Compensation for Rotor Position Estimation Error

advertisement

Compensation for Rotor Position Estimation

Error due to Cross-Coupling Magnetic

Saturation in Signal Injection Based Sensorless

Control of PM Brushless AC Motors

Z. Q. Zhu, Y. Li, D. Howe, and C. M. Bingham

Department of Electronic and Electrical Engineering, University of Sheffield, Mappin St., Sheffield SI 3 JD, UK

although the problem was not fully studied or solved. Recently,

it was established in [7] [8] that the error was caused by the

effect of cross-coupling magnetic saturation between the d- and

Abstract- This paper proposes a simple method for reducing

the rotor position estimation error caused by cross-coupling

magnetic saturation between the d- and q-axes when signal

injection based sensorless control is applied to a brushless AC

(BLAC) motor. The error in the estimated rotor position, which

results when conventional signal injection sensorless control is

employed, is analyzed. Based on an improved model of a BLAC

motor which accounts for the influence of dq-axis cross-coupling

on the high-frequency components of the incremental winding

inductances, as deduced by either finite element analysis or from

(i.e.,

Ldqh#O),

and was influenced by the machine

design, but, as yet, no measures, from the control aspect, have

been proposed to reduce the error. Nevertheless, it is well

known that a mutual inductance exists between the d- and qaxes of a BLAC motor (Ldqh) as a result of cross-coupling due to

magnetic saturation, as shown in [9], both experimentally and

by finite element analysis. However, for simplicity, the

.

measurements, an improved signal injection based sensorless

scheme is proposed. Its effectiveness is demonstrated by

nfluence of

.

. '

cross-coupling magnetic

.

.

saturaton1S

usually

neglected in sensorless rotor position control [1-6].

This paper improves the rotor position estimation accuracy in

a signal injection based sensorless control scheme by

accounting for the influence of cross-coupling due to magnetic

saturation. Section II presents an improved model of a BLAC

motor which accounts for the influence of the cross-coupling.

Section III analyzes the position estimation error which arises

when cross-coupling is neglected, and proposes a simple

method of reducing the error, based on either predicted or

measured

incremental

inductance

characteristics.

Measurements are presented in section IV which validate the

effectiveness of the proposed method.

measurements on a BLAC motor having an interior permanent

magnet rotor.

I. INTRODUCTION

It is necessary to acquire rotor position information for a

permanent magnet (PM) brushless AC (BLAC) motor in order

to control the 3-phase stator currents, and, hence, the torque.

Generally, either an encoder or a resolver is employed.

However, such discrete position sensors not only increase the

system complexity and cost, but may also compromise the

reliability. It is desirable, therefore, to estimate the rotor

position indirectly from the terminal voltages and currents.

Sensorless methods based on high frequency signal injection

exhibit excellent rotor position estimation performance at

standstill and low speeds, when back-EMF based sensorless

methods are problematic. The most common high frequency

signal injection method uses a sinusoidal carrier voltage signal.

It was originally developed for use with induction motors, but

was subsequently applied to PM BLAC motors with geometric

saliency [1-5]. The identification ofthe initial rotor position was

obtained in [4] [5] by comparing sine and cosine terms in the

2nd_order harmonic component in the d-axis current. In [6], it

was applied to a non-salient BLAC motor equipped with a

surface-mounted PM rotor, by utilizing the saliency effect

which was caused by magnetic saturation.

However, it was found experimentally in [2] that the error in

the estimated rotor position increases with the load current,

1 -4244-0743-5/07/$20.OO ©2007 IEEE

axes,

q-

I. ANALYSIS OF CROSS-COUPLINGEFFECT IN BRUSHLESS AC

MOTOR

For a 3-phase BLAC motor, the phase voltages, va, vb, and vc

are given by:

Fval

b

VC

_ic_

/bdt

ldt

(1)

where ia, ib, ic, I/a, VIb and qfc are the phase currents and

flux-linkages, respectively, and Rs is the stator winding phase

resistance. Since the 3-phase flux-linkages are functions of the

phase currents and the rotor position, 0Sr, (1l) can be expressed

as:

208

0ava

0aa

aa

dia V

ai| dt

Vb dib

a1a

13iadt

0

fLah

V/a dO,

=

[V a(ia+Ail,b, icAl) - VJa(ia, ib,h li, m)]/Ai

00a dt |Labh = IV a(ilaIb+A4iIc,).

