Substrates - Electronic Fine Ceramics

advertisement

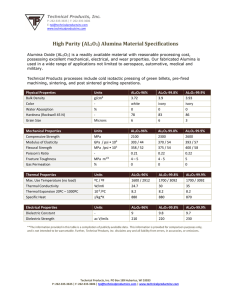

CERAMIC MANUFACTURING PROCESS RAW MATERIAL COMPOUND MIXING AND MILLING SPRAY DRYING SLIP TAPE CASTING ROLL COMPACTION DRY PRESSING EXTRUSION FIRING DRYING MACHINING CUTTING STAMPING SINTERING SINTERING GLAZING GRINDING AND LAPPING FIRING LASER SCRIBING INSPECTION INSPECTION INSPECTION PRESSED AND EXTRUDED PARTS LASER SCORED SUBSTRATE GLAZING INSPECTION SMOOTH SUBSTRATE FOR THIN FILM TAPE SUBSTRATE FOR THICK FILM GLAZED SUBSTRATE Tape Substrates for Thick Film We are producing 96% alumina substrates (A-476) and 93% alumina substrates (A-473T) which have excellent thick film reliability and consistency. ■Features Our substrates have excellent thick film reliability and precise dimensional tolerance control (Super premium: ±0.25%). They are cost effective for through-hole processes with small diameter holes (Min. 0.2mm) allowing densification of precision circuitry. ■Application Hybrid lntegrated Circuit Resistor Network Chip Resistor Potentiometer Focus Substrate, etc ■Characteristics of Material Item Material Material Code Alumina (Al2O3) A-476 (Tape) White Color Alumina Content Bulk Density Water Absorption A-473T (Tape) Dense Appearance % 96 92 kg/m3 3.7 × 103 3.6 × 103 % 0 0 Vickers Hardness (Hv 1.0) GPa 13.7 12.3 Flexural Strength MPa 350 310 Young's Modulus GPa 320 280 40-400˚C 7.2 × 10-6/˚C 6.9 × 10-6/˚C 40-800˚C 7.9 × 10-6/˚C 7.8 × 10-6/˚C Coefficient of Linear Thermal Expansion Thermal Conductivity (20˚C) Dielectric Strenght Volume Resistivity Dielectric Constant (1MHz) Dielectric Loss Angle (1MHz) Surface Roughness W/(m ⋅ K) 24 22 V/m Ω ⋅ cm (20˚C) 12 × 10-6 >1014 12 × 10-6 >1014 (300˚C) 1010 1011 (500˚C) 108 109 – 9.4 8.8 × 10-4 4 6 Ra µm 0.2-0.80 0.2-0.80 ■Design Guideline Unit: Inch (mm) Surface Roughness Tape Manufacturing Method Punched/Greenscored Laser Scored Standard:±0.8%NLT±.004 (0.10) Premium:±0.5%NLT±.003 (0.08) Length & Width Tolerance Super Premium: ±0.25%NLT±.002 (0.05) +.008 (0.20) –.002 (0.05) As Fired Camber Thickness Availability Thickness Tolerance Size Availability Scribing Tolerance Standard:±0.8%NLT±.004 (0.10) Premium:±0.5%NLT±.003 (0.08) Super Premium: ±0.25%NLT±.002 (0.05) Edge to Scoreline: +.008 (0.20) –.002 (0.05) Scoreline to Scoreline: ±.002 (0.05) Parallelism Standard:0.5% of outside dim. ±.002 (0.05) Perpendicularity Premium:0.3% of outside dim. Corner R Hole Size Spacing Between Holes or Edge to Holes Surface Roughness .020 (0.51) * .008 (0.20) Dia. Min. * .015 (0.38) Square Min. Minimum equal to * thickness of substrate NLT±.020 (0.51) A-476: 8 to 30 µ inch CLA (Ra 0.2-0.75 µ m) A-473T: 8 to 30 µ inch CLA (Ra 0.2-0.75 µ m) A-473T (93% Alumina) ■Application ■Features ● Thick ● Uniform film hybrid IC ● Focus grain size and small voids ● Equivalent substrate, and others ● Less ● Larger ● Tight SEM (A-473T) size can be produced (Max. 8" × 10") tolerance:Standard: ±0.5% ● Same 5.00 µm to A-476 