RF-sputtering, sol-gel and ion

advertisement

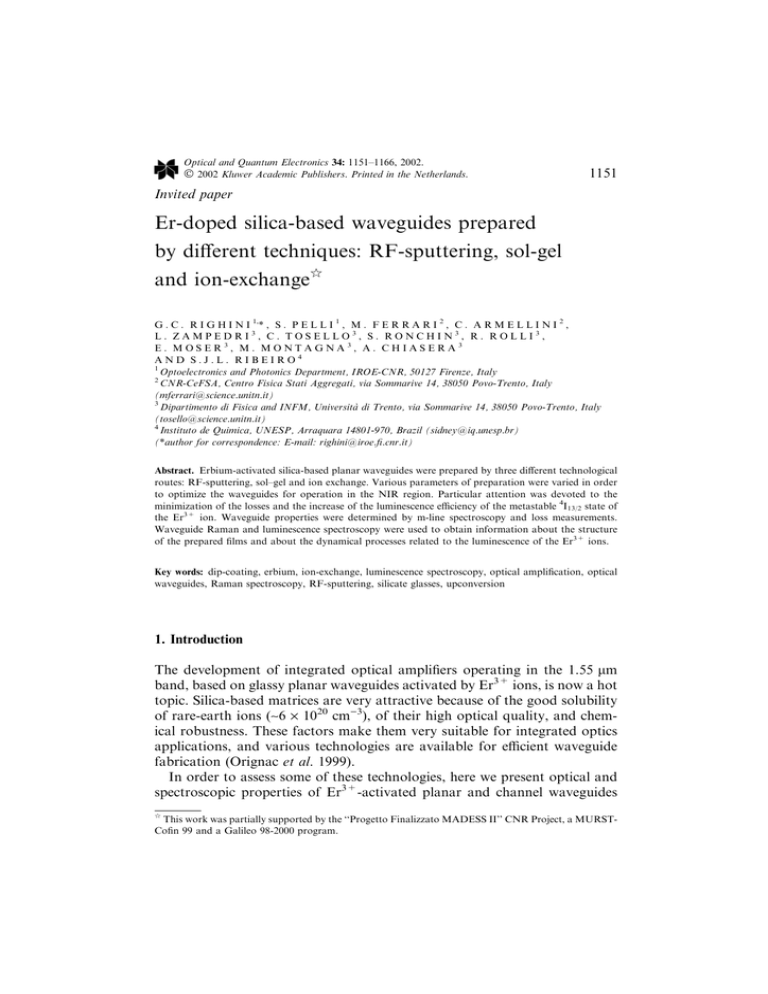

Optical and Quantum Electronics 34: 1151–1166, 2002. 2002 Kluwer Academic Publishers. Printed in the Netherlands. 1151 Invited paper Er-doped silica-based waveguides prepared by different techniques: RF-sputtering, sol-gel and ion-exchangeq G . C . R I G H I N I 1,* , S . P E L L I 1 , M . F E R R A R I 2 , C . A R M E L L I N I 2 , L. ZAMPEDRI3, C. TOSELLO3, S. RONCHIN3, R. ROLLI3, E. MOSER3, M. MONTAGNA3, A. CHIASERA3 AND S.J.L. RIBEIRO4 1 Optoelectronics and Photonics Department, IROE-CNR, 50127 Firenze, Italy 2 CNR-CeFSA, Centro Fisica Stati Aggregati, via Sommarive 14, 38050 Povo-Trento, Italy (mferrari@science.unitn.it) 3 Dipartimento di Fisica and INFM, Università di Trento, via Sommarive 14, 38050 Povo-Trento, Italy (tosello@science.unitn.it) 4 Instituto de Quimica, UNESP, Arraquara 14801-970, Brazil (sidney@iq.unesp.br) (*author for correspondence: E-mail: righini@iroe.fi.cnr.it) Abstract. Erbium-activated silica-based planar waveguides were prepared by three different technological routes: RF-sputtering, sol–gel and ion exchange. Various parameters of preparation were varied in order to optimize the waveguides for operation in the NIR region. Particular attention was devoted to the minimization of the losses and the increase of the luminescence efficiency of the metastable 4I13/2 state of the Er3+ ion. Waveguide properties were determined by m-line spectroscopy and loss measurements. Waveguide Raman and luminescence spectroscopy were used to obtain information about the structure of the prepared films and about the dynamical processes related to the luminescence of the Er3+ ions. Key words: dip-coating, erbium, ion-exchange, luminescence spectroscopy, optical amplification, optical waveguides, Raman spectroscopy, RF-sputtering, silicate glasses, upconversion 1. Introduction The development of integrated optical amplifiers operating in the 1.55 lm band, based on glassy planar waveguides activated by Er3+ ions, is now a hot topic. Silica-based matrices are very attractive because of the good solubility of rare-earth ions (~6 · 1020 cm)3), of their high optical quality, and chemical robustness. These factors make them very suitable for integrated optics applications, and various technologies are available for efficient waveguide fabrication (Orignac et al. 1999). In order to assess some of these technologies, here we present optical and spectroscopic properties of Er3+-activated planar and channel waveguides q This work was partially supported by the ‘‘Progetto Finalizzato MADESS II’’ CNR Project, a MURSTCofin 99 and a Galileo 98-2000 program. 1152 G.C. RIGHINI ET AL. prepared by three different technological routes: RF-sputtering (Tosello et al. 1999), sol–gel (Ferrari et al. 2000) and ion-exchange (Pelli et al. 2000). In the case of RF-sputtering and sol–gel techniques we fabricated planar waveguides based on the SiO2–TiO2 binary system. This composition, in fact, allows one to easily tailor the waveguide refractive index by changing the TiO2/SiO2 molar ratio. In the third case, we have first designed a silicate glass matrix suitable for ion exchange and we have then fabricated both planar and channel waveguides by diluted silver–sodium ion exchange. 2. Waveguide fabrication 2.1. RF-SPUTTERING SiO2–TiO2:Er3+ thin films were RF-sputtered on both vitreous (v)-SiO2 and silica-on-silicon (SOS) substrates. The SOS substrates were prepared by plasma-enhanced chemical vapor deposition (PECVD): a silica layer, 3.4 lm thick, was deposited on top of Si wafer, at a deposition rate of 105 nm/min. On these SOS substrates, a subsequent deposition of the erbium-activated silica–titania film was performed by sputtering a target disk of silica (100 mm diameter) on which eight disks of TiO2 (10 mm diameter) and a metallic erbium wire (2 mm diameter, 26 mm total length) were put. The residual pressure in the sputtering chamber, before deposition, was about 2 · 10)7 mbar. Substrates were not heated during