A new era Accelerating toward 2020

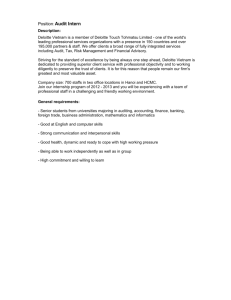

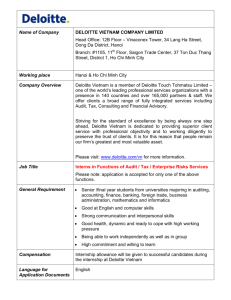

advertisement