for thick film characteristics camber and edge-curl Premium: ±0.25% surface roughness on both sides Pressed and extruded parts As a leader in ceramic developement and one of the largest manufacturers of advanced ceramics in the world, Kyocera offers a complete line of ceramics with features such as; excellent electrical insulation at high frequency, high mechanical strength, high heat resistance, high wear resistance, extremely low thermal expansion and excellent chemical resistance. Kyocera's advanced dry pressing and extrusion technology can provide complicated designs and precise dimensional tolerances. ■Characteristics of Material Material ALUMINA (Al2O3) Item Material Code A-459 A-445 A-473 Appearance A-476 A-479 A-479SS A-480S Dense Color Russet Dark brown White Ivory Al2O3 90% Al2O3 91% Al2O3 92% Al2O3 96% Al2O3 99% Al2O3 99.5% Al2O3 99.7% Alumina Content High Mechanical Strength, High Temperature Resistance, High Frequency Insulation, High Chemical Resistance Good for Light Good for Good Surface Hard and Hard and Metallizing Intercepting, Metallizing, Smoothness Chemically Chemically High Heat Mechanically Stable Stable, Dissipation Strong Fine Grain Strong and Smooth Electrical Characteristics Thermal Mechanical Characteristics Characteristics Main Characteristics Bulk Density Water Absorption Vickers Hardness (HV1.0) Flexural Strength Compressive Strength Young's Modulus Poisson's Ratio Fracture Toughness kg/m3 % GPa MPa MPa GPa – m MPa√ 40~400˚C Coefficient of Linear Thermal Expansion ×10 -6/˚C 40~800˚C Thermal Conductivity W/m ⋅ K Specific Heat J/kg ⋅ K Heat Shock Resistance (Put in water) ˚C V/m Dielectric Strength 20˚C Ω ⋅ cm Volume Resistivity 300˚C 500˚C Dielectric Constant (1MHz) – (×10 -4) Dielectric Loss Angle (1MHz) Loss Factor (×10 -4) JIS C2141 JIS C2141 JIS R1610 JIS R1601 – JIS R1602 JIS R1607 JIS R1618 JIS R1611 JIS R1611 – JIS C2141 3.6 x 103 0 11.8 310 – 280 0.23 – 7.0 7.9 14 0.75 x 103 – 12 x 106 >1014 1011 109 8.8 6 53 3.8 x 103 0 12.7 290 – 320 0.24 – 7.3 8.1 12 0.75 x 103 – 12 x 106 >1011 107 106 9.8 25 245 3.6 x 103 0 12.3 310 2,300 280 0.23 – 6.9 7.8 18 0.75 x 103 200 12 x 106 >1014 1012 1010 9.0 6 54 3.7 x 103 0 13.7 350 – 320 0.23 – 7.2 7.9 24 0.75 x 103 200 12 x 106 >1014 1010 108 9.4 4 38 3.8 x 103 0 15.2 270 2,160 360 0.23 4.6 7.2 8.0 29 0.75 x 103 200 12 x 106 >1014 1010 108 9.9 2 20 3.8 x 103 0 15.2 340 2,350 370 0.23 4.2 7.2 8.0 32 0.75 x 103 250 12 x 106 >1014 1013 1010 9.9 1 10 High Purity, High Chemical Resistance, Good Anti-Plasma, Wear Resistance 3.7 x 103 0 16.2 350 – 380 0.23 – 7.2 8.0 32 0.75 x 103 – 12 x 106 >1014 1013 1010 9.9 1 10 MULLITE (3Al2O3 ⋅ 2SiO 2) K-690 ML-652 S-210 ZIRCONIA (PSZ) FORSTERITE (2MgO ⋅ SiO 2) STEATITE (MgO ⋅ SiO 2) S-211 Porous F-1120 F-1023 Z-201N Dense White Dark brown White Dark brown – – – – – – Excellent Thermal Shock Resistance Thermal Insulator Good Light Shield Good Surface Finish High Thermal Expansion High Mechanical Strength, Excellent Wear