Rodent Vivarium Design Standards at MD Anderson

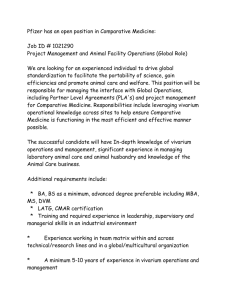

advertisement