The Tender Specification

advertisement

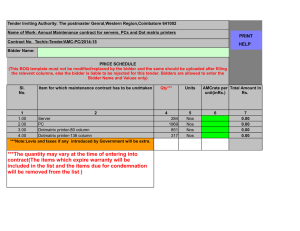

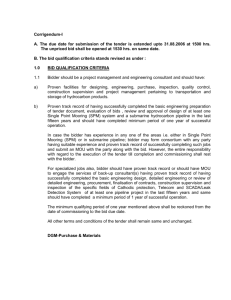

MEGHALAYA POWER GENERATION CORPORATION LIMITED Office of the Superintending Engineer, Generation Circle-I Umiam: 793103. Phone No:- 0364 - 2570515 Mobile No. 9612170906 Email :- segen.umiam@gmail.com Tender No--MePGCL/SE(GC-1)/ T-70/2015/1 Dated 3rd March, 2015 TENDER SPECIFICATION FOR MANUFACTURE & SUPPLY OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM - UMTRU STAGE-IV POWER STATION, NONGKHYLLEM Price: 3000.00 Date of Opening 10/04/2015 MEGHALAYA POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2(Two) NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS 1.0 SCOPE : Scope of work covered under the package includes design, engineering, manufacture, testing, supply, insurance and transportation to Site, 2 Nos of Dry Type (Cast Resin) Excitation Transformers for Umiam-Umtru Stage-IV Power Station. The scope given above is only indicative. The detailed scope has been described in the later part of the bidding documents. 2.0 Responsiveness of Bid To be eligible for the Tender Evaluation Process stage as described as in Clause 3.0 below , the Tenders should be initially found responsive. For the Tender to be responsive, compliance of the requirements as prescribed in Clause 5.0 (Bid Responsiveness) should be observed by the Bidders. Non Compliance will result in Bid being declared Non Responsive resulting in outright rejection. 3.0 Tender Evaluation Process The Tender will be evaluated on Quality and Cost Based Analysis (QCBS) System where the Techno Commercial Bid and the Price Bid shall be evaluated on Points as follows:i. A weightage of 70 % shall be given to the Techno- Commercial component of the Bid and 30 % weightage shall be given to the price/cost component of the Bid. ii. a) Responsive Bidders must obtain a fixed minimum qualifying marks in techno commercial Bid to be eligible for opening and scrutiny of their Price Bid. b) Failure to obtain the minimum qualifying Marks in techno commercial though the Bid is responsive, will render the bidder ineligible for price bid opening. c) The set minimum marks to be obtained in the techno-commercial Bid is 70 marks. iii 4.0 As per clause 10 of Technical Specification(Part I) QUALIFYING REQUIREMENTS OF BIDDERS To qualify for the contract, the manufacturer/ Authorised dealer must meet the following minimum criteria and also as per Clause 3 of Technical Specification(Part I):4.1 The Bidder should have designed, manufactured tested and supplied Dry Type Cast Coil Resin Excitation Transformer for Excitation systems of Hydro Power Stations, which are in successful operation for at least 5 (five) years as on the date of issue of NIT. 4.2 The Bidder must have designed, manufactured; type tested and supplied Dry Type Cast Resin Excitation Transformer for Excitation systems of Hydro Power Stations for minimum period of 3(three) years . The Bidders should have carried out Type Test certified by CPRI/National Test Houses. 2 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS 4.3 The Bidder should have manufactured Dry Type Cast Resin Excitation Transformer for Excitation systems of Hydro Power Stations, minimum of last 3 years. 4.4 The Bidder should have supplied such Transformers to other SEBs, Energy Corporations, Central Govt Utilities or Other Utilities. 4.5 The average annual turnover of the manufacturer for the three best financial years out of last three financial years, at minimum should be Rs 1.0 Crores (Rupees one Crores) 4.6 The bidder should have all In house Testing facilities for carrying out all the routine test as per IS:1180 and IS : 2026 with latest amendments. 4.7 The Manufacturer must provide a guarantee of 24 months from the date of receipt at the Stores OR 12 months from the date of commissioning , whichever is earlier. 5.0 BID RESPONSIVENESS 5.1 For Determining the Responsiveness/Eligibility of the Bid, detailed Documents wherever necessary, are to be submitted along with the Part –I (Techno-commercial Bid) as under :- a) An Earnest Money Deposit of Rs 1.0 Lakh (Rupees One Lakh) only in the form of a Bank Guarantee from a Nationalised Bank as per Annexure-A is to be submitted in a separate Envelope in Favour of “MePGCL, Principal Account, Shillong”. b) Period of validity of the Bid. c) Agreement to the Terms of Payment as per Clause 21.0 d) Agreement to the Delivery Schedule as per Clause 14.0 e) Guaranteed Technical Particulars for the Specified ratings of Excitation Transformers. f) Copies of Type Test Certificates from National Test Houses. g) Details of Orders executed for specified ratings of Excitation Transformers for the last three years. h) Quality Assurance Plan. i) Performance Certificate from Users. j) Proof of having manufactured and supplied at least 30 nos. of Excitation Transformers. k) Upto-date Income Tax Clearance Certificate. l) Audited Documents relating to annual turnover m) As per Clause 13.1 of Technical Specification(Part I) 5.2 The following additional documents are required to be submitted with the Bid. a) BIS/ISO Certificates. b) Warranty . In addition to the above requirements, the MePGCL reserves the right to request for any additional information and also reserves the right to reject the proposal of any Bidder, if in the opinion of the MePGCL, the qualification data is incomplete. 6.0 COST OF BIDDING The Bidder shall bear all the costs and expenses associated with preparation and submission of its Bid including technical and other presentation etc. The MePGCL shall in no case be responsible or liable for those costs, regardless of the conduct or outcome of the bidding process. 