Lightweight Steel Twist Beam Achieves 30 Percent Mass

advertisement

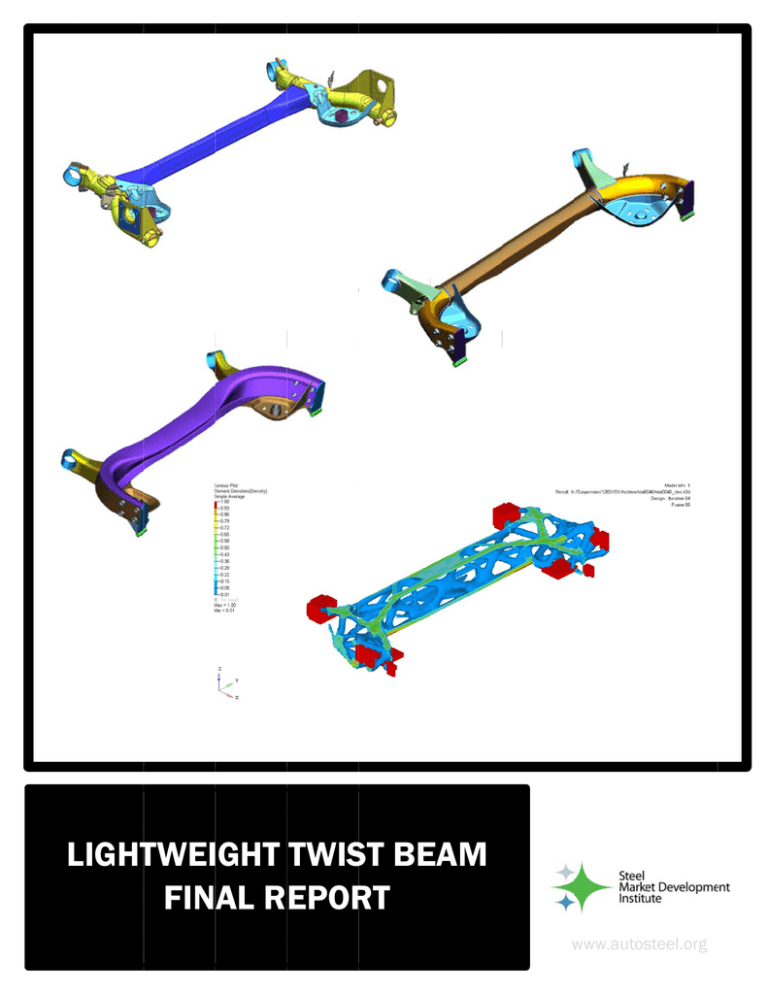

FINAL L REPO ORT: Ligh htweigh ht Twist Beam m Devellopmen nt Prepared by LLIGHTTWEIGHT TWIS ST BE EAM FINAL REPOR RT w www.autossteel.org Lightweight Twist Beam Development – Final Report Acknowledgements OEM Project Team: Doug Howe Ford Motor Company Ranvir Singh Jalf Chrysler Group LLC William Pinch General Motors Company Cory Taulbert General Motors Company Steel Project Team: David Anderson Steel Market Development Institute Jon Fleck AK Steel Corporation Tom Wormold ArcelorMittal USA LLC Dean Kanelos Nucor Corporation Srinivasan Laxman Severstal North America Jon Powers Severstal North America Paul McKune ThyssenKrupp Steel USA, LLC Bart DePompolo United States Steel Corporation Multimatic Engineering Team: Nik Balaram Tudor Boiangiu Pardeep Dhillon Eric Gillund Bob Howell Scott Keefer Paul Saadetian Murray White 2 Executive Summary The objective of this project was to develop a lightweight steel proof-of-concept twist beam design that achieves a 15 to 25% mass reduction with equivalent structural and elasto-kinematic performance relative to the baseline design at a ≤ 10% cost premium. A current production original equipment manufacturer (OEM) twist beam assembly was used to establish the baseline for package, performance, mass and cost. Computer-aided engineering (CAE) structural optimization methods were used to determine the initial designs. Two designs were selected for further development and one design was subsequently selected as the best-performing and lightest alternative that met all typical performance criteria. An iterative optimization strategy was used to minimize the mass of each design, while meeting the specified strength, durability and elasto-kinematic requirements. The manufacturing cost was estimated for the preferred design relative to the baseline design for three production volumes. The results of the study indicate that the preferred U-Beam Design based on 22MnB5 tubular construction with DP780 and SPFH540 sheet achieves a 30.0% mass reduction relative to the baseline assembly, at a 12 to 15% premium in manufacturing cost. The S-Beam Design based on 22MnB5 sheet, DP780 tube and HSLA550 materials was predicted to have a 14.9% mass reduction relative to the baseline assembly. All designs were deemed manufacturable based on expert manufacturing assessment and relevant production application examples. Lightweight Twist Beam Development – Final Report Table of Contents Executive Summary ..................................................................................................................... 3 Purpose .......................................................................................................................................... 9 Conclusions ................................................................................................................................... 9 Recommendations........................................................................................................................ 9 Baseline Design .......................................................................................................................... 11 Design Targets ............................................................................................................................ 12 Structural Performance .......................................................................................................... 13 Mass .......................................................................................................................................... 14 Package..................................................................................................................................... 16 Corrosion ................................................................................................................................. 16 Cost ........................................................................................................................................... 16 Development Process ................................................................................................................ 18 1. Concept Development ....................................................................................................... 18 2. Design Development .......................................................................................................... 19 3. Manufacturing and Corrosion .......................................................................................... 20 4. Cost Assessment ................................................................................................................. 20 Design – Package Effects ........................................................................................................... 21 Design Proposals ........................................................................................................................ 23 U-Beam Design ....................................................................................................................... 23 S-Beam Design ........................................................................................................................ 24 Performance ................................................................................................................................ 26 Materials................................................................................................................................... 26 Material Modeling Considerations ...................................................................................... 28 Material Selection ................................................................................................................... 29 Durability ................................................................................................................................. 32 Extreme Loads ......................................................................................................................... 34 Performance Summary .......................................................................................................... 