mr) Va(lalb ,Ici,m)]/Ai

0b

aVb

+ ayl,b

aob dObI

Vb = Rsi5b + a_

dt

where Ai is an incremental current, and the influence of the

LVCJ j

I

permanent magnet flux, Dm, on the magnetic saturation is

C

dic

,C

C

a c dOc (2)

alaei

&3ib

&3i jdt

aoOc dt

considered in the finite element calculation of ql,.

aia O'b

oic

Since the incremental phase self- and mutual-inductances are

|-ial

-Es (Oa)

La7h Labh Lach ia

functions of the rotor position, 0r, the terms in the incremental

=Rs ib + Lbah Lbh Lbch P ib + CWr -Es (0,b)

inductance matrix are given by:

LI~~ I!Lcah

cbh

~~~~jJ)lP!bl

+

L-EjOj~~~~~~

Lcbh Lch

FLah =L)ah(or)

[Labh=La ab -;T

where Lah, Lbh, and Lch, and Labh, Lbch, Lcah, Lbah, Lchh, and Lach are

Lbh Lah (Or -227 / 3), Lbch =LCbh Labh (or -i) (8)

the phase incremental self-inductances and incremental

LLch =Lah (Or +2;T / 3) LLcah =Lach =Labh (Or+7iT/3)

mutual-inductances, respectively. Oa Ob, and Oc are the position

of the phase windings relative to the rotor, and defined as: Oa=6r,

The d- and q-axis incremental self- and mutual-inductances

Ob=Or-22t/3, and Oc=Or+2±lt3, and Es is the phase EMF. In a signal may be determined approximately from the phase inductances

injection based sensorless control scheme, only the high using (6). By way of example, typical finite element calculated

frequency terms in (2) are considered [6], i.e.:

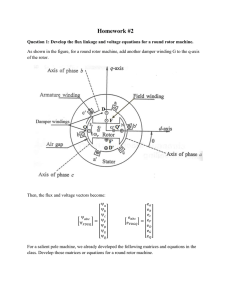

magnetic field distributions on both open-circuit and at rated

load for the machine under consideration are shown in Fig. 1,

~Vahl

rah 'abh ach 1 Flahl

and corresponding phase incremental self- and

(3) mutual-inductances, Lah and Labh, and d- and q-axis incremental

Vbh L=|'bah Lbh Lbch IP ibh|

Vch

Lcah Lcbh Lch Jch

self- and mutual-inductances, Ldh, Lqh, Ldqh, and Lqdh, are shown

in Figs. 2 and 3, respectively. The direct calculation of d- and

where Vah, Vbh, and Vch, and iah, ibh, and ich are the high frequency q-axis incremental self- and mutual- inductances will be

components of the phase voltages and currents, respectively, discussed later.

and p=d/dt. Equation (3) can be transformed into the dq-axis

reference frame as:

Fva 1

?ia

Fl 1

a

alb

a

0

I_C LLCah

LL?dh

LiC

ah

Lq

ach

abh

bah

Lda L cbh

L*iL|td

-LEs (O}C)

I

bch

ch ]C

hLl

asF

dh

h.

(4)

P'~qh~

Lqdh Lqh

where C is the 'Park' transformation matrix, and Ldh, Lqh, Ldqh

and Lqdh are the d- and q-axis incremental self- and mutualinductances, i.e.:

Fcosa0.-sinO 11

C

cos

Ob

-sin Ob 1

Lcos Oc -sinOc

L

~

L

dhdqh

1

~

~

Ldqh j

which-1

Lah and Labh

are

ahL abh

Lah

~~Lcah

can

griven

(5)

1ij

L

in

L h

ac

Lcb,h0~~~~~~~~0

Lch

whifle

flu-irv1nkages

be determined according to the

(7),

L6[=L P(Or 3)

L L(

dh

Lih

La and Lcah cbh

Ldh Ldqh *1

dt

thep

definitions

can

beP

R

a_

(a) Open circuit, id-OA, iq=OA

As Lah and Labh in Figs. 2(a) and 3(a) vary periodically with