Resistance, Good Surface Finish, High Fracture Toughness 2.8 x 103 0 5.4 180 – 120 0.24 – 7.4 8.0 2.2 0.71 x 103 – 13 x 106 >10 14 1010 107 6 18 – 3.1 x 103 0 6.4 180 – 130 0.22 – 9.2 10.4 2 0.71 x 103 – 13 x 106 >10 14 107 107 8 750 – 3.0 x 103 0 6.9 160 – 150 0.24 – 9.7 – 5 0.75 x 103 – 13 x 106 >10 14 1010 1010 6.5 5 – 3.0 x 103 0 5.9 160 – 150 0.24 – 10.1 – 5 0.75 x 103 – 13 x 106 >10 14 109 109 6.5 5 – 6.0 x 103 0 12.3 980 5,690 210 0.31 4.5 10.5 11.0 3 0.46 x 103 300 – – – – – – – Very low Thermal Expansion Very low Thermal Expansion 2.0(Bulk) x 103 10~20 – 30 – – – – 4.1 4.8 1 0.67 x 103 – – – – – – – – 3.2 x 103 0 10.8 280 – 210 – – 5.0 5.8 5 0.75 x 103 – 12 x 106 >10 14 1012 109 7.4 20 148 1kgf/mm 2=9.807MPa Milky white Light yellow 1cal/cm ⋅ sec ⋅ ˚C=418.7W/(m ⋅ k) 1cal/g ⋅ ˚C=4.187J/ g ⋅ K=4.187x10 3J (kg ⋅ K) Thin Film Substrates For thin film deposition, we have 99.6% alumina substrates (A-493, A-494) which offer excellent surface smoothness. ■Characteristics of Material Item Surface Roughness Unit: Inch (mm) Unit Side A: CLA µinch (Ra µm) Side B: kg/m3 Bulk Density µm Grain Size Average Alumina Content Color Water Absorption A-493 A-494 3.0 (.08) 2.0 (.05) 5.0 (.125) 4.0 (.10) 3.86 × 103 < 1.5 < 1.0 Wt% 99.6 – White – Nil 1MHz 9.9±.2 Dielectric Loss Angle 1MHz Volume Resistivity Ω ⋅ cm 2 × 10-4 > 1014 (25˚C) 33 30 25 Dielectric Constant Thermal Conductivity 25˚C 300˚C 500˚C Wm/ ⋅ k per˚C Coefficient Of Linear 25 to 300˚C 7.2 × 10-6 Thermal Expansion 25 to 600˚C 7.4 × 10-6 25 to 800˚C 8.2 × 10-6 MPa 550 Flexural Strength Design Guideline Thickness SEM A-493 A-494 Thickness Unit: Inch (mm) Standard: .010 (0.25), .015 (0.38), .025 (0.635) Minimum: .005 (0.127) Maximum: .040 (A493), .027 (A494) Tolerance Standard: ±10% NLT±.002 (0.05) Premium: ±5% NLT±.0008 (0.02) 6.0 µm 6.0 µm Length, Width Item Green Score Surface Roughness Tolerance A-493 Laser Score 4.7" × 4.7" (120 × 120) Max Size Standard: ±0.8% NIL±.004" Premium: ±0.5% NIL±.003" (0.10) Standard: +.008"/-.002" (+0.2/-0.05) Premium: (Thickness:0.020"orLESS) (0.08) ±.004"/-.002" (+0.1/-0.05) Perpendicularity Straightness a 100 µm L A-494 L Perpendicularity b 1 µm Straightness Standard: a=L × 0.5% b=L × 0.5% Premium: a=L × 0.3% b=L × 0.3% .002" Polished Substrates For Thin Film ■Features ● Excellent ● Tight surface quality for thin film application. dimensional tolerances (thickness, flatness). ■Material ● Kyocera A493, A494 (99.6% alumina) ● Available ● .002" ●8 thickness .010"-.0315" (0.25-0.80mm) thickness is available with maximum size of 2" × 2" and µ inch surface finish. ■Visual Defects ● Scratches: ● Voids: .0003" deep max. .0008"dia max. ● Contamination: Not allowed (by naked eye) Surface Roughness Data 100µm 0.5µm A-493 Standard A-493 Premium ■Surface Roughness Unit: Inch (mm) Standard 1.2 µ inch CLA (Ra0.03 µ m) Premium 0.4 µ inch CLA (Ra0.01 µ m) A-494 Standard ■Thickness Tolerance Unit: Inch (mm) Size Less than 3" 3" or more Standard ±.0008 (0.02) ±.0020 (0.05) Premium ±.0004 (0.01) ±.0008 (0.02) A-494 Premium ■Flatness Size (inch) Unit: Inch (mm) Standard One side polished Premium Both sides polished One side polished Both sides polished 2 × 2 × .010 .0020 (0.05) 2 × 2 × .015 .0016 (0.04) .0012 (0.03) .0010 (0.025) .0006 (0.015) 2 × 2 × .025 .0008 (0.02) .0006 (0.015) .0005 (0.013) .0004 (0.01) 3 × 3 × .010 .0036 (0.09) .0030 (0.075) .0020 (0.05) .0016 (0.04) 3 × 3 × .015 .0032 (0.08) .0024 (0.06) .0016 (0.04) .0012 (0.03) 3 × 3 × .025 .0024 (0.06) .0016 (0.04) .0012 (0.03) .0008 (0.02) 4 × 4 × .010 .0200 (0.50) .0120 (0.30) .0100 (0.25) .0050 (0.13) 4 × 4 × .015 .0100 (0.25) .0060 (0.15) .0050 (0.13) .0032 (0.08) 4 × 4 × .025 .0032 (0.08) .0024 (0.06) .0020 (0.05) .0016 (0.04) 4.5 × 4.5 × .015 .0200 (0.50) .0140 (0.35) .0120 (0.30) .0080 (0.20) 4.5 × 4.5 × .025 .0080 (0.20) .0060 (0.15) .0050 (0.13) .0040 (0.10) max. .0016 (0.04) max. .0014 (0.035) max. .0010 (0.025) max. Glazed Substrates for Thermal Printheads ■Features Kyocera glazed substrates consist of 96% alumina with a glass overcoat. They have superior flatness and fewer surface defects so it is very applicable for thermal printheads used in advanced and downsized facsimile machines. Kyocera can provide various types of glazed substrates for each application such as partial glazed, full glazed and serial glazed substrates. Glazed Substrates 1.Partial Glazed Substrates Used in both thin and thick film types of thermal printheads for high speed G3 and G4 type facsimiles and color printers. Heater elements are put on a 1 to 3 mm narrow glazed portion to allow thermal printheads to closely fit a sheet of thermal paper and provide very clear and crisp printing. Glazed Part 2.Full Glazed Substrates Used in thick film type of thermal printheads for regular type of facsimiles. The glazed surface is quite flat and the meniscus at the edges are low, so the full glazed substrates allow thermal printheads print very clear words. Glazed Part 3.Serial Glazed Substrates Used in thermal printheads for wordprocessors and bar code printers. The dimensional tolerances of glaze pitch are very tight allowing the distance between the substrate edge and the glazed portion for heater elements to be short and the width of the glazed portion to be narrow so high speed printing is possible. Glazed Part ■Glazed Substrate Material Specification Item Unit Condition GS-5 GS-71 Glass Transition Temperature ˚C – 669 680 Glass Softening Temperature ˚C – 856 1/˚C R. T. to 400˚C 6.6 × 10 6.8 × 10-6 W/m ⋅ k 20˚C 0.83 0.75 20˚C >1014 >1014 300˚C >1014 >1014 500˚C 2.8 × 1010 2.1 × 1010 Coefficient of Linear Thermal Expansion Thermal Conductivity Ω ⋅˚C Volume Resistivity 870 -6 Dielectric Constant – 1MHz 20˚C 7.2 8.7 Dielectric Loss Angle – 1MHz 20˚C 14.6 × 10-4 10.0 × 10-4 Surface Roughness Ra µm <0.02 <0.02 ■Glazed Substrate Design Guideline Unit: Inch (mm) STD Dimensions Item Thickness STD Tolerance Premium Tolerance .025 (0.635) ±.0024 (±0.06) ±.0016 (±0.04) .032 (0.800) ±.0032 (±0.08) ±.0024 (±0.06) .040 (1.000) ±.0040 (±0.10) ±.0032 (±0.08) ±.080 (±0.20) ±.040 (±0.10) ±.080 (±0.20) ±.040 (±0.10) Full Glaze .024 max. (0.6 max.) .020 max. (0.5 max.) Partial Glaze .020 max. (0.5 max.) .016 max. (0.4 max.) Full Glaze .020 max. (0.5 max.) .016 max. (0.4 max.) Partial Glaze .016 max. (0.4 max.) .012 max. (0.3 max.) ±.0006 (±15µm) ±.0004 (±10µm) ±.0004 (±10µm) ±.00028 (±7µm) .0008 max. /.120 .0006 max. /.120 L:12.44 max. (316 max.) Outside Dimensions W:3.15 max. (80 max.) Thickness .025/.032 Camber (0.635/0.8) Substrate Size: 9 × 3.1 (230 × 80) Glaze Thickness: .0027 (70 µm) Thickness .040 (1.0)t Full Glaze: .0018 to .0032 Glaze Thickness (45 to 80µm) Partial Glaze: .0012 to .0024 (30 to 60µm) Meniscus of Full Glazed Substrates .120" from all edges Glaze thickness of partial glazed substrate with width of less than .035" is .002" max. (3mm) (20µm max./3mm) (15µm max./3mm) Microwave Dielectric Ceramics 1.Filter, Isolator, MIC ■Features ● Miniaturization of circuit size is possible due to the ceramic's ■Features high dielectric constant. ● Downsizing ● High ● Q values even at high frequencies. Stable circuit operation can be obtained due to the low temperature coefficient of the dielectric constant. ● Because of a wide range of dielectric values, circuit design can be tailored to fit the application more easily. ● Surface finish can be selected to allow use with thin film or thick film technologies. ● 2.Dielectric Resonator (DR) (Satellite Broadcast, Base Station) Numerous custom designs such as holes, complicated 3 dimensional shapes, and snaplines are available due to Kyocera's advanced dry press technology. of DR or cavity is possible because of high ε γ and high Q value. ● Stable electrical characteristics ■Characteristics of Material Material Code Dielectric Constant Q value SM200 εγ (GHz) SM210 SH790 SH890 SH110 SB350 SL390 SV430 35~37 39~42 43~46 20±1 21±1 79±1 89±1 110±3 >8000 >8000 >1500 >1800 >1200 (6) (6) (2.6) (2.6) (2.3) 4500 6500 4400 (10) (10) (10) τε τε τε τε τε τf τf τf -25±30 -25±30 -35±30 -35±30 -70±30 0±1~8±1 -3±1~8±1 -7±1~8±1 1/˚C 9.2 × 10-6 9.2 × 10-6 10.1 × 10-6 9.0 × 10-6 W/m ⋅ k 7.5 7.5 2.1 2.1 2.1 2.9 2.9 2.9 Bulk Density kg/m3 3.7 × 103 3.7 × 103 5.7 × 103 5.7 × 103 5.7 × 103 4.6 × 103 5.6 × 103 4.8 × 103 Flexural Strength MPa 190 190 180 180 180 180 100 290 Water Absorption % 0 0 0 0 0 0 0 0 Temperature Coefficient (τ ε or τ f) Coefficient of Linear Thermal Expansion (40~400˚C) Thermal Conductivity ppm/˚C Application MIC Filter/Isolator/MIC ■Shapes ● Snaplines and via holes can be added by the pressing process. ● Products 10.1 × 10-6 10.1 × 10-6 can be designed to the customer's individual specifications and requirements. 