37 Mass ............................................................................................................................................. 38 Elasto-Kinematic Performance ................................................................................................. 40 Manufacturing ............................................................................................................................ 44 U-Beam Design ....................................................................................................................... 44 S-Beam Design ........................................................................................................................ 44 Corrosion ..................................................................................................................................... 46 4 Lightweight Twist Beam Development – Final Report Cost Estimates ............................................................................................................................ 47 Assumptions ............................................................................................................................ 47 Material Costs ...................................................................................................................... 47 Design ................................................................................................................................... 47 Program ................................................................................................................................ 48 Variable Costs ...................................................................................................................... 48 Fixed Costs ........................................................................................................................... 48 Component Costs ................................................................................................................ 48 Cost Comparison .................................................................................................................... 48 References ................................................................................................................................... 51 Appendix 1: Kinematics and Compliance Plots .................................................................... 52 5 Lightweight Twist Beam Development – Final Report List of Figures Figure 1: Baseline OEM Twist Beam Assembly....................................................................... 9 Figure 2: OEM Baseline Design................................................................................................ 11 Figure 3: Twist Beam Design Targets...................................................................................... 13 Figure 4: Structural Performance Targets ............................................................................... 14 Figure 5: Baseline twist beam Assembly Mass Summary .................................................... 15 Figure 6: Package Volume and Design Environment ........................................................... 16 Figure 7: Development Process Diagram ............................................................................... 18 Figure 8: Volume Topology Optimization ............................................................................. 19 Figure 9: Volume Topology Optimization Using an Extruded Constraint ....................... 19 Figure 10: Candidate Design Concepts ................................................................................... 20 Figure 11: Twist Beam Example with Outboard-Driven Hub Fasteners ........................... 21 Figure 12: Damper Attachment for OEM Baseline and U-Beam Designs ......................... 22 Figure 13: U-Beam Design Concept ........................................................................................ 24 Figure 14: S-Beam Design Concept ......................................................................................... 25 Figure 15: Twist Beam Finite Element Models ...................................................................... 26 Figure 16: Engineering Stress-Strain Curve Comparison .................................................... 27 Figure 17: Material Fatigue Property Reductions – HAZ .................................................... 28 Figure 18: HAZ – Durability Implementation ....................................................................... 29 Figure 19: HAZ – Strength Implementation .......................................................................... 29 Figure 20: U-Beam Design Material Selection and Gage...................................................... 30 Figure 21: S-Beam Design Material Selection and Gage....................................................... 31 Figure 22: OEM Baseline Design Material Selection and Gage ........................................... 31 Figure 23: Predicted Durability Life Comparison ................................................................. 32 Figure 24: Predicted OEM Baseline Design Durability Life ................................................ 33 Figure 25: Predicted U-Beam Design Durability Life ........................................................... 33 Figure 26: Predicted S-Beam Design Durability Life ............................................................ 34 Figure 27: Predicted Extreme Load Permanent Set Comparison ........................................ 35 Figure 28: Predicted OEM Baseline Extreme Load Plastic Strain ....................................... 35 Figure 29: Predicted U-Beam Design Extreme Load Plastic Strain .................................... 36 Figure 30: Predicted S-Beam Design Extreme Load Plastic Strain ..................................... 36 Figure 31: Twist Beam Assembly Mass Comparison............................................................ 38 Figure 32: Twist Beam Structure Mass Comparison ............................................................. 39 Figure 33: K&C Results: Bounce – Bump Steer...................................................................... 