the rotor position, 0r, they can be expressed approximately as a

Fourier series, i.e.:

60

E

o0

cs

50

-------------------------------------

30/\

20

-a

-J -k =i,2,3,

Io

a:

Ea) -10

o: -30

-30

I

50

,

40

120

18

0R60t12

180

240

300

240

300

Rotor position (elec. Deg.)

(a) Incremental phase self- and mutual-inductances

60

E

60

L-

20

- 1-0---a)

30

(a5kcos kOr+ b5ksin kOr)

{Labh(O:)= amo+

(ankcosk+bmksinbk,

(9

)

k1,2,3,

where a5o, amo, a5k, b,k, amk, and bmk are the amplitudes ofthe DC

terms and the kth-order terms ofthe Fourier series, respectively.

Since the amplitude of the high order harmonics in Lah and Labh

is relatively small, only terms up to k=8 are considered and

transformed from 3-phase to dq- values using (6) and (7). The

average values of Ldh, Lqh, Ldqh and Ldqh are calculated from:

360

36

L qh

cu

=a5+

E

Sah(Or)

30

sx5

[Ldh

=(a,0-a 0)+(a 12+a )

[-(LsOhmOd+

{ Lqh = (as0 -amo) (as2/2+am2i)

2

Ldqh

Lqdh

m2

(10)

(bs2/2+bm2)

L dqh

As well be evident from (9), the saliency which results in a

BLAC motor equipped with an interior magnet rotor, Ldh#cLqh, is

caused by 2nd order co-sine terms, a52, am2, in the Lah and Labh

0

60

120

180

240

300

360

waveforms, which are considered in [10]. The cross-coupling

Rotor position (elec. Deg.)

effect is caused by 2nd order sine terms, b52, bm2, in the Lah and

Labh waveforms, which are usually neglected [10]. In

(b) Incremental dq-axis inductances

Fig. 2. Incremental inductances on no-load, iOA,iq=OA.

subsequent equations, Lqdh is written as Ldqh. It can also be

shown that the 5th and 7th order terms in Lah and Labh, i.e., as5,

60

E 50

bs5, aL7m5, as7, bs7, am7, and bm7, cause the variation of Ldh, Lqh,

40and Ldqh with rotor position every 60 elec. deg.. Other order

w

40 -harmonics in Lah and Labh do not appear in Ldh, Lqh and Ldqh, as a

an 30 Jr

La

o 20

result of (6).

l0

Although the d- and q-axis incremental inductances can be

Labhdetermined by transforming the waveforms of the incremental

5FU

a) -10 t

phase self- and mutual-inductances, Lah, and Labh, into the

/

2

<

a)

dq-axis reference frame, this requires the flux-linkage, Vla, of

__

_

_

_

_

_

_

phase a to be calculated for various d- and q- axis currents and

rotor positions, which is time consuming. To reduce the finite

0

60

120

180

240

300

360

element calculation time, the incremental d- and q-axis

Rotor position (elec. Deg.)

inductances can be calculated directly from d- and q- axis

nmflux-linkages by applying appropriate d- and q-axis currents in

60

the finite element analysis, equation (l1). Results calculated

E 50

4

I Lqh

a)

40

directly in this way are shown in Fig. 4.

Ldh =[d(id+ Aid, i, qm

=l

au 30

iddiq, m)] | Aid

dh

=

-,

LqdLL,h

Aiq, (D )-Vfqd(Id,ITm]/q

(id,iq, D )]/Aiq

[yfq (id I'q' ++ITm)VJ

=[V~d('d