3 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS 7.0 CLARIFICATIONS ON BIDDING DOCUMENTS If the prospective Bidder finds discrepancies or omissions in the specifications and documents or is in doubt as to the true meaning of any part, the bidder shall at least 10 days before the bid opening make a request in writing for any interpretation /clarification. After receipt the clarification, the Bidder may submit his Bid but within the time and date as specified in the Invitation for Bids. All such interpretations and clarifications shall form part of the Bidding Documents and shall accompany the Bidder’s proposal. The MePGCL shall respond in writing to any request for such clarification of the Bidding Documents. Written copies of the response (including an explanation of the query but without identifying its source) shall be sent to all prospective bidders, which have received the Bidding Documents. The same shall also be posted in the Web Site. 8.0 9.0 AMENDMENT TO BIDDING DOCUMENTS 8.1 At any time prior to the deadline for submission of bids, the MePGCL may, for any reason, whether on its own or in response to a clarification requested by a prospective Bidder, modify the Bidding Documents by amendment (s). 8.2 In order to afford prospective bidders reasonable time in which to take the amendment into account in preparing their bids, the MePGCL may, at its discretion, extend the deadline for submission of bids. 8.3 Such amendments, clarifications etc shall be binding on all bidders and shall form part of the bid documents. DOCUMENTS COMPRISING THE BID 9.1 The Bid shall be submitted in 2 (two) parts (Part-I & Part-II) in separate sealed envelopes properly super scribed as follows: 9.2 Part-I: EMD (in a separate Envelope) & Techno-Commercial Bid Document The EMD along with the Techno Commercial bids are to be submitted separately under two separate sealed envelopes super scribing tender no, name of bidder, due date, etc :Envelope 1 : Containing the EMD Envelope 2 : Techno-Commercial bid. These two envelopes shall be kept inside one envelope marked Part-I wherein the tender no. & name of the bidder are also superscribe. 9.3 Part-II: Containing Price Bid Document as per format in Annexure V The price bid should distinctly indicate the following components: – Quoted price with clear differentiation of Ex-factory price, Freight & Insurance and Taxes and Duties. 10.0 9.4 Price bids are to be submitted in a separately sealed envelope superscribing tender no. and name of the bidder. 9.5 Envelopes containing Part I & Part II are to be kept inside a single envelope superscribing tender no. and name of the bidder. SCOPE OF THE PROPOSAL 10.1 The scope of the proposal shall be on the basis of a single Bidder’s responsibility, completely covering all the equipment specified under the accompanying Technical Specification (Part I). It shall include the following: a. Detailed design of the equipment as applicable. 4 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS b. Stage Inspection & Pre-delivery Inspection shall be carried out by the MePGCL after approval of Drawings. The manufacturer is to issue the Inspection call. c. Complete manufacture including shop testing. d. Providing engineering drawing, data, operation, manual, etc. e. Arrangement for pre-delivery inspection by MePGCL Officials. f. 11.0 Packing and transportation from the manufacturer’s works to the MePGCL ,Store at Umiam Umtru Stage-IV Power Station, Nongkhyllem BID PRICE 11.1 Price shall be quoted on Firm basis. Bids quoted on variable price will be rejected outright without further communication. 11.2 The Bidder shall furnish the price breakup in the appropriate Schedule of Price to indicate the following: i. Ex-works price of the equipment. ii. Freight and Insurance for delivery of the equipment up to their final destinations. iii. Excise duty, VAT/Sales Tax, tax and any other levies as applicable. 11.3 Bidder shall indicate Bid prices in Indian Rupees only. 12.0 PERIOD OF VALIDITY OF BIDS Bids shall remain valid for 12 (twelve) calendar months after the prescribed date of bid opening, unless otherwise specified. A Bid valid for a shorter period shall be rejected and considered as nonresponsive. 13.0 PRICE BASIS All price Component, for the Excitation Transformer shall remain firm and shall not be subject to any adjustment. 14.0 DELIVERY SCHEDULE The time scheduled for completion of the supply shall be 4 -5 months w.e.f date of Purchase Orders and shall be in totality as per clause 14 of Technical Specification (Part I). 15.0 CONTRACT QUALITY ASSURANCE PLAN The Bidder shall include in his proposal, the quality assurance programme containing the overall quality management and procedures which is followed while manufacturing the equipments. 16.0 COPIES OF BID The Bidder shall prepare two copies of both the Techno Commercial and Price Bid, clearly marking each “Original Bid” and “Copy of Bid”, as appropriate. In the event of any discrepancy between them, the original shall prevail. 5 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS 17.0 SIGNATURE OF BIDS All pages of the Original tender paper issued by the Office should be submitted along with the Bid Rates/Tender duly signed by the tenderer, hereby acknowledging their full awareness and acceptance. 18.0 SEALING AND MARKING OF BIDS The Bidders shall seal the original and each copy of the Bid in an inner and an outer envelope, duly marking the envelopes as “Original” and “Copy”. The inner envelope shall indicate the name and address of the Bidder to enable the Bid to be returned unopened in case it is declared “late” or “rejected”. If the outer envelope is not sealed and marked as required the MePGCL shall assume no responsibility for the Bid’s misplacement or premature opening. 19.0 MePGCL's RIGHT TO ACCEPT OR REJECT ANY OR ALL BIDS The MePGCL reserves the right to accept or reject any bid, and to annul the bidding process and reject all bids at any time prior to award of contract without assigning any reason and without thereby incurring any liability to the affected Bidder or Bidders or any obligation to inform the affected Bidder or Bidders of the grounds for the MePGCL’s action. 20.0 PENALTY FOR LATE DELIVERY In case the Transformers are not delivered within the scheduled delivery date, liquidated damages will be recovered @ ½ % of the undelivered quantity per week or part of a week during which the delivery has fallen arrears, subject to a maximum of 5 % of the ordered value specified. 