DTS after pumps were stopped, and

the cool spot remaining across frac port-4 confirmed the results

observed during DTS-1.

The MSF completion provider did not accept the DTS

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

FALL 2013

17

interpretations and asked the client to run a wireline production logging tool to try to confirm that the correct frac port

was open and all the upper three frac ports were closed.

After pulling out of hole, the same FOECT string was used

to run the wireline real-time production logging tools, without

the need to switch to an e-line logging reel or to call for a wireline unit. In fact, the FOECT system enables the connecting of

any real-time production logging tools below an electric-tooptical converter at the BHA level. The logging data gathered

with the FOECT acquisition system are displayed similarly to

a standard wireline format6.

The total downhole flow rate, measured in real time with

the production logging spinner tool (Fig. 12, track 3, green

curve), was clearly and definitely confirming the DTS interpretations as most of the injected fluid was squeezed into frac

port-4 while the remaining fluid was squeezed into frac port-2.

Based on the above facts, the MSF completion provider

acknowledged the malfunction of the frac ports.

FOECT PROFILING

After it was proved that the MSF completion components

could have mechanical malfunctions and that the DTS measured in real time with the FOECT system can detect these defects, the following innovative profiling procedure has been

proposed to confirm if the MSF completion is ready for the

next fracturing stage, and to optimize the design, execution

and evaluation of the fracturing treatment.

1. RIH with the FOECT string to tag the end of the MSF

completion.

2. Take a DTS baseline.

3. Displace the wellbore to the required brine.

4. Pressure up the MSF completion system through CT to the

predetermined pressure to open the first frac port at the toe.

5. Take DTS-1 profiles while injecting brine through the

annulus CT.

6. Take DTS-2 profiles after stopping the injection.

7. Confirm if the correct frac port is the only one open and if

its corresponding open hole packer is sealing.

8. In case of positive results, perform DataFRAC while taking

real-time measurement of the BHPann with FOBHA and

acquiring DTS profiles.

9. After the DataFRAC, take real-time measurements of the

BHT log and DTS profiles.

10. Adjust the fracturing design to optimize its execution

phase.

11. Pull the CT out of hole then perform the first fracturing

stage.

NOTE: It may be possible to keep a small outer diameter

FOECT in hole to monitor and adjust in real time the

execution of an acid fracturing treatment.

12. After the fracturing stage, RIH with the FOECT string to

perform DTS profiles to evaluate the job and assess the

18

FALL 2013

SAUDI ARAMCO JOURNAL OF TECHNOLOGY

isolation of the open hole packers after the treatment.

13. Open the next frac port toward the heel. This can be done

in one of three ways:

a. By dropping the required ball then pressurizing the

MSF completion.

b. With a contingency CT run using a special ball-shaped

BHA and a TC sub in the FOBHA to control the weight

on bit.

c. With a CT run using a special frac sleeve activation

BHA and a TC sub in the FOBHA.

14. Repeat steps 5 to 13 as needed.

CONCLUSIONS

1. The MSF completion components can experience some

mechanical malfunctions (case study of Well-B) that cannot

be detected without a real-time downhole monitoring

system.

2. The real-time DTS measured with the FOECT system is

needed to assess the downhole condition of the MSF

completion components, eliminate blind assumptions, and

confirm if the correct frac port is open and its open hole

packers are sealing so as to proceed with the fracturing

stage based on measured facts.

3. The DTS interpretations are consistent with the ones

obtained from production logging tools.

4. The FOECT profiling should be used not only to assess the

functionality of the first frac port at the toe of the MSF

completion, but also to confirm the readiness before every

fracturing stage.

5. The FOECT system can also be used to perform

DataFRAC and get real-time downhole measurements to

adjust the fracturing treatment design, optimize its

execution and improve its evaluation.

ACKNOWLEDGMENTS

The authors would like to thank Saudi Aramco and Schlumberger management for the permission to present and publish

this article. Special thanks go to all Saudi Aramco and Schlumberger operation team members who participated in these jobs

and made them successful.

This article was presented at the SPE Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi,

U.A.E., November 11-14, 2012.

REFERENCES

1. Rahim, Z., Al-Kanaan, A.A., Johnston, B., Wilson, S., AlAnazi, H.A. and Kalinin, D.: “Success Criteria for

Multistage Fracturing of Tight Gas in Saudi Arabia,” SPE

paper 149064, presented at the SPE/DGS Saudi Arabia

Section Technical Symposium and Exhibition, al-Khobar,

Saudi Arabia, May 15-18, 2011.

2. Al-Ghazal, M., Abel, J.T., Wilson, S., Wortman, H. and

Johnston, B.: “Coiled Tubing Operational Guidelines in

Conjunction with Multistage Fracturing Completions in the

Tight Gas Fields of Saudi Arabia,” SPE paper 153235,

presented at the SPE Middle East Unconventional Gas

Conference and Exhibition, Abu Dhabi, U.A.E., January

23-25, 2012.

3. Schlumberger: “The Essentials of Fiber Optic Distributed

Temperature Analysis,” 2005.

4. Finkbeiner, T., Freitag, H-C., Siddiqui, M., Woudwijk, R.,

Joseph, K. and Amberg, F.: “Reservoir Optimized

Fracturing — Higher Productivity from Low Permeability

Reservoirs Through Customized Multistage Fracturing,”

SPE paper 141371, presented at the SPE Middle East Oil

and Gas Show and Conference, Manama, Bahrain,

September 25-28, 2011.

5. Vargus, G., Howell, M., Hinkie, R., Williford, J. and

Bozeman, T.: “Completion System Allows for