10.3 × 10-6 10.2 × 10-6 DR Aluminum Nitride Substrates ■Features ● High thermal conductivity (7 to 8 times as much as Al2O3) ● Thermal expansion is close to Silicon wafer. ● High mechanical strength and high density. ● High chemical durability. ■Characteristics of Material Item Materials AN215 AN217 Color – Black Light Russet 3 Bulk Density g/cm Thermal Conductivity Thermal Characteristics Coefficient of Linear Thermal Expansion Electrical 3.4 W/m ⋅ k 150 170 ×10-6/˚C RT~400˚C 4.8 ~800˚C 5.4 Dielectric Strength V/m Volume Resistivity Ω ⋅ cm ■Characteristics Comparison (AIN/AL2O3) Thermal Conductivity (W/m ⋅ K) 200 12 × 10-6 150 Dielectric Strength V/m × 106 14 >10 Characteristics Dielectric Constant 1MHz Dielectric Constant (1MHz) 10 100 20 15 8.7 50 10 5 5 Dielectric Loss Angle 1MHz (×10-4) Hardness (Hv1.0) 3 GPa 100 Flexural Strength MPa 10.8 400 500 Mechanical Characteristics Flexural Strength MPa 310 Young's Modulus GPa 300 2.5 5 Dielectric Loss Angle 1MHz (×10-4) 5max AIN Al2O3 10 Thermal Expansion *10-6/˚C (RT-400˚C) ■Thermal Characteristics ■Thermal Conductivity VS Temperature 300 300 SiC 250 BeO Thermal Conductivity (W/mK) Thermal Conductivity (W/mK) 200 300 200 ALN 150 100 Si 50 GaAs BN Al2O3 0 BeO 250 200 AN217 150 AN215 100 50 Al2O3 0 1 2 3 4 5 6 Thermal Expansion (10-6/˚C) 7 8 9 1 50 100 150 Temperature (˚C) 200 250 Multiform Glass ■Features ● High thermal resistivity ● Excellent ● Sealing dielectric strength ● High mechanical strength ● High electrical resistivity operation is made simple ■Characteristics of Material Item Unit Characteristics Material Code Coefficient of Linear Thermal Expansion G901 1/˚C G902 30~380˚C 24.0±1.5 (×10-7) 27.5±1.5 (×10-7) Annealing Temperature ˚C 525 520 Softening Temperature ˚C 825 820 Strain Point ˚C 470 3 465 3 Bulk Density kg/m 2.15±0.05×10 Flexural Strength MPa 45 20˚C Volume Resistivity Dielectric Strength >1014 Ω ⋅ cm 300˚C 1012 500˚C 109 V/m Viscosity-Temperature Curve 25 (120) × 10 -6 (120) is measured by direct current using .010 thickness test piece. Strain point 14 Annealing point 12 Cathode-Ray Tube Log Viscosity (poise) 10 8 Softtening point 6 Working-point 4 2 0 400 600 800 1000 1200 Temperature (˚C) 1400 1600 Magnetic materials Ferrite Soft magnetic materials Ferrite ■Features ● Manufactured by the highest technical ceramic manufacturer in the world. ● Many standard materials to fit your application. ● Complex shapes, high precision are no problem with Kyocera outstanding pressing technology and are available at competitive prices. ● The industry's best selection for magnetic shielding for SMT components or entire circuit. ● Metallization is also available. ■Characteristics of Material Code No. NZ001A NZ021A NZ112A NZ131A NZ221A NZ241A NZ273B NZ311A NZ312B NZ341A NZ411A NZ411B NZ511A NZ511G 100kHz 1 7 65 160 370 480 150 650 490 900 800 1,100 2,000 450 1MHz 1 7 65 160 370 480 150 650 500 950 800 1,200 1,500 430 10MHz 1 7 65 160 220 300 160 270 260 330 200 250 240 220 26,000 200 150 30 15 120 20 15 15 50 15 15 80 3,600 130 80 60 30 50 55 60 65 80 120 360 210 1,300 180 280 3,000 2,700 80 4,500 3,200 4,400 4,700 5,300 9,600 4,400 35 0 50 4 15 15 20 0 20 25 15 7 8 35 0 35 2 7 10 10 –1 9 15 6 