the process. However, in order to prevent cracking, microfractures or bad cohesion between the waveguiding film and the substrate, the SOS substrates were annealed at 600C before the film deposition (Tosello et al. in press). The sputtering was carried out with an Ar gas at a pressure of 7 · 10)3 mbar and the applied RF power was 150 W with a reflected power of 18 W. The deposition time was of 3 h 30 m in order to have the appropriate thickness for supporting one mode at 1.5 lm. The same parameters were employed for film deposition onto vSiO2 substrates. It has to be remarked that the as-prepared films did not support any guided mode because of non-stoichiometric structure of SiOx with x < 2; a thermal annealing in air for 6 h at 600C was necessary to achieve light propagation (Tosello et al. 1999, in press). Table 1 reports the oxygen, silicon, titanium and erbium atomic concentration obtained by energy dispersive spectrometry (EDS) for the waveguide deposited on the v-SiO2 substrate. 2.2. SOL–GEL Figure 1 describes the sol–gel process for the preparation of the waveguides. The starting solution was obtained by mixing tetraethylorthosilicate (TEOS), 1153 Er-DOPED SILICA-BASED WAVEGUIDES Table 1. Atomic concentration of the components of the waveguide deposited on v-SiO2 substrate obtained by EDS measurement Element Concentration (at.%) O Si Ti Er 65.2 30.6 3.5 0.7 The estimated error is 10%. ethanol, deionized water and hydrochloric acid as a catalyst. Titanium isopropoxide (TiPOT) was used as TiO2 precursor. As TEOS and TiPOT have very different hydrolysis rates, TEOS was first pre-hydrolyzed for 1 h at 65C before adding TiPOT solution. The final solution was let react under stirring for 16 h at room temperature. Silica–titania films were obtained by dip-coating, with a dipping rate of 40 mm/min, using cleaned pure v-SiO2 slabs (n ¼ 1.46 at 632.8 nm) as Fig. 1. Flow diagram of the sol–gel process used for the preparation of erbium-activated SiO2–TiO2 planar waveguides. 1154 G.C. RIGHINI ET AL. substrates. After each deposition, the films were annealed in air at 700C for 2 min. A sufficient thickness to obtain a guiding layer was achieved by alternating a number of deposition and heat-treatment steps. A cycle of 10 depositions was necessary to obtain monomode waveguides at 632.8 nm, with thickness of 0.5 lm. 2.3. ION-EXCHANGE The base glass designed for ion-exchange was of soda-lime type, with approximate composition 73SiO2, 14Na2O, 11CaO, 1Al2O3, 0.4P2O5, 0.6K2O (mol%). Glass was produced by melting reagent-grade oxides (approximately 650 g for each batch). Several samples were produced in different batches, by adding different quantities of Er2O3 and Yb2O3, with rare-earth concentrations ranging from 0.3 to 0.8 mol%. The samples were then cut in 35 mm · 25 mm · 1 mm plates and optically polished on one side. Planar and channel waveguides were subsequently obtained by immersing the slides into a molten salt containing 0.5AgNO3 and 99.5NaNO3 mol% at 325C. For channel waveguides, an Al masking layer and conventional photolithography process were used. Their typical size was 7–13 lm width and about 3 lm depth. 3. Results and discussion 3.1. OPTICAL PROPERTIES The refractive index and the thickness of the various waveguides were measured by an m-line apparatus. The resolution in the determination of the angles synchronous to the propagation modes was 0.0075, giving an error on the effective index of about 0.0005. Total propagation losses were measured by collecting the light intensity scattered out of the waveguide plane. As usual, the measured intensity along the guided light streak was fit to an exponential decay function, assuming a homogeneous distribution of the scattering centers in the waveguide. In all cases only the fundamental TE0 mode of the waveguide was excited. Scattered light was usually collected by a video camera; however, loss measurements at 1.5 lm were also made by using a scanning optical fiber coupled to a Ge detector. In the latter case, the light was injected in the waveguide from a laser emitting at 1550 nm. 3.1.1. RF sputtering Table 2 reports the optical parameters measured for the planar waveguides produced by RF-sputtering. 