41 6 Lightweight Twist Beam Development – Final Report Figure 34: K&C Results: Bounce – Bump Camber ................................................................ 41 Figure 35: K&C Results: Roll - Roll Steer ................................................................................ 42 Figure 36: K&C Results: Longitudinal Braking – Toe Stiffness ........................................... 42 Figure 37: K&C Results: Lat Parallel – Toe Stiffness ............................................................. 43 Figure 38: K&C Results: Align Opposed – Toe Stiffness ...................................................... 43 Figure 39: Stamping Formability for 22MnB5 Main Beam Structure ................................. 45 Figure 40: Relative Cost Comparison ...................................................................................... 49 Figure 41: Relative Cost Comparison Plot.............................................................................. 50 7 Lightweight Twist Beam Development – Final Report List of Tables Table 1: Detail OEM Baseline Twist Beam Assembly Mass Summary .............................. 15 Table 2: Steel Sheet Material Properties .................................................................................. 27 Table 3: Performance Summary ............................................................................................... 37 Table 4: Detail Mass Summary................................................................................................. 39 Table 5: Assumed Material Costs ............................................................................................ 47 8 Lightweight Twist Beam Development – Final Report Purpose The objective of this project was to develop a lightweight steel proof-of-concept twist beam design that achieves a 15 to 25% mass reduction with equivalent structural and elasto-kinematic performance relative to the baseline design at a ≤ 10% cost premium. A current production OEM twist beam assembly was used to establish the baseline for package, performance, mass and cost. Figure 1: Baseline OEM twist beam assembly Conclusions The results of the study support the following conclusions: The U-Beam design is predicted to be 30.0% lighter than the OEM baseline design at a 12 to 15% cost premium at production volumes of 30,000 to 250,000 vehicles per year, respectively. The design is deemed production feasible based on expert manufacturing assessments. The S-Beam design is predicted to have the best strength performance at a 14.9% mass reduction relative to the OEM baseline design. The design is deemed production feasible based on expert manufacturing assessments. Recommendations The twist beam designs are driven by durability and strength requirements at the component level and elasto-kinematic requirements at the vehicle level. 9 Lightweight Twist Beam Development – Final Report Durability (Max Twist load case) and strength (Max Vertical load case) are the primary design drivers for both designs. CAE fatigue and strength modeling guidelines for the weld Heat Affected Zone (HAZ) have been developed based on Steel Market Development Institute (SMDI) recommendations. Currently, OEM best practices specify reduced material properties for all MIG welds and adjacent material in the weld HAZ to account for the effect of welding. Typically, the same reduced material properties are specified, regardless of the grade of steel. Some studies have shown that reduction in fatigue performance of advanced high-strength steel (AHSS) can be minimized by optimizing joint geometries [1]. Further study and development of robust high-volume welding practices and other advances in the area of sheet steel joining, especially with AHSS and ultra high-strength steel (UHSS) are recommended. Welding practices that result in improved HAZ properties could enable additional mass reduction by improving durability performance and thus more fully exploiting the benefits of high-strength materials in chassis components. Additionally, with the aggressive gage reductions enabled by the use of AHSS and UHSS, typical corrosion protection strategies may not be sufficient for these materials in chassis applications. Additional studies of the corrosion performance of these materials in welded assemblies, including pre- and post-assembly coatings, are recommended with the goal of developing definitive corrosion treatment strategies for chassis applications. Finally, although variable gage materials with gage differences up to 1.0 mm were considered and analytically assessed during the project, the final designs consist of constant-thickness components which meet the performance requirements. Additional studies of variable-gage components with smaller gage differences could be undertaken to investigate further incremental mass savings. 10 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Baselin ne Design n The baseeline design n, as chosen n by the SM MDI team, iss depicted iin Figure 2.. The main structure is compriised of a tub bular transv verse beam m and tubular trailing aarms extend ding from thee bushings to the damper mountss. Upper an nd lower reeinforcemen nts are addeed at the jointts between the transveerse and lon ngitudinal m members. T The transveerse beam features an inverted d “V” in cro oss section,, rotated fro om verticall orientation n. Each damper mount is in n single-sheear via a threaded sleeeve welded d to the long gitudinal tu ube. The spin ndle mountts are cantillevered abo ove the trailling arm tu ubes and incclude reinforceement platees, machineed for rear wheel w staticc alignmen nt. Figure 2: OE EM baselin ne design 11 Lightweight Twist Beam Development – Final Report Design Targets The overall project design targets are illustrated in the schematic shown in Figure 3. The objective was to develop a minimum mass design within the packaging constraints that met the structural and elasto-kinematic performance targets. Corrosion requirements are addressed by appropriate selection of material coatings, which typically do not add significant mass, but can increase cost. Mass and cost are the primary outputs of the study. 