~~~~~~~~~~~~dqh

0

X

E -10

o -20

-30

-

bm5,

-

-1

-------------------------

-------------------

-_1

-_

E

-10

L

--

o

--

0

60

120

180

240

Rotor position (elec. Deg.)

-Ld-tJ-(id- + Ai+d,Aiqn iq, O(mm )- q (dniq,iq, Dn/tm)/ AidAiq

d41h

-di -4(

-Li

300

,

-M c (/

O),, )

various d- and q-axis currents, id and 'qn the d- and q-axis

incremental self- and mutual-inductances, Ldh, Lqh, Ldqh, vary

with the d- and q- axis currents because of saturation. For the

360

(b) Incremental dq-axis inductances

BLAC motor under consideration, Fig. 1, Ldh Lqh and ldqh are

Inrmetlinutncsonfl-q

Fig.3.

210

FVe 1

FLdh Ldqh- -1

FVdh1

Fl

T

I e =T(AO)

P

.e

=T(AO) L

(AO)

Z

dqh

qh

Vqh

j

-1qhj

LVqh

12

Lavg -Ldjcos(2AO+Om)

Ldjesin(2A0+Om (1Fi

25mH, 32mH and -7mH, respectively, when iL=OA and iq=4A.

Clearly, since the magnitude of Ldqh iS comparable with that of

Ldh and Lqh, its influence cannot be neglected in the high

frequency voltage equations.

L

60

£ 50

--

(usss 40

0

-a

-C

X

^

*

*

*

*

cos(AO) sin(AO)

j $ "== 8_ -_ T(AO)=

Id=1A -sin(AO) cos(AO)

i

30

@I d=OA

*

*

Lavg (Lqh+Ldh)/2, Ld =(Lqh-Ldh)2

hL2(

-4- Id=-IA

>~

-

+

+

E 2()

-i

Lno2

I d=-2A

-4

-3

1

-1

0

2

3

q -axis current (A)(a) d-axis incremental inductance, Ldh.

-2

(13)

i

Ldif

+

dif+Ldqh

4

q-aisc

=

)Vsig

avg-Ld

cos(2A0+Om)

Ldif sin(2AO+Om)

0

1iLh1

P

p

Ldif sin(2AO+Om)

Lavg+Ldif cos(2A0+Om) IqhL

The resulting d- and q-axis high frequency currents in the

E-US

a)~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~(4

Id=3A

c40

estimated reference frame are obtained by solving (14):

r 30 | _

_q |

20

3 l()

evSi

d=O~

IA )[Lag +Ld cos(2AO+O,m)]

sig2~ ~ ~IL2

+~~~~~~

--Id:-1A

| dh

1

___

-4

15

___

-,3

o

l'h

___

-2

___

-t

___

0

___

1

q--axis current (A)

___

2

___

3

4

E'

0

E

0t

------------4_

dif)

Ldj sin(2A0+Om,)

the estimated rotor position as a result ofthe incremental mutual

inductance, Ldqh, which exists between d- and q-axes. The error

-Id=2A

-~~~~~~~~~~~~~~~

L

signal injection based sensorless schemes [6], an error exists in

Id=3A

5

,avg

Thus, ifthe high frequency component in the q-axis current is

controlled to be zero, i.e. iqhe=O, as was in the conventional

isgivenby:

+Id=1A

()--------

o

-i

P('

L

(b) q-axis incremental inductance, Lqh.

10

I_,

-4a)

hd)

Since the high frequency sinusoidal voltage, vsig, is applied to

the estimated d-axis, i.e., Vdhe=Vsig, VqhOe=0 (12) becomes:

60

£

(

Om =arctan(Ldqh/Ldf),

Id0-3A

C:

