Ash glazes, local slip glazes and once fire process

advertisement

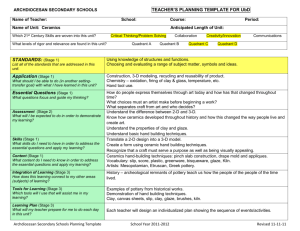

Rochester Institute of Technology RIT Scholar Works Theses Thesis/Dissertation Collections 6-1-1976 Ash glazes, local slip glazes and once fire process Howard Skinner Follow this and additional works at: http://scholarworks.rit.edu/theses Recommended Citation Skinner, Howard, "Ash glazes, local slip glazes and once fire process" (1976). Thesis. Rochester Institute of Technology. Accessed from This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion in Theses by an authorized administrator of RIT Scholar Works. For more information, please contact ritscholarworks@rit.edu. ASH GLAZES, and LOCAL SLIP GLAZES ONCE FIRE PROCESS BY Howard Skinner B.F.A. Rochester Institute June, 1976 of Technology- Preface My findings have which development techniques surface for writing this reasons steady line glazes, be will striving to join into these myself natural clay glazes process itself. great This ash savings fire once glaze clay by a one of the step with the to Also the was used on a accessories. closeness of the fire method which time-wise, ash by a and clay-forming joins the raw from raw has clay and raw 11. in resulted slip clay quality clay to finished process. the ecologically. and taking away the fresh fired glaze stismlated of fire the investigation has led toward once process areas and my into the once ash to be enough relation economically, without being consistent oriented an functional dinnerware of Investigation development of present explorations local slip glazes, the production and which from my resulted ash of thesis is to of product the in TABLE OF CONTENTS I. Preface Page 1 II. Introduction Page 2 III. Problem 1. Location 2. 3. Reasons for once fire technique Treatment of slip readying for glaze 4. Combining 5. Kinds of wood ash Ash glaze additions Ash chemical analysis Ash glaze colorants Glaze applications Once fire clay body considerations Design elements for once fire 6. 7. 8. 9. 10. 11. IV. of natural slips and glaze slips ashes Page 3 Page 3 Page 5 Page Page Page Page Page Page Page Page 6 6 7 8 9 13 14 15 Page 15 Conclusion 111, ASH GLAZES, LOCAL SLIP GLAZES ONCE FIRE PROCESS and glaze formulas are available provided in books and periodicals Many mation companies. glaze formulate should instant from So why my own else to be far cupboard a glaze used removed on it down, bag it, which glaze, I have glaze no which can be slip glaze and the made one else made ash so my and surface I may do wood screen it, own ball slip glaze to glaze. 1. comes of I If which When I mill I produce want ashes can I dig it, dry it, base for my to use united another from burned also still my individualized the formed pottery is glaze. a ready for has been spirit glaze when commercially created. by using the into own from the do. can movement which my are pottery of one slips clay particular to the go reproduce seem slake in natural own commercial to why formulas glaze or into the pottery that I have This way I and someone glazes. a glazes making my should would clay, then and by This put me chemicals developed work? unknown with as It is transmitted through the within. prepared have To use. hands. dealing obtainable proven other asked glazes from and The question may be infor from the today combine another the type of 2. Ash texture would can which sarily the these glazes, smooth The glazes a the qualities fully developed which may be of will in potters. Two have described slip Rhodes known who wrote potter produce for glaze the which Rochester introduced Institute me to introduction led separately with other varying by I or by a me whose and glazes ash observed of combining formulas when surfaces stemmed pottery. from from personally I have once used are read and and One summer well at Technology is Frans Wildenhain. consider combining It textures using who Daniel Potter. of by techniques fire my first shore both use production and the for textural will glaze elements and during slip from the to rough and dinner- In surface. Pioneer Pottery Glazes and rough has books authors chemicals. surface glaze of of quality elements it be qualities in making use neces suit These consistent not to surface eating varying ware my accenting from reading books Clav whom an glazes. Michael Cardew who wrote are or ash in ways of a develop either the to applied smooth natural gleaned observing the other a reproduced Interest information use against played inherant to be are to wish developing reflecting both surface variations surface In gradation. for example, ware, I which is This once. steady textursil quality a rough or produced ash to have considered often only be case. maintain smooth is surface glaze He lake Ontario. natural slips and This ashes them or by further combining them led me in the direction also available by using them for textural effects. slips or of ash th* alone, The in ways of purpose which efforts my glaze natural chemically to form a making it for possible to be fired once therefore, and, gas glaze which would a has been to elements over a applied time on combined thus over clay body a the bisque firing stage, eliminate down cut be fire body? once to be glaze would could develop and seek for loading, on and for firing. used When seeking the clay from which are glazes slip