12 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figu ure 3: Twisst beam dessign targetss Structurral Perform mance The speccific structu ural perform mance requ uirements arre summarrized in the schematic shown in n Figure 4. The fundam mental design requireements are sstrength, du urability an nd elasto-kiinematic peerformancee (as demon nstrated by subsystem m-level Kinematic and Complia ance or K&C, perform mance). The strength requirrements incclude (5) qu uasi-static eextreme loaad cases in w which the tw wist beam may m not exhiibit more th han the allo owable perm manent set. The durab bility requirem ments inclu ude a total of o (16) load cases that m must be sattisfied. Only thee load casess that drivee the design ns will be diiscussed in this reportt. These include the top (3) ( extreme load cases and the top p (3) durab bility load cases. 13 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure e 4: Structu ural perform mance targeets Mass A high-llevel breakd down of the OEM baseline twist beam assem mbly mass is shown in n Figure 5. 5 The comp plete assembly mass off 24.9 kg, in ncluding bu ushings, is u used as the overall basis b for comparison of o the desig gns with resspect to mass. A detailled compon nent mass breeakdown fo or the twistt beam asseembly is pro ovided in T Table 1. 14 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Fig gure 5: Base eline twist beam assem mbly masss summary Table 1: Detail D OEM M baseline twist beam m assembly y mass sum mmary O OEM Baseline Twiist Beam Asy Mass per Asy C Component kg % of tottal S Seat-Spring 2.16 8.7% P Pipe-T/Arm Bush 0.70 2.8% B Brkt-Spindle, Rr Ax xle 2.15 8.6% B Brkt-Damper, Rr Ax xle 0.41 1.7% P Plate-Spindle, Rr Axle A 0.98 3.9% T Trailing Arm - Rr Axle A 7.39 % 29.7% B Beam-Rear Axle 7.26 29.2% % B Brkt-Parking Brakee Rr 0.16 0.7% W Welding-Rr Axle 0.33 1.3% R Reinf-Beam Upr 0.48 1.9% R Reinf-Beam Lwr 0.44 1.8% P Patch-T/Arm 0.07 0.3% P Pipe-Insulator 0.16 0.7% 22.71 % 91.2% 2.19 8.8% 24.90 % 100.0% T Twist Beam Asy lesss bushings B Bushings C Complete Twist Bea am Asy 15 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Package e The overall design environmeent and resu ulting availlable packaage space is illustrated in Figure 6. 6 The twist beam pack kage space is i defined b by the fuel ttank, the sp pare tire weell, the rear floor pan, the t tire env velope, the required r cleearances to o these com mponents an nd the requ uired twist beam b suspeension traveel. Figure F 6: Pa ackage volu ume and deesign envirronment on Corrosio The projject target for f corrosio on performa ance was baased on typ pical OEM ccorrosion requirem ments. Thesse requirem ments vary, but were asssumed to require a m minimum 10-year life in a hig ghly-corrosiive environ nment. Cost Recogniizing the ag ggressive weight w reducction targetts enabled b by the use o of AHSS an nd UHSS, th he project cost c target was w a ≤ 10% % increase rrelative to tthe OEM baaseline desiign. To assesss cost, the manufactur m ring cost was w estimateed for the seelected U-B Beam propo osal and com mpared to th he baseline design cost. The projject costing g assumptio ons were: Manufacturing cost for thee twist beam m assembly y including the structu ure and bush hings; 16 Lightweight Twist Beam Development – Final Report Production volumes of 30,000, 100,000 and 250,000 vehicles per year; and Program life of six years. 17 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Develo opment Process An itera ative optimiization strategy was used u to miniimize the m mass of each h design, w while meeting g the specifiied structurral requirem ments. A sch hematic of the overalll developmeent strategy y is shown in n Figure 7. The key eleements of tthe strategy y are discusssed in the followin ng sections. Figure e 7: Develo opment pro ocess diagraam ept Develo opment 1. Conce Initial deesign conceepts were developed d based b on sizze and shap pe optimizaation of the availablee design sp pace shown in Figure 6. 6 Stiffness aand strengtth-based to opology optimiza ation metho ods were used to iden ntify promissing concep pts using th he optistrucct solver [2 2]. Without manufactu uring constrraints, the o optimizatio on output w was a truss structure with a disstinct “U” shape s in pla ain view. T This result w was interpreeted into a s in Fiigure 8, nam med for its plan-view shape. concept “U-Beam” design as shown Various draw constraints werre also used d to identify y potential d design conccepts. The extruded d constrain nt that resullted in a seccond initial concept is shown in F Figure 9. Th his concept was termed d the “S-Beeam” since the t cross-seection deveeloped into an “S” shape as additional optim mization wa as performeed. 18 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure e 8: Volume e topology optimizatiion V top pology optiimization u using an exxtruded con nstraint Figure 9: Volume gn Develop pment 2. Desig A total of o two (2) ca andidate deesign conceepts were id dentified in n the concep pt developm ment stage forr further deevelopmentt. As indica ated in Figu ure 10, thesee were the U U-Beam an nd 19 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report the S-Beeam concepts. Various optimization strategiees were utilized to meeet each loaad requirem ment, whilee minimizin ng the overa all mass. Sh hape optim mization wass used to develop p the compo onent geom metry. Numeerous addittional desig gn iteration ns were conductted to fine tu une the ma aterial selection, thickn ness and loccal geometrry to meet strength h, durability y and elasto o-kinematicc requiremeents. The ellasto-kinem matic requirem ments were cascaded into i component twist b beam stiffn ness requireements allowing g for rapid early assessments in Abaqus A befo ore creation n of flex bo odies and fu ull K&C asssessments via v Adams. The U-B Beam design n was later selected ass the preferrred alternattive due to its superio or structural, mass an nd elasto-kin nematic perrformance. The S-Beam m design d details are also provided in this pa aper. Figure 10: Cand didate desi gn conceptts ufacturing and a Corros sion 3. Manu The man nufacturing g feasibility y of each design was asssessed at v various stag ges of the develop pment proceess. Additio onal design n developm ment was con nducted to meet manufaccturing feassibility requ uirements. Corrosion rrequiremen nts includin ng selection n of coatingss were conssidered as part p of the manufactur m ring feasibillity assessm ments. 