1155 Er-DOPED SILICA-BASED WAVEGUIDES Table 2. Optical parameters of the SiO2–TiO2:Er3+ planar waveguides prepared by RF-sputtering Substrate Number of modes at 632.8 nm Number of modes at 1550 nm Film thickness (lm) Refractive index at 632.8 nm Attenuation coefficient at 632.8 nm (dB/cm) Attenuation coefficient at 1550 nm (dB/cm) SOS v-SiO2 3 1 2.5 1.503 1.4 0.9 3 1 2.5 1.508 0.7 0.7 The loss values at the two wavelengths may appear not fully consistent. Two remarks, however, have to be done: (a) loss measurements at the two wavelengths are made by using techniques (video camera and scanning fiber, respectively) which have slightly different accuracy; (b) the absorption peak of erbium is at 1532 nm, so that the measurement at 1550 nm only partially takes into account erbium absorption. In any case, we can conclude that scattering losses of these waveguides at 1.5 lm are very low. The refractive index profile of a typical sputtered waveguide is shown in Fig. 2. From the equivalence of the refractive index profiles obtained for TE and TM modes it appears that the birefringence in these waveguides is negligible. Fig. 3 shows the squared electric field profiles of the TE0 mode of the SOS waveguide, calculated at 632.8 and 1550 nm by using the parameters obtained by the m-line measurements. The ratio of the integrated intensity, i.e. the ratio between the field intensity in the guiding film and the total intensity, which includes also the squared evanescent fields, is 0.99 and 0.89 at 632.8 and 1550 nm, respectively. Fig. 2. Refractive index profiles, of a SiO2–TiO2:Er3+ planar waveguide prepared by RF-sputtering on an SOS substrate, reconstructed from modal measurements at 632.8 nm for (a) the TE and (b) TM polarization. The effective indices of the TE (d) and TM (j) modes are reported. 1156 G.C. RIGHINI ET AL. Fig. 3. Calculated squared electric field profiles of the TE0 mode at 632.8 nm (a) and 1550 nm (b) across the layered structure, air clad (c), guiding film (w) and SiO2 substrate (s), of the SiO2–TiO2:Er3+ planar waveguide prepared by RF-sputtering on an SOS substrate. These ratios indicate that an efficient injection at 1550 nm is possible for this waveguide. 3.1.2. Sol–gel So far, by sol–gel route we produced SiO2–TiO2:Er3+ planar waveguides with typical thickness of 0.5 lm only. These films therefore support only one propagating mode at 632.8 nm: their attenuation coefficient is 0.5 dB/cm, indicating a quite good uniformity and overall optical quality. The refractive index is about 1.58 at 632.8 nm, and their confinement factor (still at 632.8 nm) is about 0.85. The preparation of thicker waveguides, supporting a propagation mode at 1550 nm, is now in progress. 3.1.3. Ion-exchange As expected, ion-exchanged waveguides present a gradient-index profile; a typical curve, well approximated by an erfc function, is shown in Fig. 4. The index difference between surface index and substrate index, Dn, is around 0.04. Propagation loss of planar waveguides supporting a single mode at 1.5 lm (and three modes at 632.8 nm) was less than 0.4 dB/cm at 633 nm, around 0.3 dB/cm at 840 nm, and in the range 3–4 dB/cm, depending on Er3+ concentration, at 1.5 lm. These losses were measured by using a vidicon camera. Channel waveguides, fabricated by conventional photolithography, exhibit higher propagation losses. In order to decrease them, a purely thermal annealing was tested: it was found that a 50 min annealing at 320C in air was sufficient to lower losses down to 3 dB/cm at 1.5 lm (as in planar waveguides) from a value higher than 8 dB/cm measured just after the exchange. Er-DOPED SILICA-BASED WAVEGUIDES 1157 Fig. 4. A typical reconstructed index profile: (a) TE and (b) TM polarization. 