one made, * look for must spots of vein clays located. are road construction sides can be found Usually the in a vein of be will organic bank whole It is which Another in drainage ditch beside clay when found of stones particles of clay to observe excavations because good a place that of debris settle are made clay. of rest the of sand, there may be can and a be look for slip clay is to cuts good thus, glazes from stones, however, which road is particularly it free washed size glazing. for slip free from debris quite through cut large bank a be found also may used fairly free Sometimes, for slip This be will debris. clay They different from the color a used a in the found along it necessary to made noticeable vein clay in the bank. other has banks. The best clay to be hills. of river visible most large clay where These banks may be lakes or along the in banks are The clay. sedimentary of shores anf of sedimentary deposits where a though a bank. because nature has leaving in the ditch. for house the smaller It is well to foundations clay deposits may be found below the topsoil. After 4. the slip clay has been located be clay down. the slake through a run dug, it is necessary to and to thirty The to ball the clay into ground the a of for glaze testing in The firing the ranges the to a or feldspar, a or The ash. will contribute it can streaks of the of wood that ash tend could to the result of the of slip into firing after range. may vary widely After clay. a make are finish mat flint silica, added frit to or syenite, is totally firing glazes finish may be mat results often added which chemical will ash kind the are may vary from surface slip to apply the slip slip/s composition the a a more glassy surface, it may be done by adding kaolin zirkopax. ash wood or slip is desired, surface of natural If the Another flux amount these or nepheline pax super the glaze To surface. mat to find should process the makes time order chemical slip high gloss. glassy or of particles This Now it is size. the upon firing, and equal step in the next creamy consistancy. particles depending until slip to free screen mesh sixty from any remaining debris. mill it After the clay becomes slurry, add in the of surface a on it a will be change Fruit-wood a it with surface found can be made glassy, are running texture. In the glaze such hue which choice that the different kinds in the yellow-brown hue varying the By there is glaze slip yellow glaze which ash a slip. the to the slip, make content. to give carries color to the added beauty to the ash, will be to as color apple, the and the for example, glaze. Hard-wood 5. ash, it will wood ash consists to seventy thirty when This is caused magnesia. the glaze be lime, The and make the so doing a mat or better to eight cone The ash the firing the up to potash, phosphorous to further flux altered to the thirty Clay surface of the be controlled. can glaze also must to which the fluxes have been be can can range As acquired. be adjusted a result between of cone eleven. of gloss itself. surface of up to percent form will content chemical whiting. adhere the fluidity opaque these additions, may be possibly ash. iron oxide, of flint or adding kaolin to the glaze added and ten cone alumina, percent surface ash the by traces some glaze to heated up to fifteen silica, adding felspar, By pottery. By by to added up to fifteen percent and darker brown color a by itself of percent give iron than does the fruit-wood more glassy surface. which will maple, contain Any a as such the ash Hard-wood ash may be varied glazes such as maple is by the made up kind of i of Si02- 14.08, Al203-3.69, Fe203-0.94, P205-2.l4, Ca0-35.90, Mg0-5.44, MnO-0.14, K20-1.45, Na20-0. 55. This ash wood ash into a ash also glaze of to the a has different color hue. gives chemically is a a yellow-green made up of: hue glaze Apple color. ash when to the glaze. The Fruit- mixed apple Si02-2.7, ^zO^-k^, CaO-70.9, K20-11.8, Na20-1.9, SO3-2.7 MgO-5.5, cast dark green hue gives which leads to a yellowish color. Some other sources of ash are soft-woods (pine), straw, 6. grass an cuttings ash color and to hue a bleaching and are with in the oxides to these may be slip using such as oxides glazes, spodumene To formula one are all composed produce individual an certain color changes slip, Barnard slip, I chose crystal to produce cobalt glazes, in or weret and oxides flux, a iron, a cobalt color added along glazes. Some any The slip clay. natural art slips Most produce may be Many Albany to add^d Most glaze. as act Rutile, surface. create which They may may be which ash oxides. metalic of color additive. a oxides glaze to any added characteristic. or as red rutile may be colorants agent, copper changes of than more produce will ash of will substance glaze. these colorants have burnable Any every different kind and Additional of leaves. other formulas glaze iron clay saturate manganese glazes and glazes. iron produce saturate ash bone at glaze I started with the of: 70f Red art Apple ash 30$ To this quality I next and to added add formula next add oxide of crystals To to be produce to the iron work formed rutile Hard-wood ash Kingman feldspar 5% to induce flux. additional percentages to increase iron I found ash best in the the glaze. of This addition saturate glaze. crystal glaze 35f 35$ glaze to five percent iron 