4. Cost Assessme A nt The fina al step of the developm ment processs was to esstimate the manufactu uring cost fo or the seleccted U-Beam m design an nd the OEM M baseline d design. Pro oduction costing methodo ologies werre applied to t estimate the manufaacturing co osts for the U U-Beam design, and a the cossts were com mpared to the t OEM baaseline costt. 20 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Design n – Packa age Effectts Two dessign changees with systtem-level efffects were made to th he candidatte twist beaams relative to the OEM M baseline design: d nting strateegy will req quire attach hment of thee hub from the outboaard First, thee hub moun rather th han inboard d direction (similar to the Honda Fit or Ford d Fiesta dessigns as sho own in Figure 11). am example e with outb board-driveen hub fastteners Figure 11: Twist bea amper loweer attachmeent was mov ved 40 mm m outboard o on both dessigns Second, the rear da to facilittate a much h improved load path to t the beam m structure.. The movee maintaineed the tire clearance c en nvelope an nd resulted in i a dampeer motion raatio changee from 1.12 to 1.11. Thiis is illustra ated in Figu ure 12. 21 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 12: Damper atttachment for f OEM baaseline and d U-Beam d designs 22 Lightweight Twist Beam Development – Final Report Design Proposals The final U-Beam and S-Beam design proposals are shown in Figure 13 and Figure 14, respectively. U-Beam Design The U-Beam design utilizes UHSS and AHSS to enable aggressive gage and mass reductions. The U-Beam design features hot-formed tubular transverse and swept longitudinal members, all from 22MnB5 material with a constant 2.5 mm thickness. The transverse member has a closed inverted “U” cross section to provide the desired shear center location for roll steer performance. The roll steer can be tuned if required with this design by adding a rear-view sweep to the beam. The final design presented in this report has been tuned to achieve the OEM baseline roll steer with an unswept design for simplicity. The transverse member also features a fixed material gage but with a 20% increase in OD near vehicle centerline. This adds stiffness via section enlargement with minimum added mass. This increase in section is achieved either through the ACCRA® hot-forming process or by a purchased variable-diameter tube. The normally circular cross section of the longitudinal members is formed to a rectangular cross section at the hub mounts, facilitating integration of the hub attachment features without additional parts. A unique feature of this design is the addition of structural “bulkheads” to locally stabilize the beam assembly in the critical transition area from the lateral beam to the longitudinal arms. Trailing arms containing the bushings are simple inverted “U” profile stampings from DP780 material. All components are MIG-welded to form the assembly. 23 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Fig gure 13: U-B Beam desig gn concept S-Beam Design The S-Beeam design n features a hot-stampeed main beeam and an associated hot-stamped lower reeinforcemen nt, all from 22MnB5 material. m Th he stamped beam desig gn providees the “S” crosss section deerived from m optimizattion. The ov verall shapee of the beaam is also a “U” in the pllan view, reeflecting thee optimizattion results consistentlly observed d during develop pment. The S-Beeam also in ncludes bulk kheads to stabilize thee lateral-to-llongitudinaal beam transitio on area. aining the bushings b arre closed-seection tubullar compon nents from Trailing arms conta ® DP780 material, m alsso designed d to be com mpatible witth the ACCR RA hot-forrming proccess. All comp ponents aree MIG-weld ded to form m the assem mbly. 24 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Fig gure 14: S-B Beam desig gn concept 25 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Performance Finite element (FE) analysis methods m were used to p predict the structural p performancce of each dessign. The FE E model forr the two neew design cconcepts iss shown in Figure 15. 1 As menttioned prev viously, an iterative i op ptimization strategy w was used to minimiz ze the mass of each design while meeting th he specified structural requiremen nts. Optistru uct [2], Abaqus / Stand dard [3] and d nCode DeesignLife [44] softwaree products w were used to optimize an nd assess th he structura al performaance of desiigns. The fiinal design ural perform mance are d discussed in n the follow wing section ns. materiall selections and structu Figure 15 5: Twist Beam Finite E Element M Models Materia als For the U-Beam U and S-Beam designs, d thee material g grade selecttion was priimarily influencced by the durability d and a extremee load casess. Addition nal material selection criteria included i fo ormability, weldability w y, availabili ty and costt. A table su ummarizing g the Auto/Stteel Partnerrship team recommend ded sheet m materials is provided iin Table 2. ves for the sheet s and fo orged mateerials utilizeed in this sttudy Engineeering stress--strain curv are comp pared in Figure 16. Th he yield and d ultimate ttensile stren ngths are in ndicated forr each ma aterial. Fatig gue propertties were ob btained fro om [5]. 