LEDALITE

Ledalite Document Package

Goldtech 1st Floor

Prepared By: John

Project Notes:

This looks cool.

Created with

LEDALITE

DocGenerator

www.ledalite.com

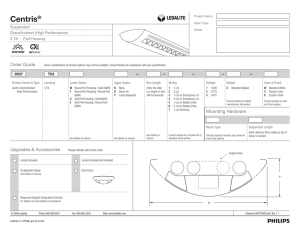

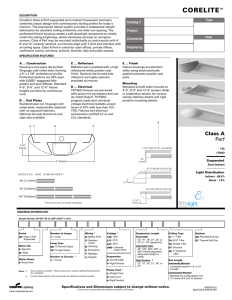

Centris

®

Suspended | Wall

Centris®

A clean, simple shape that’s incredibly affordable and

versatile. Centris offers designers a wide selection of

distributions, lamping and aesthetic options—all

available on our 9-day QuickShip program.

Suspended | Wall

QuickShip

| www.ledalite.com

Distributions for any space

1, 2, 3, 4

Wardrobe options

Price, delivery AND quality

Designed to address an array of lighting

applications, Centris offers suspended

and wall mounted lighting systems with

a full-range of distributions (direct/Indirect, semi-indirect and indirect).

Solve virtually any lighting challenge

using a diverse set of lumen packages

including up to four T8 or T5HO lamps.

Select from two distinct perforation

aesthetics: round perf housing

complements the fixture’s curved

form while the slot perf pattern adds

a sleek, contemporary look. Add

sculptured endcaps to complete

linear runs with tapered elegance.

How? Ledalite’s state-of-the-art,

fully-automated production line

ensures Centris products have a

consistent fit and finish and clean

hairline joints. It also delivers them

at a price and nine-day turnaround

time that’s tough for our competitors

to beat.

www.ledalite.com | Centris®

A clean, simple shape that’s incredibly affordable and

versatile. Centris offers designers a wide selection of

distributions, lamping and aesthetic options—all

available on our 9-day QuickShip program.

Suspended | Wall

QuickShip

| www.ledalite.com

Distributions for any space

1, 2, 3, 4

Wardrobe options

Price, delivery AND quality

Designed to address an array of lighting

applications, Centris offers suspended

and wall mounted lighting systems with

a full-range of distributions (direct/Indirect, semi-indirect and indirect).

Solve virtually any lighting challenge

using a diverse set of lumen packages

including up to four T8 or T5HO lamps.

Select from two distinct perforation

aesthetics: round perf housing

complements the fixture’s curved

form while the slot perf pattern adds

a sleek, contemporary look. Add

sculptured endcaps to complete

linear runs with tapered elegance.

How? Ledalite’s state-of-the-art,

fully-automated production line

ensures Centris products have a

consistent fit and finish and clean

hairline joints. It also delivers them

at a price and nine-day turnaround

time that’s tough for our competitors

to beat.

www.ledalite.com | Centris®

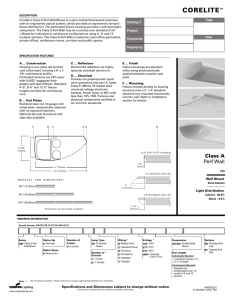

Suspended

3"

9"

Wall Mount

Indirect

Solid housing

Semi-Indirect

Round perf housing

Semi-Indirect

Slot perf housing

Direct/Indirect

Solid housing w/ solid baffle

Direct/Indirect

Round perf housing w/ solid baffle

Direct/Indirect

Round perf housing w/ round perf baffle

Direct/Indirect

Slot perf housing w/ solid baffle

3"

9-1/2"