3.2. SPECTROSCOPIC CHARACTERIZATION A waveguide configuration was used for both Raman and photoluminescence measurements. Raman spectra were collected in VV polarization by exciting the TE0 mode with an Ar laser, operating at 457.9 or 514.5 nm, and detecting the scattered light, polarized perpendicular to the direction of propagation, from the front of the waveguide. The signal was selected by a double monochromator and analyzed by a photon-counting system. Photoluminescence spectroscopy, in the region of the 4I13/2 fi 4I15/2 transition of Er3+ ions, was performed using the 514.5 nm line of an Ar laser as the excitation source. The luminescence was dispersed by a 320 mm singlegrating monochromator with a resolution of 2 nm. The light was detected using a InGaAs photodiode and lock-in technique. Decay curves were obtained recording the signal by a digital oscilloscope. 3.2.1. RF sputtering The Raman spectra of the v-SiO2 substrate (Fig. 5(a)) and of the silica– titania guiding film (Fig. 5(b)) deposited on that substrate were collected in VV polarization, in a 90 geometry, by exciting the TE0 mode with an Ar laser operating at 457.9 or 514.5 nm and detecting the scattered light, polarized parallel to that of the exciting beam, from the front of the waveguide. The former figure clearly shows Raman bands at about 60, 440, 490, 600, 800, 1060 and 1190 cm)1, characteristic of the silica network (Galeener 1979). The bands in the region above 200 cm)1 correspond to optical phonons, and the band at 60 cm)1 is the boson peak, characteristic of the disordered glassy structure. The Raman spectrum of the silica–titania waveguide, in the latter figure, shows bands at about 50, 440, 490, 600, 800, 920, 1090 and 1190 cm)1, respectively. This spectrum is similar to those reported for SiO2–TiO2 glasses with titanium oxide content in the range 3–12 mol% (Bihuniak and Condrate 1981; Best and Condrate 1985; Chmel et al. 1992). 1158 G.C. RIGHINI ET AL. Fig. 5. Raman spectra of a v-SiO2 substrate (a) and of the SiO2–TiO2:Er3+ planar waveguide prepared by RF-sputtering on the v-SiO2 substrate (b), collected in the VV polarization by exciting at 457.9 nm. The excitation of the waveguide is in the TE0 mode. By comparing the Raman spectra of the silica–titania waveguide with that of the fused silica the more evident differences are: (i) the appearance of the Raman bands at 920 cm1 and at 1090 cm1 , due to the vibrations of mixed Si–O–Ti linkage (Bihuniak and Condrate 1981; Best and Condrate 1985; Chmel et al. 1992); (ii) a shift to lower frequencies of the boson peak and (iii) a decrease of the intensity of the defect bands D1 and D2 centered at 490 and 600 cm1 . The strong intensity of the Si–O–Ti bands, compared to the intensity of the Si–O–Si band at 800 cm1 , is indicative of a good intermingling of the two components of the films. Raman structures due to crystalline phases of TiO2 are not observed. The step-like refractive index profiles together with the Raman measurements suggest an essentially homogeneous structure of the waveguides, with a network consisting of intermingled TiO4 and SiO4 units. The fluorescence spectrum of the 4I13/2 fi 4I15/2 transition of the Er3+ ion is characterized by a spectral width of about 45 nm (Fig. 6). The fluorescence decay curve has single exponential profile; no changes in the decay curve and in the shape of the 4I13/2 fi 4I15/2 transition were observed for powers up to 300 mW. The measured lifetime of 3.7 ms of the 4I13/2 metastable level seems to be short if compared to that of 14 ms calculated for silicate glasses on the basis of the Judd–Ofelt theory (Hehlen et al. 1997). However, since, at our knowledge, no values of the radiative lifetime for the metastable 4I13/2 in SiO2–TiO2 host are available in the literature, it is hazardous to estimate the quantum efficiency. We can just compare this lifetime with the measured values reported for erbium-activated silica–titania planar waveguides produced by sol–gel route. Orignac et al. (1999) reported a measured lifetime of about 3 ms for the fluorescence lifetime of the 4I13/2 Er-DOPED SILICA-BASED WAVEGUIDES 1159 Fig. 6. Room temperature photoluminescence spectrum of the 4I13/2 fi 4I15/2 transition of Er3+ ion, obtained by exciting the TE0 mode at 514.5 nm. This spectrum refers to a SiO2–TiO2:Er3+ planar waveguide prepared by RF-sputtering on SOS substrate. state in a planar waveguide of composition 80SiO2–20TiO2–5Al2O3 activated by 0.7 at.