26 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Table e 2: Steel sh heet materiial propertiies Fig gure 16: En ngineering stress-straiin curve comparison 27 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Materia al Modeling g Considera ations Materiall processing g considera ations were taken into account in n the finite eelement modelin ng. Specifica ally, the effects of weld ding-inducced material property rreduction in the Heatt Affected Zone Z (HAZ Z) were inclu uded in thee durability y and streng gth load casses per the SMDI S team m’s recommeendations as a follows: For the dura ability load cases, mateerial fatiguee property reductionss of 20% in tthe weld w HAZ were w applieed for all hig gh-strength h, advanced d high-stren ngth and ultra-high u sttrength steeel grades [6 6]. To achiev ve the redu uced properrties, the K’’ parameter p of o the cyclic stress-straiin amplitud de curve waas scaled by y 0.8. The sstrain liife curve wa as not mod dified. This is i shown in n Figure 17.. For strength h load casess, material strength s red ductions of 20% in thee HAZ zonee were w applied d for UHSS S grades with ultimatee strengths g greater than n 800MPa. [6]. Shell welds were assign ned properrties corresp ponding to the lower-sstrength material m of the t two join ning compo onents. The shell weld thickness w was determined d by a weigh hted averag ge between the two com mponent th hicknesses. An exam mple of the durability modeling m of o the HAZ can be seen n in Figure 18. An examplee of the streength modeeling of the HAZ is illu ustrated in Figure 19. Fig gure 17: Ma aterial fatig gue propertty reductio ons – HAZ 28 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 18 8: HAZ – Durability D iimplementtation Figure 19: 1 HAZ – Strength S im mplementaation al Selection n Materia The matterials weree selected fo or each desiign based o on meeting all of the sttrength and d durability requirem ments, form mability considerationss and SMDII’s recommendations. The 29 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report resulting g material selections s and a gage are illustrated d in Figure 20 and Fig gure 21. Thee materialls for the OEM baselin ne design arre specified d in Figure 222. The OEM M baseline materiall grades aree labeled geenerically to o maintain OEM mateerial specificcation confiden ntiality. Based on n existing corrosion c gu uidelines, a nickel-plaating coating g process iss recomm mended for the t U-Beam m in consideeration of itts componeents at <2.0m mm gage (ssee Figure 20). 2 An apprropriate E-ccoat finish is also reco ommended for both th he U-Beam aand the S-Beeam (see Fig gure 21) dessigns. Fig gure 20: U--Beam design materiaal selection and gage 30 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 21: S-Beam desig gn materiaal selection and gage Figurre 22: OEM baseline design d mateerial selectiion and gag ge 31 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Durabiliity The pred dicted dura ability life performanc p e is comparred in Figu ure 23 for all designs. T The minimum life values are show wn for the worst w case ((3) load casees. For each h design, th he ase loading results from m the Max Twist even nt. The asso ociated life ccontour plo ots worst ca are show wn in Figurre 24 for thee OEM baseeline design n, Figure 255 for the U-B Beam desig gn, and Figu ure 26 for th he S-Beam design. In all a cases, th he limiting llocation of each design n is the transsition area near n the latteral-to-lon ngitudinal trransition off the main b beam structture. In all casses the area a of low lifee occurs in the t parent m material ratther than in n a weld. Note tha at in Figuree 24, the OE EM baselinee predicted design life is 0.18, sign nificantly leess than thee 1.0 life min nimum targ get. When this t result w was first ob bserved, inv vestigationss into poteential causees began. Multimatic M performed p coupon tessting from p production OEM ba aseline twist beam parts to measu ure as-form med materiall propertiess and comp pare them to the publish hed values for the tran nsverse bea m materiall. While theese materiall propertiies roughly doubled th he predicted d life, the reesults weree still well b below the 1.0 life targeet. After furrther consu ultation with h the OEM M, it was dettermined th hat internal OEM prredictions closely boun nded the 0.1 18 life resullt, and conssequently, tthe OEM agreed to t use 0.18 lives l as the target for the t max twiist load casse. Figure 23: Predicted d durability y life compaarison 32 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figu ure 24: Pred dicted OEM M baseline design durrability lifee Figure F 25: Predicted P U-Beam U dessign durabiility life 33 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure F 26: Predicted S--Beam Desiign Durabiility Life e Loads Extreme The pred dicted perm manent set performanc p ce is compaared in Figu ure 27 for alll designs. T The permaneent set valu ues are show wn for the worst w case (3) load casses. In each h case, the w worst case load ding is from m the maxim mum verticcal event co ondition. Th he U-Beam and S-Beam m both meeet the 1.0 mm m maximu um set requ uirement ass measured d at the wheeel center, w with the S-Beeam exhibitiing the bestt overall strrength perfformance. The asso ociated plasstic strain contours forr the maxim mum verticaal event aree shown in Figure 28 2 for the OEM baselin ne design, Figure F 29 fo or the U-Beaam design aand Figure 30 for the S-Beam S desiign. The pla astic strain contours aare contoureed to 1.00% % for visualiza ation. 34 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure e 27: Prediccted extrem me load perrmanent sett comparison Figure e 28: Predicted OEM baseline b exttreme load d plastic strain 35 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 29: Predictted U-Beam m design exxtreme load d plastic strrain Figure 30: Predictted S-Beam m design exxtreme load d plastic strrain 36 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Perform mance Sum mmary The rela ative structu ural perform mance of ea ach design iis summariized in Table 3, wheree the relative performance is defineed as the acttual perform mance norm malized by y the indicatted target va alue. To meeet the requ uired level of o durabilitty performaance, the relative valuee must be ≥ 1.0, whilee the relativ ve value forr permanen nt set due to o extreme lloads must be ≤ 1.0. Th he primary and a second dary design n drivers forr each desig gn are iden ntified in thee table. Alll of the dessigns are prrimarily fattigue limiteed by the m max twist loaad case. A seconda ary design driver d for th he OEM basseline and U U-Beam deesigns is thee max verticcal event strrength load d case. Finally, both th he U-Beam aand the S-B Beam design ns are furth her limited by b the max cornering event dura ability case. Table 3: Perfformance ssummary 37 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Mass The fina al twist beam m assembly y mass resu ults, includiing bushing gs, are compared in Fiigure 