21.0 22.0 Terms of Payment 21.1 Payments will not be made for equipment/materials damaged during transit. All defective materials shall be replaced/repaired by the supplier free of charge. 21.2 100% payment shall be made on delivery of the equipments. JURISDICTION OF PROCUREMENT CONTRACT The laws applicable to the Procurement Contract shall be the laws in force in India. The High Courts of SHILLONG shall have exclusive jurisdiction in all matters arising under this Procurement Contract. 23.0 OPENING OF BID 23.1 The Bid will be opened in two parts. Part-I (EMD & Techno-Commercial) will be opened first. 23.2 The Techno-commercial bid shall then be evaluated. 23.3 The Price bid (i.e Part II) of only those bidders who have obtained the minimum qualifying marks as stated in Clause 3.0(ii) (c) shall be opened. 6 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS 23.4 The Price bid shall be opened on the date and scheduled time (or the next working day, in case scheduled date is declared a holiday) in presence of the Bidders or their authorized representative after opening and evaluation of the Techno Commercial Bid. 23.5 Pre Bid Meeting will be held on the : Opening of Bid Security and Techno Commercial Bid : Price Bid Opening shall be notified at a later date. 24.0 Bill of Quantity Bill of Quantity against this Tender is as enclosed in Annexure V. The quantity is tentative and based on the past annual requirement. The MePGCL reserves the right to split the purchase order among the qualified Bidders, as deem fit. 25.0 Panel of Qualified Bidders Based on total marks scored in the technical and price evaluation, a panel of qualified Bidders will be and ranked in order of the points obtained. If whatever reasons, the top ranked Bidder(s) fails to execute the supply order that might be placed, the next ranked bidders will be offered. 26.0 Address for Communication:The Superintending Engineer (GC-I) C/o Chief Engineer, Generation Meghalaya Power Generation Corporation Ltd Short Round Road, Shillong-793001 East Khasi District, Meghalaya : 0364- 2591515 segen.umiam@gmail.com 7 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, INSTRUCTION TO BIDDERS AND GENERAL TERMS & CONDITIONS 8 ANNEXURE-A PROFORMA OF BANK GUARANTEE FOR BID GUARANTEE (To be stamped in accordance with stamp Act) The non-judicial stamp paper should be in the name of issuing bank Ref……………………. Bank Guarantee No………………. Date: …………………………….. To, The Superintending Engineer Generation Circle-I MePGCL, Umiam Dear Sir, In accordance to the Invitation to Bid under your specification No. ………………………. M/S ……………………………… having its Registered/Head Office at ………………………….. (Hereinafter called the ‘Biddder’) wished to participate in the said Bid or ……………………… and you, as a special favour have agree to accept an irrevocable and unconditional Bank Guarantee for an amount of ……………………. Valid up to ………………………… on behalf of Bidder in lieu of the Bid deposit required to be made by the Bidder, as a Condition precedent for participation in the Said Bid. We the ………………….. Bank at ……………………………. having our head Office at ……………………………….. (local address) guarantee and undertake to pay immediately on demand by Meghalaya Energy Corporation Limited the Amount of …………………………………………………………………………………………………… (in words and figures). Without any reservation, protest, demur and recourse. Any such demand made by said ‘Owner’ shall be conclusive and binding on us irrespective of any dispute or difference raised by the Bidder. This guarantee shall be irrevocable and shall remain valid up to and including ……………… @ …………………….. If any further extension of this guarantee is required, the same shall be extended to such required period (not exceeding one year) on receiving instruction from M/s …………………………………. On whose behalf this guarantee is issued. In witness whereof the Bank, through its authorized officer, has set its hand and stamp on this the ………………………………… day of 200…………………….at …………………….. WITNESS ……………………………………... ………………………………………… (Signature) (Signature) ……………………………………... ………………………………………… (Name) (Name) …………………………………….. …………………………………………. (Official Address) (Official Address) @ This date shall be thirty (30) days after the last date for which the bid is valid. ANNEXURE – B PROFORMA OF BANK GUARANTEE FOR PERFORMANCE (To be stamped in accordance with stamp Act) Ref……………………. Bank Guarantee No………………. Date: …………………………….. To, The Superintending Engineer Generation Circle-I MePGCL, Umiam Dear Sir, In consideration of Meghalaya Energy Corporation Limited (hereinafter referred to as the ‘Owner’, which expression shall unless repugnant to the context or meaning thereof include its successors, administrators and assigns) having awarded to M/s …………………….. with its registered/Head office at …………………………………….. (hereinafter referred to as the ‘Supplier’, which expression shall unless repugnant to the context or meaning thereof include its successors, administrators, executors and assigns), a purchase order by issued of Owners Letter of Award No ………………………… dated …………………. And the same having been acknowledged by the Supplier, resulting in a purchase order bearing No….. ……………….. dated ……………….. valued at ………………. For …………………. (scope of order) and the Supplier having agreed to provide a Performance Guarantee for the faithful performance of the entire P.O equivalent to ………………………….. being. (%) percent) of the said value of the P.O to the Owner. We ……………………………………………………………………………………………….. (Name & Address) having its Head Office at ……………………………………….. (hereinafter referred to as the ‘Bank’, which expression shall, unless repugnant to the context or meaning thereof include its successors, administrators, executors and assigns) do hereby guarantee and undertake to pay the Owner, on demand any or all monies payable by the supplier to the extend of ……………………………………………….. as aforesaid ………………………………………………. (days/month/year) at any without time any reservation, contest, recourse or protest and/or without any reference to the supplier. up to demur, Any such demand made by the Owner on the bank shall be conclusive and binding notwithstanding any difference between the Owner the Supplier or any dispute pending before any Court Tribunal, Arbitrator or any other authority. The