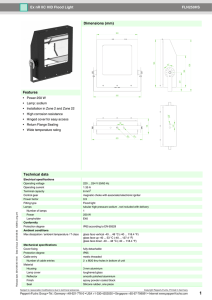

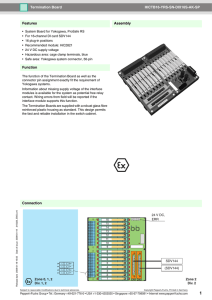

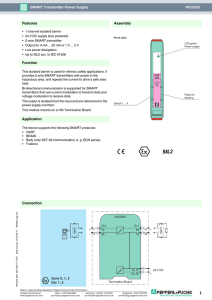

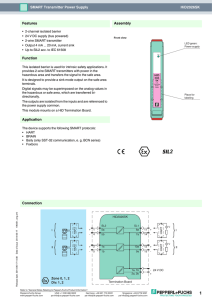

FIELD DEVICES FOR PROCESS AUTOMATION

advertisement