% of erbium. On the other hand, Yeatman et al. (1999) measured a lifetime of about 8 ms in strip-loaded waveguides of composition 93SiO2– 7TiO2–5Al2O3 with ratios Er/(Si + Ti) ranging from 0.1 to 0.5 mol%. It is possible to attribute the shorter lifetimes measured in silica–titania waveguides to larger distortions of the Er3+ site in some silica–titania matrices than in others or in pure silica. However, we cannot exclude that energy transfer processes could also contribute to reduce the lifetime. In fact recent modeling by molecular dynamics simulations on erbium-activated silica–titania glass (8.5 at% Ti/Si, 2.3% Er/Si) have shown that more than 55% of Er3+ ions belong to pairs or clusters of higher size (Chaussedent et al. 2000). 3.2.2. Sol–gel The main factors affecting the performance of sol–gel-based waveguides are the non-radiative relaxation channels due to rare-earth concentration quenching and to vibration of the OH groups. The OAH stretching vibration affects the fluorescence decay at 1.5 lm because two OAH vibrations are enough to bridge the gap of about 6500 cm1 between the ground state 4I15/2 and the first excited state 4I13/2 of the Er3+ ion (Hehlen et al. 1997; Duverger et al. 2001). Therefore, the sol–gel process has to be carefully controlled in order to minimize the residual OH content and to obtain the largest dispersion of Er3+ ions. Fig. 7 shows the Raman spectra of some undoped 80SiO2–20TiO2 planar waveguides, submitted to different annealing processes. The observed bands are typical of the silica–titania binary system as already discussed in the case of the planar waveguides prepared by RF-sputtering technique. However, in 1160 G.C. RIGHINI ET AL. Fig. 7. Room temperature Raman spectra obtained in VV polarization by exciting at 514.5 nm the TE0 mode of undoped 80SiO2–20TiO2 planar waveguides. Spectra refer to waveguides produced by different thermal treatments: (a) intermediate annealing (2 min at 700C at every deposition); (b) intermediate annealing plus final annealing at 800C for 2 m 30 s; (c) intermediate annealing plus final annealing at 800C for 5 m 30 s; (d) intermediate annealing plus final annealing at 900C for 2 m. the case of the sol–gel films we can note the additional presence of the broad band with the maximum at about 3560 cm1 , which is due to molecular water and SiAOH groups (Duverger et al. 2001). The Raman spectra of Fig. 7(b)–(d) were obtained for waveguides processed with the same intermediate thermal treatment of 700C for 2 min at every deposition but with different final thermal annealing. By increasing the annealing temperature, the intensity of the band assigned to the OH groups decreases. Furthermore, Raman structures appear in the region between 150 and 350 cm1 . They are attributed to devitrification of the silica–titania film. Further increases of either the temperature or the annealing time produce an increase of the intensity of the Raman peaks due to crystallization, and the typical structures of the anatase phase appear. Therefore, high temperature annealing lowers the OH content, but increases the losses by scattering from the titania nanoclusters. The best compromise was obtained for a final thermal annealing of 2 min at 900C and a molar ratio H2O/TEOS ¼ 2. Earlier studies showed that the degree of heterocondensation, measured by the number of Ti–O–Si linkages, is maximum for 20 mol% TiO2 corresponding to the minimum phase separation (Orignac and Almeida 1996; Almeida 1998). However, for 20TiO2–80SiO2 films, we were not able to avoid devetrification after the thermal annealing necessary for full densification. Furthermore we observed that in presence of devitrification the decay of the metastable state 4I13/2 exhibits a non-single exponential