0

Iqh j

where AO=Ore_Or is the error in the estimated rotor position, and

Id=3A

-_ Id=2A

I_,

Lavg+Ldif cos(2AO+Om)j

Ldif sin(2AO+Om)

~~~d-A2

-4Id30A

Id=-2A

I d=O

0

1

60-m

(

2Lh

(16)

Ldh -Lqh

2

-rca

|-

Idd=-3A 6T

Id= 3

0~~~~~~~~~~~~~~~

a)d -xlm

-1 mcrmeta

0

-4 -3 -2 ta

q-axis currentt (A)

a)

3

4 21

------

o

------

0

60

a)

o( 0 3 500

andq-axiscurrents.~

~ incremental

~ ~ ~~~~~~~~~~

C

inductance, Ldqh=Lqdh.

(c) dq-axis mutual

o a)

.p

4.

Variation

of

incremental

selfand

mutual-inductances

with

dFig.

dq-axis

-_F

and q-axis currents.

O01

0_

III. ANALYSIS OF ROTOR POSITIoN ERROR CAUSED BY

CROSS-COUPLING

transformed into the estimated rotor position, Ore, i.e.:

211

_

_

0

--------0

0element

ed=OA0

_+ d O

+I d=2A

_

60

45

.0

co

30

l

215

E

.o

a)

oo

0

sampling, the speed control loop, and the PWM are all set to

5kHz, and the injected signal is 35V, 330Hz. The actual rotor

position, 0r, is obtained from a 1024 pulse-per-revolution

encoder, which is used as a reference for the estimated rotor

position Ore. The rotor position error compensation factor, Kr,

was Kr=8.0 '/A, as obtained from the experimental results given

in Fig. 5(b).

i- Id 3A

-

-4---I-----I d= 2A

Id=

-

lA

Id=O A

0~~~~~~~~~~~~~~d1

lA

-Id

--d2

15

O

ow

-----

o ° 30

Id=3A

-

,Lv cl

45

1)

60

4

3

2

1

0

1

q-axis current (A)

2

3

4

(b) Directly measured error, Kr8.00/A.

P11)

--

Fig. 5. Comparison of predicted and measured rotor position estimation

for various d- and q-axis currents.

A1AC

id

error

to

I

Clearly, the error in the estimated rotor position will only be

when Ldqh=O. The stronger the cross-coupling between the

d- and q-axes, the larger will be the error in the estimated rotor

position. For the BLAC motor under consideration, the

variation of the predicted error with the d- and q-axis currents is

zero

AC

..sed

shown in Fig.5(a), the predictions being obtained by employing

iie element

lmn cluaediceena

Fg

theth

finite

calculated incremental inductances,

Fig. 4,,iin

(16).

The error in the estimated rotor position has also been

measured by driving the BLAC motor with the actual rotor

position obtained from a precision encoder, so that id=id, and

6. Signal injection sensorless control with compensation for rotor position

Fig.

error due to cross-coupling.

nucacs

Iqe=iq. The high frequency voltage

was

60

°6-

45

--

E)& 315

injected into the

estimated d-axis, and the estimated high frequency q-axis O 2

°a

current, iqhe, was forced to zero by adjusting the estimated rotor

The

measured

rotor

estimation

position, OrU.

directly

position

error is shown in Fig. 5(b), which compares well with the

o

predicted results shown in Fig. 5(a).

ry

IV. COMPENSATION OF ROTOR POSITION ERROR DUE TO

CROSS-COUPLING AND COMPARISON WITH CONVENTIONAL

METHOD

The error in the estimated rotor position can be compensated

for by either employing (16) or using the results shown in Fig. 5.

However, from both the predicted and measured results shown

in Fig. 5, it can be seen that the error in estimated rotor position

is approximately proportional to the q-axis current, i.e. AIO.Kriq.

Thus, the error can simply be compensated for according to the

q-axis current, i', by applying a compensation factor, Kr This

significantly simplifies the implementation of an error

compensation scheme.

The proposed sensorless control scheme is shown in Fig. 6,

and the parameters of the interior permanent magnet motor,

whose incremental inductance characteristics were shown in

Figs. 4 and 5, are given in Table I.

The control strategy is implemented on a TMS32OC3 1 DSP,

together with a PIC 1 8F443 1 MCU, which serves as the PWM

generator and the encoder interface. The frequencies of the AD

212

-

0

Id=3A

lA

--Id=O

-4Id=2A

' 15

-

30

1~~~~~~~~~--d=3A

*

-6-

-45

-

-60

-4

60

0

-1

1

2

3

4

q-axis current (A)

(a) Conventional method, RMS(Ore-Or)=21. 10

-3

-2

4

.

c

E& 30

ag

-

iId=-lA

15

o ° °Id=OA

15

o

-

Q-

1

-- Id=lA

-Id=2A

3

--Id=3A

0

t

Fig. 7.

-45

-60

Id=-2A

-

-4

-3

-2

-1

0

1

2

3

q-axis current (A)

(b) Proposed method, RMS(Ore~Or)=3.2°

Measured rotor position estimation error with

proposed signal injection based sensorless methods.

4

conventional and

the rotor speed command is changed from -1OHz to +1OHz, i.e.,

-200rpm to +200rpm. As will be seen in Fig. 8(a), when the

conventional signal injection based sensorless scheme is

employed, the estimated rotor position error increases

significantly with the load current, and is 250 when iq=4A. By

applying the proposed error correction method this reduces to 50,

TABLE I

SPECIFICATION OF BLAC MOTOR

Number of pole-pairs

3

Rated speed

Rated torque

Rated phase voltage (peak)

1000rpm

4.0Nm

158V

Rated phase current (peak)

4.0A

Phase resistance R,

6.0Q

Fig. 8(b).

V. CONCLUSIONS

Finite element analysis and measurements have shown that

the neglect of cross-coupling between the d- and q-axes of a

BLAC motor which results due to magnetic saturation, may

lead to significant errors in the rotor position estimation when

signal injection based sensorless control is employed. However,

by applying a simple error correction method, a significant

improvement in the accuracy of the rotor position estimation

can be achieved.

Fig. 7 compares the measured steady-state error in the

estimated rotor position for various d- and q-axis currents, ie

when the estimated rotor position is used for position

and

feedback. With conventional signal injection based sensorlessi

control, Fig. 7(a), the rotor position estimation error increases

with both the magnitude of iq and increasing positive values of

id, since the magnetic circuit then becomes more heavily

saturated and the influence of dq-axis cross-coupling becomes

more significant. For example, the error increases to 450 when

ird3A, iq=4A, while the root mean square (RMS) error in Fig.

7(a) is 21.1'. However, when the proposed error compensation

method is applied, the RMS rotor position estimation error is

reduced to only 3.20, Fig. 7(b).

jle,

REFERENCES

Ogasawara, and H. Akagi, "Implementation and position control

performance of a position-sensorless IPM motor drive system based on

magnetic saliency," IEEE Trans. Industry Applications, vol.34, no. 4, pp.

806-812, July-Aug. 1998.

M. J. Corley, and R. D. Lorenz, "Rotor position and velocity estimation

for

permanent

synchronous machine at standstill and