31. The results r indiicate that th he mass of the t U-Beam m design is 330.0% less tthan the OE EM baselinee assembly mass, m whilee the S-Beam m design iss 14.5% ligh hter than th he OEM baselinee. The fina al twist beam m welded structure s mass m results are compaared in Figu ure 32. The results in ndicate tha at the mass of the U-Beeam structu ure is 32.8% % less than tthe OEM baselinee mass, while the S-Bea am structurre is 15.9% llighter than n the OEM baseline. The deta ail component masses are summa arized in Taable 4. Figure F 31: Twist T beam m assembly y mass com mparison 38 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 32: Twist T beam m structuree mass comp parison Table T 4: Dettail mass su ummary 39 Lightweight Twist Beam Development – Final Report Elasto-Kinematic Performance A key aspect of the development project was to closely match the OEM baseline elastokinematic behavior. Unlike many other suspension components, twist beam axles are designed to exhibit significantly compliant behavior. This behavior is typically measured by industry-standard kinematics and Compliance (K&C) testing. An Adams [7] model of the OEM baseline twist beam was created so that the K&C response of the proposed designs could be compared to the baseline design. First, flex bodies for the baseline twist beam were generated based on mesh created for structural analysis. Next, the Adams model was refined with the following information provided by the OEM: Spring rate / Spring preload at Design position; Jounce / rebound bumper stiffness; Bushing stiffnesses; Tire stiffness; and Tire unloaded radius. Once the initial Adams model was complete, the response of Adams K&C simulations were correlated with physical K&C test results. To further improve the correlation, bushings from a current production OEM baseline twist beam were obtained, the stiffnesses were measured as-installed in the beam, and the measured stifnesses were incorporated into the Adams model. A subset of the K&C plots for the selected U-Beam design and OEM baseline twist beam are presented here as Figure 33-Figure 38. The U-Beam closely matched the OEM baseline K&C characteristics, thereby providing confidence that the on-road vehicle ride and handling behavior of the two beam designs would be very similar. A full set of K&C plots is included in this report as Appendix 1: Kinematics and Compliance Plots. 40 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 33 3: K&C ressults: bouncce – bump steer Figure 34:: K&C resu ults: bouncee – bump camber 41 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figurre 35: K&C results: rolll – roll steer Figurre 36: K&C results: lon ngitudinal braking – toe stiffness 42 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure 37: K&C resullts: lat paraallel – toe sttiffness Fiigure 38: K&C resultss: align opp posed – toe stiffness 43 Lightweight Twist Beam Development – Final Report Manufacturing Each design was assessed to ensure manufacturing feasibility. Assessment included a combination of expert engineering and manufacturing experience, including input from partner companies on hot forming processes. Additional design development was conducted in some cases to improve manufacturing feasibility. U-Beam Design The main manufacturing considerations for the U-Beam design were the feasibility of forming the 22MnB5 transverse tubular member and the swept longitudinal members that join the transverse member and provide the spindle mounting structure. The 20% increased length of line near the centerline of the transverse tube is achieved either through the Multimatic / Linde+Wiemann ACCRA® hot-forming process or by a purchased variable-diameter tube. Both options were assessed by internal and external manufacturing experts to confirm feasibility. The “U” cross-section of the transverse beam is also achieved via the ACCRA® hotforming process. The swept longitudinal members include a 90° bend which was judged feasible by manufacturing experts. The bulkheads are sub-assembled to the transverse member during the beam assembly. A formed shoulder on the bulkheads is recommended to provide location and self-centering on the transverse tube. The remaining stampings are judged feasible based on the observation that the individual twist beam components are simple stamped and / or blanked components for which the trim lines can readily be developed and without major draw or other geometric limitations. The overall beam assembly was evaluated for weld access and judged feasible. Weld length for this design is 5980mm. S-Beam Design The main manufacturing considerations for the S-Beam design were the feasibility of the 22MnB5 main beam stamping and feasibility of MIG welding the assembly in production. To evaluate the stamping feasibility of the main beam, a hot-stamping supplier partner was consulted to evaluate the design. Expert review revealed no concerns. In addition, a one-step forming simulation was conducted to assess formability. Based on the results of the forming simulation shown in Figure 39, the main stamping is judged feasible. 44 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report The rem maining stam mpings are judged feasible based d on the obsservation th hat the individu ual twist beeam compon nents are siimple stam mped and / or blanked d componen nts for whicch the trim lines can reeadily be deeveloped an nd withoutt major draw w or other geometrric limitatio ons. a was evaluateed for weld d access and d judged feaasible. Weld d The overall beam assembly or this design is 8510m mm. length fo 9: Stampin ng formabillity for 22M MnB5 main n beam stru ucture Figure 39 45 Lightweight Twist Beam Development – Final Report Corrosion To meet OEM corrosion requirements, corrosion protection is generally applied to components based on material gage. The sheet steel material gage limit is OEM specific, and is assumed to be 2.0 mm for the purpose of this study. Typical requirements on a component basis are as follows: Gage > 2.0 mm: E-coat finish required. Gage < 2.0 mm: Hot dipped galvanized coating + E-coat finish required. The specific type of galvanized coating is also OEM specific. Examples of coating specifications include Hot Dip G60 / G60 (GI) or Hot Dip Galvanneal A-40 (GA). For a complex welded assembly such as a twist beam, if components are included below 2.0mm gage, the manufacturing recommendation from this study is a zinc-nickel plating process after assembly followed by E-coat. This is a current production process and eliminates manufacturing concerns by ensuring common welding processes for all components. The project also included consulting with the Auto/Steel Partnership Lightweight Chassis Corrosion Project Team on corrosion countermeasures for the beam designs. This team plans to conduct a build and test program to gather data on the corrosion performance of AHSS and UHSS with various treatments. Possible approaches include: Powder coating weld areas; Mild alloying of materials via added copper or chrome; and Post-formed coatings, especially for hot stamped boron steels. 