2 –2 Saturated Magnetic Flux Density Bs (mT) 80 380 370 290 350 250 390 290 360 380 380 320 230 Residual Magnetic Flux Density Br (mT) 20 230 160 110 120 90 210 110 160 190 170 100 130 108 108 108 108 108 108 108 108 108 108 108 108 108 Initial Permeability 100kHz (×10-6) Relative loss factor 1MHz (tan δ / µ) (×10-6) 10MHz (×10-6) –25~20˚C Relative Temperature Coefficient (α µ r) (×10-6) 20~80˚C (×10-6) Electrical Resistivity (Ω ⋅ cm) 108 ■DESIGN GUIDELINE DR CORE SQUARE CORE ● Both ● Both ● d, alumina and ferrite are available. W&w depends on D&t. alumina and ferrite are available. ● Complicated shape, high precision are no problem with D 7.0 (d) 0.8 D' 7.0 (D) 1.0 (t) 1.0 (W) 0.2 (w) 0.25 d t d 1.5 d' 1.5 w W Minimum Dimension UNITS:mm D KYOCERA out-standing press technology. t φd φD 0.4 d' D' l 1.0 t l t 2t+l 7.0 UNITS:mm PUSHPIN CORE CAP CORE ● Suitable ● Suitable ● Using for magnetic shielding components. with cap core, low-height is possible. ● Square ● Using for magnetic shielding components. type is suitable for auto mounting system. with pushpin core, low-height is possible. 2.5 A 10.0, 1.0 C 5.0 A = φ2.2~6.0 A 4.5 UNITS:mm D 0.3 D 0.5 atC 3.0 at3.0 C 5.0 Minimum dimension of B&D in round pot cores as follows B 0.4 D 0.3 NOTE:B&D depends on A&C A METALIZATION (2520) 0805 (2012) A B 0.45±0.15 0.2MAX. 0.40±0.15 0.1MAX. normal metalization 0603 0.15 (1608) +0.25/–0.10 0402 0.15 (1005) +0.25/–0.10 side metalization flat metalization figure 0.3-0.8 0.1-0.35 A 1008 Ag(Ag/Pd)+Ni+Sn/Pb(Au) Alumina & Ferrite core with metalization alumina and ferrite are available. B ● Both B 0.8 at6.0 A C 0.5 D B 0.5 at4.0 A 6.0 D C B 0.3 atA 4.0 D φ1.2 C B B B 0.1 0.1MAX. 0.1MAX. Ag(AgPd)+Ni+Sn/Pb good point alumina –––– good adhesion higt Q (45 at 25MHz) ferrite –––– good adhesion higt Q (28 at 8MHz) Single Crystal Sapphire Substrates ■Sapphire ■Features ● Perfect ● Mirror ● Low ● High control of crystal orientation. (Fig. 1) polished surface. dielectric loss: Tan δ <10-4. thermal conductivity. ● Excellent chemical durability. Crystal Orientation (Fig.1) ■SOS Substrates ■Features ● SOS ■Characteristics of Material Material Code SA-100 Appearance Dense Color Transparent Principle Materials Al2O3 3.97 × 103 Bulk Density (kg/m3 ) Water Absorption (%) 22.5 Flexural Strength (MPa) 690 Young's Modulus (GPa) 470 Coefficient of Linear Parallel to C-axis 5.3 × 10-6/˚C Thermal Expansion at 25˚C (1/˚C) Vertical to C-axis 4.5 × 10-6/˚C Thermal Conductivity (W/mk) 41.9 48 × 106 Dielectric Strength (V/m) 20 ˚C 1016 300 ˚C – 500 ˚C 1011 Parallel to C-axis 11.5 Dielectric Constant (1MHz) Vertical to C-axis Dielectric Loss Angle (1MHz) circuit miniaturization. (Fig.2) ● Applicable ● Excellent ● Simplify for high speed circuits. radiation hardness. IC designing and process. 0 Vickers Hardness (GPa, Hv 1.0) Volume Resistivity (Ω ⋅ cm) (Silicon On Sapphire) structure. ● Enable 9.3 <10-4 Comparsion in structure and individual chip size of SOS and bulk silicon