Optional Sculptured Endcap

Indirect

Semi-Indirect

Direct/Indirect

Wall Indirect

Wall Semi-Indirect

Wall Direct/Indirect

Order Guide

Direct/Indirect

Solid housing w/ round perf baffle

Product Series/Type

Lamping

Lower Optics

Upper Optics

Run Length

Wiring

Voltage

Ballast

Finish

9502

9503

9504

9505

9506

9507

9508

H01

H02

H03

H04

T01

T02

T03

T04

Indirect

E Solid Housing

N None

D 50% Down Kit

Y 2 Down / 1 Up Kit

Enter total run

length in feet

1

2

3

5

7

1 120V

2 277V

3 347V

E Electronic

W Standard White

C Factory Color

X Custom Color

Centris Indirect (HP*)

Centris Indirect

Centris Semi-Indirect (HP*)

Centris Semi-Indirect

Centris Direct/Indirect

Centris Direct/Indirect (HP*)

Centris Wall Mount

*High Performance Optics

| www.ledalite.com

1 T5HO

2 T5HO

3 T5HO

4 T5HO

1 T8

2 T8

3 T8

4 T8

Semi-Indirect

L Round Perf Housing

I Slot Perf Housing

Direct/Indirect

C Solid Housing /

Solid Baffle

R Solid Housing /

Round Perf Baffle

M Round Perf Housing /

Solid Baffle

T Round Perf Housing /

Round Perf Baffle

U Slot Perf Housing /

Solid Baffle

Z Slot Perf Housing /

Round Perf Baffle

Total number must

be divisible by 4

1cct

2cct

1cct w/ Emergency cct

1cct w/ Battery Pack

1cct Dimming

Consult website for full list

of available wiring options

Consult website for full

list of supported ballasts

(also available with slot perf housing)

(also available with round or slot perf housing and solid baffle)

Wall Mount Semi-Indirect

Round perf gousing

Wall Mount Direct/Indirect

Solid housing w/ round perf baffle

Consult website for full list of

available factory colors

Direct/Indirect

Slot perf housing w/ round perf baffle

Wall Mount Indirect

Solid housing

www.ledalite.com | Centris®

Suspended

3"

9"

Wall Mount

Indirect

Solid housing

Semi-Indirect

Round perf housing

Semi-Indirect

Slot perf housing

Direct/Indirect

Solid housing w/ solid baffle

Direct/Indirect

Round perf housing w/ solid baffle

Direct/Indirect

Round perf housing w/ round perf baffle

Direct/Indirect

Slot perf housing w/ solid baffle

3"

9-1/2"

Optional Sculptured Endcap

Indirect

Semi-Indirect

Direct/Indirect

Wall Indirect

Wall Semi-Indirect

Wall Direct/Indirect

Order Guide

Direct/Indirect

Solid housing w/ round perf baffle

Product Series/Type

Lamping

Lower Optics

Upper Optics

Run Length

Wiring

Voltage

Ballast

Finish

9502

9503

9504

9505

9506

9507

9508

H01

H02

H03

H04

T01

T02

T03

T04

Indirect

E Solid Housing

N None

D 50% Down Kit

Y 2 Down / 1 Up Kit

Enter total run

length in feet

1

2

3

5

7

1 120V

2 277V

3 347V

E Electronic

W Standard White

C Factory Color

X Custom Color

Centris Indirect (HP*)

Centris Indirect

Centris Semi-Indirect (HP*)

Centris Semi-Indirect

Centris Direct/Indirect

Centris Direct/Indirect (HP*)

Centris Wall Mount

*High Performance Optics

| www.ledalite.com

1 T5HO

2 T5HO

3 T5HO

4 T5HO

1 T8

2 T8

3 T8

4 T8

Semi-Indirect

L Round Perf Housing

I Slot Perf Housing

Direct/Indirect

C Solid Housing /

Solid Baffle

R Solid Housing /

Round Perf Baffle

M Round Perf Housing /

Solid Baffle

T Round Perf Housing /

Round Perf Baffle

U Slot Perf Housing /

Solid Baffle

Z Slot Perf Housing /

Round Perf Baffle

Total number must

be divisible by 4

1cct

2cct

1cct w/ Emergency cct

1cct w/ Battery Pack

1cct Dimming

Consult website for full list

of available wiring options

Consult website for full

list of supported ballasts

(also available with slot perf housing)