bank undertakes not to revoke this guarantee during its currency without previous consent of the Owner and further agrees that the guarantee herein contained shall continue to be enforceable till the owner discharges this guarantee. The Owner shall have the fullest liberty without affecting in any way the liability of the Bank under the guarantee, from time to time to extend the time for performance of the P.O by the Supplier. The Owner shall have the fullest liberty, without affecting this guarantee, to postpone from time to time the exercise of any powers vested in them or of any right which they might have against the Supplier, and to exercise the same at any time in any manner, and either to enforce or to forbear to enforce any covenants, contained or implied, in the P.O between the Owner and the Supplier or any other course or remedy or security available to the Owner. The Bank shall not be released to its obligations under these presents by any exercise by the Owner of its liberty with reference to the matters aforesaid or any of them or by reason of any other act of omission or commission on the part of the Owner or any other indulgences shown by the Owner or by any other matter or thing what so ever which under law would, but for this provision have the effect of relieving the Bank. The bank also agrees that the Owner at its option shall be entitled to enforce this guarantee against the Bank as a principal debtor, in the first instance without proceeding against the Supplier and notwithstanding any security or other guarantee the Owner may have in relation to the Supplier’s liabilities. Notwithstanding anything contained hereinafter our liability under this guarantee is restricted to ………..and its shall remain in force up to and including ……………………… and shall be extended form time to time for such period (not exceeding one year), as may be desired by M/s ………………….. on whose behalf this guarantee has been given. Dated this the …………………… day of ………………………. 20…… at ………………… WITNESS ……………………………………... ………………………………………… (Signature) (Signature) ……………………………………... ………………………………………… (Name) (Name) …………………………………….. …………………………………………. (Official Address) (Official Address) Attorney as per Power Of Attorney No……………………. Date ……………………………….. NOTES: this sum shall be ten cent (10%) of the Contract price. The date shall be ninety (90) days after the end of Warrantee period as specified in the Purchase Order. 1. The Stamp papers of appropriate value shall be purchase in the name of issuing bank. ANNEXURE – C SUPPLY Of 2 NOS OF DRY TYPE CAST COIL RESIN EXCITATION TRANSFORMER FOR UMIAM-UMTRU STAGE-4 POWER STATION, NONGKHYLLEM OF MEGHALAYA POWER GENERATION CORPORATION LIMITED (FIRM PRICE DECLARATION SCHEDULE) Bidders Name & Address: To, The Superintending Engineer Generation Circle-I MePGCL, Umiam We declare that our price components are on FIRM basis. (Signature)………………………………………... Name of the Manufacturer ………………………. Address: …………………………………………. ……………………………………………………. Date: Place: Common Seal Annexure –D SCHEDULE OF PRICES (TO BE FILLED BY THE TENDERER) Sl.NO Item Particulars 1 2 Nos of Dry type Cast Resin Excitation Transformer and accessories as per Technical Specification.(Part I) Unit ExExcise CST (`.) Works Price Duty (`.) (`.) Freight & Insurance Charges (`.) Total Unit Price (`.) Remarks Signature of Tenderer Name (IN BLOCK LETTERS): Stamp: Date: MEGHALAYA POWER GENERATION CORPORATION LIMITED Technical Specification (Part – I) TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, 3rd March 2015 MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) Contents Section – A 1.0 Scope 2.0 Codes and Standards 3.0 Bidder‟s eligibility criteria 4.0 Constructional features 5.0 Enclosures for transformer 6.0 Fittings and accessories 7.0 Performance requirement 8.0 Inspection and tests 9.0 Tolerance 10.0 Bid evaluation and penalty criteria 11.0 Acceptance criteria 12.0 Guarantee period 13.0 Documentation 14.0 Delivery period 15.0 Brief technical specification 16.0 Guaranteed Technical Particulars 17.0 Load features. Section – B: 1.0 Schedule of prices 2.0 Schedule of essential spares 3.0 Activity schedule 4.0 Schedule of deviations MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) SECTION – A MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) TECHNICAL SPECIFICATIONS OF 375 KVA 11KV/240V TRANSFORMER 1. Scope The scope includes design/engineering, manufacture, testing and supply of resin cast dry type transformer of rating 375 KVA 11KV/240V, 50 Hz with required spares and accessories, as per the technical specification. 2. Codes and Standards The design, manufacture and performance of equipment shall comply with all currently applicable statutes, regulations and safety codes. Except where modified by this specification wherever applicable all material and equipments shall conform to the requirements of latest Indian Electricity Rule (IER) and below given standards, including all amendments. Sl No Description Standard 1. Dry type transformer : IS 11171 & IS 2026 2. Current transformer (protection class) : IS 2705 3. Degree of Ingress Protection for control gear : IS 12063 4. Bushings for Alternating voltage above 1000V : IS 2099 5. Thermal Evaluation & Classification of Electrical Insulation. : IS 1271 6. Fittings and accessories : IS 3639 7. Measurement of transformer and reactor sound levels : IEC 60076-10 or NEMA TR-1 The overriding effect of various applicable documents shall be as follows: 1. Tender technical specification. 2. Applicable Codes & Standards. 3. Approved vendor drawings. 