profile with short lifetime. Thus, in order to reduce the devitrification and increase the dispersion of the erbium, we reduced the titania content without changing the other parameters of deposition and densification. Er-DOPED SILICA-BASED WAVEGUIDES 1161 Fig. 8 shows the room temperature photo-luminescence spectrum corresponding to the 4I13/2 fi 4I15/2 transition of the Er3+ ions in a 93SiO2–7TiO2 planar waveguide activated by 1 mol% Er/(Si+Ti). The spectral width of the emission band, measured at 3 dB from the maximum of the intensity, was 51 ± 2 nm. Fig. 9 shows the decay curve of the luminescence from the 4I13/2 metastable state of the Er3+ ions in the same waveguide. The profile is single exponential with a lifetime of about 7 ms. This relatively long lifetime can be considered Fig. 8. Room temperature luminescence spectrum of the 4I13/2 fi 4I15/2 transition of Er3+ ions for a 93SiO2–7TiO2 planar waveguide, prepared by sol–gel route, activated by 1 mol% Er/(Si + Ti). Excitation at 514.5 nm in the TE0 mode. Fig. 9. Room temperature decay of the luminescence from the 4I13/2 metastable state of the Er3+ ions for a 93SiO2–7TiO2 planar waveguide activated by 1 mol% Er/(Si + Ti). Excitation at 514.5 nm in the TE0 mode. 1162 G.C. RIGHINI ET AL. good enough for devices development, and is comparable with the already mentioned value of 8 ms measured by Yeatman et al. who also demonstrated a signal enhancement up to 1 dB/cm (Yeatman et al. 1998, 1999). Even by comparing our value of 7 ms with that of 14 ms calculated for silicate glasses on the base of the Judd–Ofelt theory (Hehlen et al. 1997), a quantum yield of at least 50% can be inferred. We, however, as already discussed, estimate that the true quantum yield would be higher. In fact, the presence of the titania at the local site of the Er3+ ion can increase the oscillator strength and significantly decrease the radiative lifetime. Further measurements are therefore necessary to clarify this point. Finally, we did not observe any change in the spectral shape of the 4 I13/2 fi 4I15/2 transition and in the decay profile of the luminescence from the 4I13/2 state by varying the excitation power up to 120 mW. 3.2.3. Ion-exchange The Raman spectra of the ion-exchanged planar waveguides showed that the silver ions, which have higher mass and polarizability than sodium ions, modified the Raman activity of the vibrational modes and in particular the SiAO stretching modes (Montagna et al. 2000). High-resolution spectra were taken in order to study in detail the low frequency part of the spectra. The low frequency vibrational band of the silver nanoparticles was isolated from the Raman spectrum of the surrounding glass by a subtraction of the Raman spectrum of the substrate. This procedure assumes that the Ag+ content of the exchanged glass does not dramatically influence the line shape and intensity of the boson peak, the low frequency contribution of Raman scattering of the glass. The result of this subtraction is shown in Fig. 10 for the TE0 mode. Fig. 10. Room temperature low frequency Raman spectrum for a silver-exchanged soda-lime waveguide obtained by excitation of the TE0 mode at 514.5 nm. Er-DOPED SILICA-BASED WAVEGUIDES 1163 The band is attributed to l ¼ 2 spheroidal vibrations of a spherical nanocluster (Ferrari et al. 1996). Its frequency is proportional to the inverse cluster diameter: x2 ¼ 0:85 Vt dc where Vt is the transverse sound velocity, d is the diameter of the spherical particle and c is the speed of light. Its bandwidth is partly due to homogeneous broadening, but mainly to the size dispersion of the nanoparticles (Montagna and Dusi 1995). Taking Vt ¼ 1660 m/s, a value averaged on the different directions in the crystal (Fujii et al. 1991), from the TE0 spectrum of Fig. 10 we can deduce a mean cluster size of about 1.3 nm, with a large size dispersion for the region near to the surface. Low-frequency Raman measurements were repeated by selectively exciting different TEm modes and confirmed this finding. Such silver