(also available with round or slot perf housing and solid baffle)

Wall Mount Semi-Indirect

Round perf gousing

Wall Mount Direct/Indirect

Solid housing w/ round perf baffle

Consult website for full list of

available factory colors

Direct/Indirect

Slot perf housing w/ round perf baffle

Wall Mount Indirect

Solid housing

www.ledalite.com | | www.ledalite.com

www.ledalite.com | | www.ledalite.com

www.ledalite.com | 19750–92A Avenue

Langley, BC, Canada V1M 3B2

Tel: 604.888.6811

Toll free fax: 604.665.5352

Email: info@ledalite.com

www.ledalite.com

A Genlyte Company

Due to continuing product improvements, Ledalite reserves the right to change specifications without notice. © 2007 Ledalite. All rights reserved.

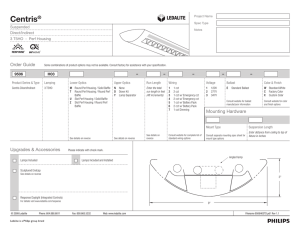

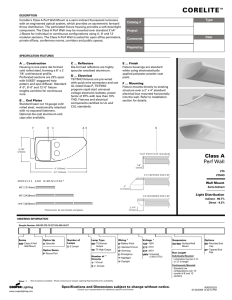

Centris®

Suspended

Project Name

GoldTech 1st Floor

Spec Type

A-1

Notes

Direct/Indirect

2 T8 - Perf Housing

Order Guide

Some combinations of product options may not be available. Consult factory for assistance with your specification.

9506

T02

U

N

–

–

–

–

–

Product Series & Type

Lamping

Lower Optics

Upper Optics

Run Length

Wiring

Voltage

Ballast

Color & Finish

Centris Direct/Indirect

2 T8

M Round Perf Housing / Solid Baffle

T Round Perf Housing / Round Perf

Baffle

U Slot Perf Housing / Solid Baffle

Z Slot Perf Housing / Round Perf

Baffle

N None

D Down Kit

Y Lamp Separator

Enter the total

run length in feet

(4ft increments)

1

2

3

4

5

6

7

1 120V

2 277V

3 347V

E Standard Ballast

W Standard White

C Factory Color

X Custom Color

Consult website for ballast

manufacturer information

Consult website for color

and finish options

1 cct

2 cct

1 cct w/ Emergency cct

2 cct w/ Emergency cct

1 cct w/ Battery Pack

2 cct w/ Battery Pack

1 cct Dimming

Mounting Hardware

Mount Type

See details on reverse

Upgrades & Accessories

See details on reverse

See details on

reverse

Consult website for complete list of

standard wiring options

Consult separate mounting spec sheet for

mount type options

Suspension Length

Enter distance from ceiling to top of

fixture in inches

Please indicate with check mark.

Lamps Included

Lamps Included and Installed

Sculptured Endcap

Dust Cover

See details on reverse

3"

Response Daylight (Integrated Controls)

For details visit www.ledalite.com/response

© 2007 Ledalite

Phone: 604.888.6811

9"

Fax: 800.665.5332

Web: www.ledalite.com

Email: info@ledalite.com

Filename 9506T02MN.pdf Rev 1

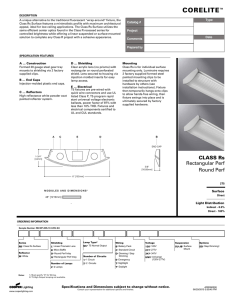

Centris®

Additional Information

Suspended

Direct/Indirect

Modules

2 T8 - Perf Housing

Module length excludes endcaps.

Nominal mount spacing for

individually mounted modules.