3. Bidder Eligibility Criteria: The Bidder shall comply with the following conditions: The Bidder should be the Original Equipment Manufacturer (OEM/ authorized dealer of the OEM. The OEM shall have experience of design/engineering, fabrication, testing and supply of cast resin dry type transformer of minimum 375kVA rating in last 5 (five) years from the date of tender. MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) In support of above and the documentary evidence in respect of OEM five years experience shall be submitted i.e. copies of orders, completion /performance certificate with the contract details of the end users. The bidder shall submit balance sheets, profit & loss statement for last 3 (three) financial years. During this period the bidder shall not have incurred overall loss and average annual turn-over shall not be less than Rs. 1.0 crore. Note : (a) In case bidder is not OEM, he should also submit the agreement with OEM, showing that he is authorized to quote on their behalf and the OEM shall support the bidder for all warranty etc. (b) Price not to be filled in Part-I (Technical offer) 4. Constructional Features: 4.1 General Requirements: The dry type cast resin transformer shall be AN (Air Natural) cooled. All material used shall be new, best quality and of the most suitable class for working conditions as per the tender technical specification. The material shall withstand the indoor atmospheric conditions, overloads, over excitation and short circuits as per above standards without distortion, deterioration and the settings-up of undue stresses in any part. 4.1.1 For similar specifications, the supplied transformer shall be identical and their parts shall be interchangeable. 4.1.2 4.2 4.2.1 4.2.2 4.2.3 4.2.4 4.2.5 4.2.6 4.2.7 4.3 4.3.1 4.3.2 Nuts, bolts and pins shall be provided with lock washers or locknuts. Core: Transformer design shall be core type. The core shall be made out of high grade, nonageing, low loss cold-rolled grain oriented (CRGO) silicon steel laminations. The core shall be painted and insulated with suitable resin to protect it against corrosion. The lamination shall be free from burrs and sharp projections. The yoke laminations shall be interleaved and carefully assembled to avoid air-gaps in the magnetic circuit. The core shall be earthed as per the relevant standards. The Insulation structure in between core to bolts and core to clamp plates shall withstand a minimum voltage of 2500 V for one minute. All steel sections used for supporting the core shall be free from burrs. The design of the magnetic circuit shall be such as to avoid static discharges, development of short circuit paths within itself or to the earthed clamping structure. The assembled core with all the clamping structures shall be free from deformation and shall withstand the vibrations during operation. The core clamping structure shall be designed to minimized eddy current losses. Windings: The Cu-ETP grade copper conductor shall be used for transformer HV and LV windings. The design and arrangement of the windings and their insulation shall be such as to ensure uniform distribution of the voltage surges among all the coils of the windings. The windings shall be provided with Class-F epoxy resin cast insulation. The insulation shall have high tensile and dielectric strength. Enough measures shall be taken during casting to avoid the void formation, cracking and crazing etc. of the cast coils. MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 4.3.3 4.3.4 4.3.5 Both HV and LV windings of each phase shall be separately cast on rigid tubular coil coaxially arranged under vacuum in to moulds. The epoxy resin insulation system shall be fibre glass strengthened. The resin used for windings insulation shall be non-hygroscopic to prevent the penetration of moisture into windings. It should be possible to energize the transformer without pre-drying even after a long period of service interruption. The resin used shall be non-inflammable, self-extinguishing, void free and suitable for tropical climate with 100% relative humidity. In the case of windings provided with taps, the inter-turn insulation of tapped windings shall be reinforced to obtain uniform stress distribution. The transformer shall be able to withstand short circuits as well as switching and lightning/atmospheric impulse voltages as specified in the IS 11171 Standard. The leads and connections shall be mechanically strong and adequately brazed to withstand short circuit forces and transportation shocks. 4.4 Core and Coil Assembly: The cast coils are inserted on to the core limbs. The resin cast spacer blocks, end blocks and separators shall be used as required. 4.5 Earthing: Single point earthing shall be used for magnetic circuit. The frame work and clamping arrangements of core and coil shall be securely earthed by copper strip connection to the main frame and enclosure. Two earthing terminals suitable for 75X10 mm GI strip shall be provided on the frame for enclosure earthing. 4.6 Tapping: Off circuit tap changing link shall be provided with total tapping range of +10% to –10% in steps of 2.5%. The tapping link shall be on high voltage side. The transformer shall be capable of delivering its rated output at any tap position without damage. 4.7 Terminal box arrangement: 4.7.1 The HV side termination facility of the transformers shall be designed for connecting 11 KV suitable for sandwich bus-bar with flexible copper conductor. HV terminals shall be extended up to a convenient height. The conductor entry shall be from top. Preferably the bus- bars shall be supported by the supporting insulators from the top frame of the enclosure. The winding delta formation on HV side shall be in supplier‟s scope. 4.7.2 The LV side terminals and the LV termination box of transformers shall be suitable for Alluminium cable connection. The earthing stud shall be provided on LV termination box for cable earthing conductor. The winding star formation on LV side shall be in supplier‟s scope. 4.7.3 The LV neutral terminal of the star connected winding shall be brought out at separate insulated terminals. One neutral terminal shall be provided by side of the phase terminals for connecting neutral to neutral bus-bar in the LV termination box. Second neutral terminal shall be provided to facilitate the earth conductor down to the ground level. The terminal shall be suitable for connecting with two separate earthing pads. 4.8 Support Insulators: MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) a) Support Insulators shall be designed and tested to comply with the applicable standards. b) HV terminals rated for minimum current 400A shall have non-ferrous and nonmagnetic flanges and hardware. c) Air clearance and creepage distances shall be maintained as per the relevant standard. d) Preferably the material for support insulators shall be Porcelain or epoxy resin cast. 4.9 Current Transformer (CT): a) The over current CT shall be epoxy resin casted under vacuum and having ratio of 800/1A, class 5P10, Burden 15VA. This CT shall be provided in each phase of LV side. Class of insulation system of the CT shall be class F. b) CT Secondary leads shall be brought to the marshalling box. c) CT details shall be indicated on nameplate of the transformer. 