cluster size, fortunately, is not large enough to appreciably influence the optical properties of the waveguides in the NIR region. Absorption spectra indicated, as expected, a significant increase of the absorption at 980 nm in the Er/Yb-co-doped waveguides with respect to Erdoped ones. In both types of waveguides, however, the bandwidth of the 4 I13/2 fi 4I15/2 transition of the Er3+ ion was measured to be about 20 nm. The luminescence decay profiles were well fitted by a single exponential curve, and measured lifetimes ranged from 6 to 8 ms in all the samples, depending on rare-earth concentrations. The corresponding radiative lifetimes were in the range 12.2–14.5 ms, calculated for a glass co-doped with 3 wt.% Er and 5 wt.% Yb and for a glass with 3 wt.% Er only, respectively. Thus, one can estimate a quantum yield between 50 and 55%. Preliminary optical gain measurements were made in channel waveguides by using an input signal of about 1 mW in the waveguide (much larger than the fraction of lW which is used in the small-signal-approximation measurements); as expected in this case, no net gain was detected, but signal enhancement of the order of 0.4 dB/cm in Er-doped waveguides and larger than 2.5 dB/cm in Er3+/Yb3+ co-doped waveguides was measured, at pumping powers of about 60 mW. Very recent measurements in the smallsignal-approximation, in fact, have proved that a net optical gain higher than 1 dB/cm is reachable. 4. Conclusions Erbium- and erbium/ytterbium-activated silica-based optical waveguides were produced by three different technologies: RF-sputtering, sol–gel and 1164 G.C. RIGHINI ET AL. ion-exchange. The first two routes allowed us the deposition of the active layers onto vitreous silica or SOS substrates, the latter one being more convenient for multi-functional optoelectronic integration. In our case ion exchange implied the use of rare-earth-doped bulk glass substrates, but this is not a strict limitation. Fick et al. (2000), for instance, already demonstrated the possibility of defining channel waveguides by ion-exchange in a Na-rich sol–gel film. The comparison among the three technological processes leads to the following remarks: (a) Silica–titania RF-sputtered waveguides: As-deposited films containing 0.7 at.% erbium did not support guided light propagation, but after thermal annealing in air for 6 h at 600C well confined TE and TM modes were visible. Propagation losses of 0.7 and 0.9 dB/cm were measured at 1550 nm for waveguides deposited on v-SiO2 and SOS substrates, respectively. Scattering losses were higher in the latter case, due to the surface roughness of the film which replicates that of the buffer layer. The reconstructed refractive index profiles and the Raman measurements indicated that the films are homogeneous with a network consisting of intermingled silica–titania units. As to spectroscopic properties, on can note the wide fluorescence band around 1532 nm (45 nm FWHM), while the lifetime of 3.7 ms is not very long, even if sufficient for optical amplification and lasing applications. (b) Silica–titania sol–gel waveguides: Multi-layered films were necessary to obtain the proper thickness for an optical waveguide in the visible and NIR. Layers were deposited by dip-coating, with an intermediate annealing of 2 min at 700C at every deposition. The best compromise between high densification of the film, i.e. low OH content, and low losses was obtained for a molar ratio H2O/TEOS ¼ 2 and a final thermal annealing of 2 min at 900C. After several tests, we found that a good composition was 93SiO2– 7TiO2: in such a case, a guide activated by 10 000 ppm Er/(Si + Ti) exhibited quite good spectroscopic characteristics, namely a wide bandwidth of 51 nm (FWHM) and a long lifetime of 7 ms. (c) Ion-exchanged waveguides in silicate glasses: High-quality optical waveguides were produced by diluted silver ion-exchange in Er- and Er/Ybdoped silicate glasses. In planar waveguides losses were less than 0.4 dB/cm at 633 nm; in channel waveguides, on the other hand, a