5%$ causing iron at opalescent To this working from two content an I started with: 7. China Talc Clay 20$ 15$ 2$ 2$ Rutile Ilmenite In my testing wood have been ash I have found effective been added been used as as than a and silica to the glaze rutile the is to added may form rutile tributes titanium yellowish To halo for give source the rutile and ash 50$ 30$ 15$ Albany slip Cobalt Manganese Chrome oxide To produce of the feldspar, is Apple added as to add and act both contribute To to glaze additional The added. iron to oxide tan to brown coloring of Ilmenite also further glaze. This contributes and con a crystals. glaze. I started with: 1$ 1$ a apple ash and alumina, primarily used to has Clay .05$ this glaze, glaze. in the titanium manganese Custer feldspar Apple also a iron to the cobalt produce gives crystals. around The China flux. of is ash Kingman Feldspar has silica added hard-wood a crystals, rutile ilmenite have been and and is maple and ash develop former. rutile glaze wood ash. additional a to which alumina, in turn This glaze. ash glass of apple trying Talc has been magnesia color both fruit*wood and source formers. glass maple the flux a In tried. that the more as this formula, of provide is used as a high percentage contains some flux ash and iron and glass additional the magnesia. former. flux and major The of portion potash ash is Custer feldspar glass former. The 8. slip is Albany has both added high iron content a colorant cobalt contributes hue is formula chrome Cobalt oxide Manganese Iron oxide crystals in the contains lithium glaze spodwiiene .1$ 1$ mixture. as a to added glaze healer. and possibilities colorant which glazes, to apply ash glazes to easily clay will was The first consideration or powder glazing body formula for the once as cause flake they flaking. the glazes are The still combination to a another once is that the are applied third not problem fire, green, glaze the clay surface. off fire ware, when use oxides. ash It The and 1$ 10$ 1$ 20$ After formulating the me. feldspar of 20$ few color clay body. also form iron 15$ Lithium carb. Barium carb. the a the out 30$ 25$ 20$ Zercopax ashes is bring is: Iron a to glaze surface Spodumene Dolomite Kaolin are a This Apple ash Custer feldspar when manganese .5$ may be Spodumene faced greenish 30$ 15$ Albany slip wood A glaze. a manganese colorant cobalt As color. ash Custer feldspar of The oxide. The the to color the to It forming. glass is: Apple These blue. color blue-purple by the caused the for and clay contributes which provides deep a a as Secondly, pulled to bisque consideration tends as ware. deep into This is to prevent 9. stress cracks To When applying higher may be or from cracking The of the side one of piece then surface or spraying then stress By order using the the same is desired, surface opposite side by glazing both sides is to be which once fire ones am with strong formulate This such slips green ware a good once is special Flint silica AP Green fire clay Custer feldspar be low used once of I have and of clays fire body. composed for percentage strength. 30$ 15$ 5$ 30$ 3 to 5$ 5 to 8$ as may be applied. body to stoneware EPK Kyantitsue Grog glazed. methods high plasticity, presently working A9 White to be technique, glazing clay I by applied putting for the can If glazing only may be not one without Considerations I by glazing of water experimenting with many different kinds hope of percentage glazed and and mixture glaze surface other. which resist, in drying a the clay stop the flat to time glazing the wax are the off clay. double dipping, firing plates prevented the at piece the be can pottery dunking the on cracks the allow in needed flaking or bentonite to to flat glaze immediately of add glazes. flaking. or stress and will from powdering it is necessary to 3-5$ 5-7$ form uneven result the glaze keep surface, at which of: The from am shrinkage still which clay body I with 10. Some way in that be thicker walls is glaze The opment the form ash which glazes, of production an I have techniques, within the essence spirit and form with the line of be sharp alterations angle are fire stress glaze foot or enough glaze. In changes or leave This to be done. the chances for *s tress cracks able to production have been described oriented and of ash once glaze accessories. relate when green or its form. pottery. a to be piece of the pottery holds By combining the highly spirited, used developing technical abilities which produce techniques fire surface In my devel to draw myself closer to tried thrown freshly which should avoid the and once large a local slip glazes, beauty I leave the applying the while avoid for functional dinnerware these glazing during the ware, to while the are: upon reflected applied. procedures of try will pieces pieces onto where thickness extra the trimming the form to be elements the upon to hold surface developing and put When process. the to handle which will some the design of but closeness of I have found, yet saleable Ash Clays 1. Iron 2. Rutile crystal 3. Cobalt and 4. Spodumene 5. Formal 6. Closeup saturate Illustrations glaze glaze manganese glaze glaze dinnerwar^ placesetting using of double dipping glazes ash glazes ' "Top Pov-Hon 9 Z Ml II 0<i A r/> j***** i PC JUN 7 6 JU N 7 6 If.TBp P*r'*n 9 z Nfir ^ tOYi 3. Tap *Po*-+-'n Jf. Tp Po"r ttO\ ZNTlT 6c