4.10 Temperature sensor & winding temperature indicator (WTI); a) Temperature sensors: Two (2) numbers, reputed make simplex type (Platinum) PT100 shall be provided in each phase at suitable place for measuring hot spot temperature. b) A multi channel digital winding temperature indicator shall be provided to display the temperature of the windings. c) The indicating instrument shall be provided with four adjustable electrically independent ungrounded contacts brought out to separate terminals for winding temperature alarm trip. The WTI shall be compatible to 220V DC and 230 V, 50Hz. AC auxiliary supplies. d) WTI scanner shall have remote PC (personal computer) communication facility. 4.11 Marshalling box: a) The weather proof-marshalling box shall be mounted on the transformer housing. All door, covers and plates shall be provided with neoprene gaskets. Bottom of the marshalling box shall be at least 600 mm above floor level and provided with removable bolted & undrilled gland plate etc and to be fixed to the existing enclosure. The required number of knock-out punches shall be provided for outgoing control cables. b) All contacts for alarm, trip and indication circuits shall be electrically potential free, wired for auxiliary supply as specified and brought out to separate terminals at the terminal blocks in the marshalling box. If required, separate MCBs shall be provided for protection, isolation and distribution of AC & DC control supplies in the marshalling box. Wiring shall be PTFE insulated (Insulation for wire & cable shall be consistence with the ambient temperature in the housing). The wiring conductor shall be stranded copper and of sizes not less than 4 sq.mm for CT circuit and 2.5 sq.mm for other control circuits. CT terminals shall be provided with standard shorting facility. The wires shall be drawn through neatly clamped conduits. Engraved identification ferrules, marked as per the approved wiring diagrams shall be provided on each wire. Ferrules shall be of yellow colour with black lettering. Preferably the terminals shall be stud type and provided with crimping type cable sockets. 5.0 Enclosure for transformer: The transformer shall be constructed so that it can be accommodate in the existing MS enclosure . Dimension as given in the sketch below. MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 6.0 Fittings and Accessories: Following fitting and accessories shall be provided: 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 7.0 HV/LV terminals suitable for the purchaser‟s external conductors. Rating, terminal marking and danger plates. Three earth terminals per transformer, each suitable for earth conductor‟s of size 2 nos. 75X10 mm GI strip for earthing of the body of the transformer and its enclosure. Lifting lugs for: 6.4.1 Complete transformer. 6.4.2 Core-Coil assembly. The under base shall be provided with channels etc. Four bi-directional rollers in base frame for movement of complete transformer assembly. The stopper arrangement to lock the transformer in the required position shall also be provided. Marshalling box. Neutral earth terminal with lugs. Six number PT100 RTDs with WTI display. Off circuit tap links. Performance requirements: 7.1 Transformers shall operate without abnormal heating at the rated KVA at any voltage within + 10 percent of the rated voltage of that particular tap. 7.2 Transformer shall be designed for 110% continuous over fluxing withstand capability. 7.3 The continuous and short time over loading capacities shall be furnished in detail. Over loads shall be allowed within the condition defined in the applicable standards. Terminal, taps or any other auxiliary equipment shall not limit such over loading. The transformer shall be also be suitable for feeding power to the load as per the load features (refer clause number 17) of the specifications. 7.4 The neutral terminal of windings with star connection shall be designed for the highest over-current that can flow through this winding. 7.5 The bidder shall ensure that the design and manufacturing of the transformer shall be such as to reduce noise and vibration level. The sound level of the transformer with its enclosure in position shall not exceed 66dBA measured in accordance with NEMA TR-1 or IEC 60076-10 Standard. 7.6 The apparent charge limit shall be 20pc during partial discharge test as per IS 11171. MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 7.7 7.8 The transformer HV winding shall be suitable for vacuum circuit breakers switching. All other performance requirement as per the relevant standards and codes shall be met with the conditions specified above. 8 Inspection and Tests: At all limits, the purchasers representative shall have access to the manufacturer or submanufacturer works for the purpose of witnessing, tests and ascertaining that the transformer being supplied conform to the requirements of this specification. The stage inspection shall be performed during fabrication stage. The bidder shall provide the detailed activity schedule from stage inspection. The bidder shall inform the purchaser at least in 15 days of the testing due date and ask for their representative‟s availability. The detailed test schedule shall also be submitted. The visual checks including dimensions and clearance shall be performed during Predispatch Inspection (PDI). In addition to the above checks, the following routine and special tests shall be carried out on each assembled transformer. 