thermal annealing in air was necessary in order to keep losses lower than 3 dB/cm at 1532 nm (namely at the absorption peak of erbium). The fluorescence bandwith (FWHM) is around 20 nm, independently on the rare-earth concentration, while the lifetime of the excited state can vary between 6 and 8 ms in the differently doped samples. As an overall assessment, we can conclude saying that all three techniques have a high potential for the development of integrated optical amplifiers and Er-DOPED SILICA-BASED WAVEGUIDES 1165 lasers, even if they can be considered to be at different stages: RF-sputtering seems to be the one that gives more lossy waveguides than the other ones (and, in our case at least, shorter lifetimes), while sol–gel technology is the most flexible one, but still requires deep investigation in order to exploit all its potential. Ion-exchange, on the other hand, is the most mature technology, and its major disadvantage is in the limited capability of integration with silicon-based devices. Sputtered and sol–gel waveguides also seem more suitable for optical amplifiers to be used in WDM systems, due to their wide bandwidth, while ion-exchanged ones may be more convenient for integrated optical lasers. So far, we have been able to test for optical gain only the ion-exchanged waveguides, and a net optical gain higher than 1 dB/cm was measured very recently in Er/Yb-co-doped samples. Further tests are now in progress to measure gain properties of all the three types of waveguides. Acknowledgments The authors wish to thank Massimo Brenci (IROE) and Gualtiero Nunzi Conti (Optical Sciences Center) for useful discussions. The technical help of Roberto Calzolai (IROE) to cut and polish samples is also gratefully acknowledged. References Almeida, R.M. J. Sol–Gel Sci. Technol. 13 51, 1998. Best, M.F and R.A. Condrate. J. Mat. Sci. Lett. 4 994, 1985. Bihuniak, P.P and R.A. Condrate. J. Non-Cryst. Solids 44 331, 1981. Chaussedent, S., C. Bernard, A. Monteil, N. Balu, J. Obriot, S. Ronchin, C. Tosello and M. Ferrari. In: Rare-Earth Doped Materials and Devices IV, ed. S. Jiang, Proceedings of SPIE, SPIE, Bellingham, Washington, USA, 3942 243, 2000. Chmel, A., G.M. Eranosyan and A.A. Kharshak. J. Non-Cryst. Solids 146 213, 1992. Duverger, C., M. Montagna, R. Rolli, S. Ronchin, L. Zampedri, M. Fossi, S. Pelli, G.C. Righini, A. Monteil, A. Armellini and M. Ferrari. J. Non-Cryst. Solids 280 261, 2001. M. Ferrari, et al. J. Sol–Gel Sci. Technol. 19 569, 2000. Ferrari, M., F. Gonella, M. Montagna and C. Tosello. J. Appl. Phys. 79 2055, 1996. Fick, J., A. Martucci and M. Guglielmi. J. Sol–Gel Science Technol. 19 573, 2000. Fujii, M., T. Nagareda, S. Hayashi and K. Yamamoto. Phys. Rev. B 44 6243, 1991. Galeener, F.L. Phys. Rev. B 19 4292, 1979. Hehlen, M.P., N.J. Cockroft, T.R. Gosnell and A.J. Bruce. Phys. Rev. B. 56 9302, 1997. Montagna. M and R. Dusi. Phys. Rev. B 52 10080, 1995. Montagna, M., S. Ronchin, F. Rossi, C. Tosello, E. Moser, M. Ferrari and G.C. Righini. Proceedings of SPIE 3942 224, 2000. Orignac, X and R.M. Almeida. IEE Proc.-Optoelectron. 143 287, 1996. Orignac, X., D. Barbier, X.M. Du, R.M. Almeida, O. McCarthy and E. Yeatman. Opt. Mater. 12 1, 1999 and references therein. 1166 G.C. RIGHINI ET AL. Pelli, S., M. Brenci, M. Fossi, G.C. Righini, C. Duverger, M. Montagna, R. Rolli and M. Ferrari. RareEarth Doped Materials and Devices IV, ed. S. Jiang, Proceedings of SPIE, 3942 139, 2000. Tosello, C., S. Ronchin, E. Moser, M. Montagna, P. Mazzoldi, F. Gonella, M. Ferrari, C. Duverger, R. Belli and G. Battaglin, Phil. Mag. B 79, 2103, 1999. Tosello, C., F. Rossi, S. Ronchin, R. Rolli, G.C. Righini, F. Pozzi, S. Pelli, M. Fossi, E. Moser, M. Montagna, M. Ferrari, C. Duverger, A. Chiappini and C. De Bernardi. J. Non-Cryst. Solids (in press). Yeatman, E.M., M.M. Ahmad, O. McCarthy, A. Vannucci, P. Gastaldo, D. Barbier, D. Mongardien and C. Moronvalle. Opt. Commun. 164 19, 1999. Yeatman, E.M., K. Pita, M.M. Ahmad, A. Vannucci and A. Fiorello. J. Sol–Gel. Sci. Technol. 13 517, 1998.