~~~~~~

~~~~~~~~~~~

LS~~~~

jII1dh~~~~~~~~~d

IEEE

Trans. magnet

~~higha salient-pole

speed,"

1998. Industry Applications, vol.34, no. 4, pp.

~~~~784-789,

July/August

[3 T. Aihara, A. Toba, T. Yanase, A. Mashimo, and K. Endo, "Sensorless

NO

torque control of salient-pole synchronous motor at zero-speed operation,"

.

g ^ .150

IEEE Trans. Power Electronics, vol. 14, no. 1, pp.202-208, Jan. 1999.

[4] J.I. Ha, K. Ide, T. Sawa, and S.K. Sul, "Sensorless rotor position

_[2]

A4-l l 01lilill 1ll 111 1 11 1

l > t II1! IIl

Es

[1] s.

il.-ited

a

curr-ent

0

3

(a) Conventional method

-Entlder

(e],ec, deg-,)

| ,.........................................................................................E

4o

i mw (S

estimation of an interior permanent-magnet motor from initial states",

IEEE Trans. Industry Applications, vol. 39, no. 3, pp.761-767, May-June

2003.

aa

1VF -[5]a H. Kim, K.K. Huh, and R.D. Lorenz, "A novel method for initial rotor

position estimation for IPM synchronous machine drives," IEEE Trans.

Industry Applications, vol. 40, no. 5, pp. 1369-1378, September/October

2004.

J.H.

Jang, S.K. Sul, J.I. Ha, K. Ide, and M. Sawamura, "Sensorless drive of

[6]

surface-mounted permanent-magnet motor by high-frequency signal

~~~~~~~~~~

~~~~~~~~~injection based on magnetic saliency," IEEE Trans. IndustryApplications,

vol. 39, no. 4, pp. 1031-1039, July-Aug. 2003.

P. Guglielmi, M. Pastorelli, A. Vagati, "Cross saturation effects in IPM

motors and related impact on zero-speed sensorless control," Conf Rec.

IEEE-IASAnnu. Mleeting, vol. 4, pp. 2546-2552, 2005.

[8] N. Bianchi, S. Bolognani, "Influence of rotor geometry of an interior PM

motor on sensorless control feasibility," Conf Rec. IEEE-IAS Annu.

Mleeting, vol. 4, pp. 2553-2560, 2005

[9] B. Stumberger, G. Stumberger, D. Dolinar, A. Hamler, M. Trlep,

-5

~~~~~~~~~~~~~[7]

permanent-magnet

synchronous

motor," IEEE

Trans.

Industry

Applications, vol. 39, no. 5, pp. 1264-1271, September/October 2003.

{A)

[10] A. E. Fitzgerald, Charles Kingsley, Jr., Stephen D. Umans, "Electric

Machinery, 5th Edition", McGraw-Hill Book, 1992.

1

4

(S)

(b) Proposed method

Fig. 8. Step speed response of signal injection based sensorless operation (speed

command: ±10 Hz, and ir~0).

0

Fig. 8 compares the estimated and actual rotor position when

the estimated rotor position is used for position feedback and

213