8.1 Routine Test: The tests shall be as below: a. Measurements of Resistance of windings. b. Measurements of voltage ration at all taps and check of voltage vector relationship. c. Check test for polarity. d. Measurement of impedance voltage (principal tap), short circuit impedance and load loss at rated current. e. Measurement of No-Load loss and current. f. Separate source voltage withstand test. g. Induced over voltage withstand test h. Measurement of insulation resistance. i. HV tests on auxiliary & control wiring. j. Calculation of the regulation and efficiency at rated load on unity P.F and 0.8 P.F lag. All routine tests shall be carried out as per the IS 11171/2026. 8.2 Special Test: a. Partial Discharge test. b. Measurement of acoustic sound level. c. Measurement of zero sequence impedance. 8.3 Type Test: These tests shall be performed on one of the transformers (as selcted by the purchaser during PDI) from the lot. a. The temperature rise test as per IS 11171. b. Lightning impulse test at 75kV full standard (1.2/50usec) lightning impulse. This test shall be carried out as per IS 11171, at IEC/CPRI/ERDA/NABL/Govt. approved labs only. If transformer fails in any of the tests specified, the purchaser shall have the option to reject complete lot. Additional test shall be performed to determine the reason of MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) failure and after necessary modifications: all the tests shall be repeated to prove that the modified transformer meets with the requirements of the specification in all respects. The cost, if any, for the modification, testing including any additional test required for verification of the transformer performance shall be to the account of the bidder. 9 Tolerance: Allowable tolerance for other parameters except losses shall be as per the IS-2026 Part-I. In respect of total losses maximum +10% shall only be permissible, subject to penalty as per clause 10 of the specification. The losses in the guarantees Technical particulars (GTP) submitted by the supplier shall be the reference for percentage loss and bid evaluation. 10. 1 2 Bid evaluation & Loading/Penalty Criteria: Formula for evaluation of bids („base case‟ will be the lowest of guaranteed losses separately for Load losses in kW (WC) & No-Load losses in kW (Wi) of the bids received. Evaluated cost = (F.O.R.cost in + Loading (in ). The formula for loading is given by “Loading (in ) = 148000 x (guaranteed NoLoad losses in kW – Wi „base case‟) + 47000 x (guaranteed Load losses in kW – Wc „base case‟)]” Rates of penalty for exceeding the In case the measured total loss figure exceeds guaranteed losses the GTP figures by +10% the transformer shall be liable for rejection. If measured total loss figure exceed GTP by less than 10%, the transformer may be accepted subject to penalty at the rate of 148000/kW for additional NoLoad losses and 47000/kW for additional Load losses. No rebate shall be given for the actual losses being less than the guaranteed losses submitted by the bidder. 11. Acceptance Criteria: Successful testing as per clause 8 of the specification. 12. Guarantee Period: The transformer shall be guaranteed for a period of minimum 2 (Two) years from the date of acceptance or 12 months from the date of commissioning whichever is earlier at MePGCL after delivery. 13. Documentation: The bidder shall submit the documents at different stages as given below. 13.1 With Bid (Technical/Part-1): a. Copies of order, completion/performance certificate and contact details of the end users in support of OEM experience. Refer clause 3.1 of bidder eligibility criteria of the technical specification. MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) b. c. d. e. f. g. Copies of the balance sheets, profit & loss statement of the bidder for last 03 (three) financial years. Refer clause 3.2 of bidder eligibility criteria of the technical specification. Detailed catalogues/datasheet and literature indicating technical specifications. The following Type tests reports of cast resin dry type transformer minimum 375 kVA rating. (i) Impulse voltage withstand test. (ii) Short Circuit withstand test. (iii) Temperature rise test report for offered item rating. Exhaustive Quality Assurance Plan (QAP) of the manufacturer. Duly Filled GTP as per the format given in clause 16 (GTP) Detailed activity schedule as per the format given in section – B clause 3.0 Note: The offer(s) without copies of the above mentioned shall be liable for summary rejection. 13.2 After placement of purchase Order: The following documents shall be submitted for approval, before taking up fabrication. (a) Detailed transformer drawings along with LV and HV termination box dimensions. (b) Earth terminals, marshalling panel details and bill of material etc. (c) Supporting calculations for additional losses caused by harmonic loading (refer clause 17) and corresponding hot spot/average winding temperature rise. (d) Graph of core loss in watt/kg versus flux density (wb/m2) for the transformer core material. (e) Continuous and short time over loading details. 13.3 On Completion: Six(06) sets of bound manuals of final detailed drawings, control drawings (marshalling panel), test reports, technical catalogues, installation instructions, O&M instructions, guarantee certificate & compliance report etc, along with their soft copy. 14. Delivery Period: The bidder shall quote for minimum delivery period. In this regard, a detailed activity bar chart shall be submitted by the bidder fro manufacturing, testing at works, transportation and delivery at MePGCL. Expected supply schedule for the total work is around 4-5 months from the date of order placement. 15. Brief technical specification: The technical details are as follows: TECHNICAL PARTICULARS 1. Rating : 375 kVA 2. Frequency : 50Hz ±3% 3. No of Phases : 3(Three) 4. Rated voltage (i) HV (ii) LV : 11000 volts with +10% & -10% tolerances : 240 volts 5. Winding connections MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) (i) HV (ii) LV : Delta : Star 5. Vector Group : Dyn5 6. Seismic Zone : Zone V 8. Maximum ambient air temperature : 40ºC 9. Max. daily average ambient temperature : 30ºC 10. Service : Indoor 11. Other service conditions : As per IS:11171/2026 12. Class of Insulation : minimum class –F 13. Allowance Max. temp. rise of windings : 90ºC 14. Tapping 15. Percentage Impedance voltage at principal tap. : 6.0 % 16. Type of cooling : AN 17. Terminal arrangement HV LV : 3 core, 11kV Bus Duct : 1100V Al cable up to 400 sq.mm. 18. 