46 Lightweight Twist Beam Development – Final Report Cost Estimates Production costs were estimated for the OEM baseline and selected U-Beam designs based on the SMDI-provided project assumptions. All costs are reported relative to the functionally equivalent OEM baseline design for comparison purposes. Costing was completed using Multimatic’s proprietary production cost estimation methodology. Assumptions The following assumptions were used to estimate the cost of the twist beam structure for the OEM baseline and the U-beam designs. Material Costs Sheet steel material costs were based on published data for the period of June 2013 to July 2013, with the exception of DP780 and Mn22B5 costs, which are based on data from material suppliers. The costs are summarized in Table 5. Table 5: Assumed material costs* Material Type HSLA 550 CR, 1.5mm HSLA 550 HR, 2.6mm HSLA 300 HR, 2mm SPH590 HR, 1.5mm HSLA 550 HR, 3mm DP780, 1.8mm Mn22B5, 2.5mm $CDN/lb $0.4969 $0.5050 $0.4642 $0.5244 $0.4948 $0.6284 $0.6553 $US/kg $1.0952 $1.1130 $1.0231 $1.1558 $1.0905 $1.3850 $1.4443 Design * OEM baseline design: Content included the welded assembly and the bushings (Figure 1). E-Coat finish included. U-Beam design: Content included the welded assembly and the bushings. Nickel plate and ECoat finish included. CRU Index for steel costs, June 12, 2013 - July 10, 2013, except for DP780 and Mn22B5 47 Lightweight Twist Beam Development – Final Report Program Production volumes of 30,000, 100,000 and 250,000 vehicles per year were evaluated. Program life: six years Variable Costs The following were considered in estimating the variable costs: Material blank size; Material type and coating; Plating and / or E-coating; Purchased components (bushings, etc.); Machining labor and burden; Variable overhead; Capital equipment; and Selling, General & Administrative Expense (SG&A). Fixed Costs The following were considered in estimating the fixed costs: Tooling (machining, stamping, welding, etc.); and Fixed overhead. Component Costs The total component costs were calculated from the sum of the variable and fixed costs, with the fixed costs calculated on an amortized basis. For comparison, only the total costs for each design are reported as costs relative to the baseline design cost. Cost Comparison Component costs were estimated as a function of production volume based on the above-mentioned assumptions. The relative cost results are summarized in a bar chart in Figure 40, where the cost basis for the comparison is the cost of the baseline at the indicated volume. The relative cost results are again plotted in the graph of Figure 41. However, in this case, the cost basis is the cost of the baseline design at the highest production volume (250,000 vehicles / year). The relative percent cost difference between the U-Beam design and the baseline is also indicated in Figure 41. The cost results indicate that the U-Beam design has a 12% higher cost compared to the OEM baseline at the lowest production volume and a 15% higher cost at the higher production volumes. Further, the results in Figure 41 indicate the relative change in the baseline cost as a function of the production volume. 48 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figu ure 40: Rela ative cost ccomparison n 49 Lig ghtweight Twist T Beam m Developm ment – Fin nal Report Figure e 41: Relativ ve cost com mparison plot 50 Lightweight Twist Beam Development – Final Report References 1. Anderson, D., Sang, J, “Effects of Material Properties and Weld Geometry on Fatigue Performance of DP780 and Mild Steel GMAW Lap Joints,” Great Designs In Steel 2009, www.autosteel.org. 2. Altair HyperWorks 11 Optistruct User's Guide; 1990-2012 Altair Engineering, Inc. 3. Abaqus Analysis User's Manual v6.11; Dassault Systèmes Simulia Corp, 2011 4. nCode DesignLife 8.0 User's Manual; HBM United Kingdom Limited, 2012 5. Material Fatigue Properties, OEM proprietary document, April 23, 2013 6. Lightweight Twist Beam Team Recommendation, Southfield, MI, March 22, 2013. 7. MD ADAMS 2010 Installation and Operations Guide, MSC.Software, 2010 51 Lightweiight Twist Bea am Developme ent – Final Re eport A Appendix 1:: Kinematics s and Compliance Plots s 52 Lightweiight Twist Bea am Developme ent – Final Re eport 53 Lightweiight Twist Bea am Developme ent – Final Re eport 54 Lightweiight Twist Bea am Developme ent – Final Re eport 55 Lightweiight Twist Bea am Developme ent – Final Re eport 56 Lightweiight Twist Bea am Developme ent – Final Re eport 57 Lightweiight Twist Bea am Developme ent – Final Re eport 58 Lightweiight Twist Bea am Developme ent – Final Re eport 59 Lightweiight Twist Bea am Developme ent – Final Re eport 60 Lightweiight Twist Bea am Developme ent – Final Re eport 61 Lightweiight Twist Bea am Developme ent – Final Re eport 62 Lightweiight Twist Bea am Developme ent – Final Re eport 63 Lightweiight Twist Bea am Developme ent – Final Re eport 64 Lightweiight Twist Bea am Developme ent – Final Re eport 65 Lightweiight Twist Bea am Developme ent – Final Re eport 66 Lightweiight Twist Bea am Developme ent – Final Re eport 67 Lightweiight Twist Bea am Developme ent – Final Re eport 68 Lightweiight Twist Bea am Developme ent – Final Re eport 69 Lightweiight Twist Bea am Developme ent – Final Re eport 70 Lightweiight Twist Bea am Developme ent – Final Re eport 71 Lightweiight Twist Bea am Developme ent – Final Re eport 72