19. Sound level in transformer System voltage (i) HV side a. Normal System voltage b. Highest system voltage : +10% to –10% in steps of 2.5% on HV side through off circuit tap links. : 66dBA (measured as per standards IEC 60076-10 or NEMA TR-1 : 11kV : 12kV 20. System earthing : Solidity grounded system neutral. 21. System fault level : 40 KA for 1 sec at 11kV 22. Insulation voltages a. Impulse b. Power frequency HV c. Power frequency LV : 75 KV (peak) : 28 KV (rms) : 3 KV (rms) MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 16. Guaranteed Technical Particulars (GTP) for Transformer: The bidder shall submit the filled GTP along with Part-I (technical bid) Guaranteed Technical Particulars for Transformer Sl No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Description Name of manufacture Model & type Suitable for indoor installation Standards followed by the manufacturer or compliance to the standard Relevant standard (IS/IEC) for short time overloading capacity Rated KVA Short circuit withstand capacity in kA (with time interval) Rated Voltage i)HV side ii) LV side Rated current i)HV side ii) LV side Tapping +10% to –10% in steps of 2.5% on HV side, through off circuit tap links. HV/LV windings type. Class of insulation system Winding Connections: HV-Delta & LV-Star Vector group reference : Dyn5 Rated frequency : 50Hz Type of cooling : AN Enclosure class of IP (Ingress Protection)- Existing to be Used Maximum temperature rise of windings at rated load (as per IS 1171) Guaranteed No-Load losses on principal tapping at rated voltage and rated frequency. Specify, whether the loss figure is maximum or with IS tolerance. Guaranteed Load losses on principal tapping at rated current, corrected to 75ºC windings temperature. Specify, whether the loss figure is maximum or with IS tolerance Percentage impedance at rated current for the principal tapping Percentage reactance at rated current and rated frequency Efficiencies at 75ºC and 0.8 P.F Lag on: 1. Full load 2. 75% of full load 3. 50% of full load 4. 25% of full load Magnetizing inrush current value Percentage regulation at 75ºC : a) At full load : Detail/parameter Yes/No Yes/No Yes/No Yes/No Yes/No Yes/No Yes/No MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 (1) unity power factor (2) 0.8 power factor lag b) At 50% full load: (1) unity power factor (2) 0.8 power factor lag No-Load current and power factor at rated voltage and rated frequency No-Load power factor at rated voltage and rated frequency Highest system voltage for which transformer windings are suitable (a) HV winding (b) LV winding Maximum flux density at rated voltage Each Phase winding turns (a) HV winding (b) LV winding Current density (at rated current) HV winding in A/mm2 Current density (at rated current) LV winding in A/mm2 Insulation level: a) Separate source power frequency withstand b) Full wave lightning impulse withstand c) Induced over voltage withstand Weight: a) Core and Windings b) Enclosure N/A C) Total Dimensions: a) Length b) Breadth C) Height Compliance to Environment class as per IEC 60076:E0 or E1 or E2 Compliance to Climate class as per IEC 60076: C1 or C2 Compliance to Fire Proof class as per IEC 60076: F0 or F1 Transformer acoustic level (measured as per standards IEC 60076 – 10 or NEMA TR-1) Apparent charge limit during partial discharger test as per IS 11171. Guarantee period: minimum 2 (Two) years from the date of Yes/No acceptance at MePGCL. Signature & Seal of the Bidder MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) SECTION – B MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 1.0 Schedule of Prices: Item. Description Qty No. 1.0 Design/Engineering, 02 fabrication, Assembly, Testing Nos at works and supply of continuous duty, 375 kVA, 11kV/240V, 50Hz three phase dry type cast resin transformer along with required spares (refer 2.0 Section-B, schedule of essential spares) & accessories as per specification Supply Rate Taxes & Duties Amount PRICES NOT TO BE FILLED IN PART-I Signature & Seal of the Bidder MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 2.0 Schedule of essential spares: The bidder shall also supply the spares as per the list mentioned below. Item wise unpriced list of these spares shall be confirmed along with Part-I of the offer. The prices shall be indicated for individual spare component along with Part-2 (Price bid) of the offer. Sl. No 1 2 3 4 5 6 7 8 9 Description Qty. Off Circuit tap links of transformer WTI LV insulators HV insulators Rating, terminal and danger plates Earthing terminal with lugs Complete set of gaskets REF CT Support insulators 01 set Supply Rate Amount 02 Nos 01 set 01 set 01 set 01 No. 01 set 01 No. 01 set Signature & Seal of the Bidder MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 3.0 Activity Schedule: The bidder shall submit the activity schedule along with the offer. After placement of order duration required for each activity should be mentioned separately as per the format given below. Sl. Activity Duration No 1 Design and Engineering 2 Submission of fabrication drawing for approval 3 Submission of design calculation for additional loss and temperature rise. 4 Fabrication/stage inspection 5 Assembly and Testing at Works 6 Supply at site Signature & Seal of the Bidder Desirable delivery schedule is 4-5 months. MEGHALAYA. POWER GENERATION CORPORATION LIMITED TENDER DOCUMENT FOR MANUFACTURE AND SUPPLY OF 2 NOS OF DRY TYPE (CAST RESIN) EXCITATION TRANSFORMERS FOR UMIAM-UMTRU STAGE-IV POWER STATION, NONGKHYLLEM, TECHNICAL SPECIFICATION (PART – I) 4.0 Schedule of deviations: There are no deviations in the specification of the offer item(s) except for the following. SL. Tender Specifications Deviation Detail Remarks/Justification No Para/Point No Signature & Seal of the Bidder