Photometry

Efficiency

Peak Candela Value

Peak to Zenith Ratio

Report #

Filename

84.1%

1029 @ 180°

1:1

Round Perf Housing

0

5

15

25

35

45

55

65

75

85

90

95

105

115

125

135

145

155

165

175

180

Horizontal Angle

22.5 45 67.5

90

Zonal

Lumens

678 678 678 678 678

673 668 662 649 654

622 595 572 542 543

535 486 457 414 412

431 374 334 312 319

312 268 251 246 253

193 178 180 161 165

92

110 108 100 105

45

53

70

88

99

15

29

52

63

71

5

23

42

56

59

45

111 171 181 226

203 305 448 516 560

378 437 594 679 716

541 571 692 793 830

692 702 780 850 880

818 820 855 898 919

918 913 933 942 953

986 980 987 992 998

1023 1022 1022 1019 1021

1029 1029 1029 1029 1029

180

80

90

70

50

30

10

0 RCR

1

2

3

4

5

6

7

8

9

10

85

77

70

64

59

54

50

46

42

39

37

85

74

64

57

50

45

40

36

33

30

27

85

70

59

51

44

38

33

30

26

24

21

85

68

55

46

39

33

29

25

22

20

17

30

75

69

62

57

52

48

44

41

38

35

33

75

66

57

51

45

40

36

32

29

27

24

75

63

53

46

40

34

30

27

24

21

19

Round Perf Baffle

Down Kit

Y

Lamp Separator

Specifications

0

45

90

0

50

50

30

58

51

44

39

35

31

28

25

23

21

19

58

49

42

36

31

27

24

21

19

17

16

Phone: 604.888.6811

Due to continuing product improvements, Ledalite reserves the right to change specifications without notice.

45

45

Based on a floor reflectance of 0.2

© 2007 Ledalite

Solid Baffle

90

Avg. Luminance (cd/m2)

70

Slot Perf Housing

1100 cd

172

432

557

613

602

538

430

278

98

70

50

Sculptured

Upper Optics

D

Coefficients of Utilization (%)

Ceiling:

Wall:

Flat (Standard)

135

135

63

161

210

218

203

156

106

75

51

3-1/2"

1/2"

Lower Optics

2101579

9506T02MN-TN.ies

Candela Distribution

0

Endcap

Mount Spacing

4' 0"

8' 0"

12' 0"

Optics MN Round Perf Housing / Solid Baffle

Report Summary

Vertical

Angle

Module

4ft

8ft

12ft

10

0

0

Vertical

Angle

58

47

39

33

28

24

21

19

16

15

13

21

17

15

13

11

10

8

8

7

6

6

55

65

75

85

Horizontal Angle

0

45

90

1371

887

709

701

936

671

563

617

772

569

661

644

IES files for this and other

photometric options can be

downloaded online at

www.ledalite.com

Fax: 800.665.5332

Web: www.ledalite.com

Housing

Die-formed 20 gauge cold-rolled steel.

Endcaps

Die-cast endcap or optional die-cast sculptured endcap.

Weight

3.0 lb/ft.

Joints

Self-aligning joining system with hands-free pre-joining wire access.

Optical System

Direct/Indirect: Constructed of 96% reflective white steel, and a

perforated optical filter with acrylic overlay to produce a direct/indirect

distribution. Baffles are white blades spaced 2-7/16" apart and are

3/4" deep (18 cells per 4ft section). Perforation of baffles and housing

is optional. Optional field installable Variable Optics kits provide the

ability to add additional downlight where needed.

Mounting

Aircraft cable gripper is tamper-resistant and provides infinite

vertical adjustment capability. Aircraft cable, crimp and cable gripper

independently tested to meet stringent safety requirements.

Semi-Indirect: Constructed of 96% reflective white steel to produce a

semi-indirect distribution.

Indirect: Constructed of 96% reflective white steel to produce an

indirect distribution.

High Performance options use additional highly-specular aluminum

reflectors.

Email: info@ledalite.com

Electrical

Factory pre-wired to section ends with quick-wire connectors.

Ballast

Electronic.

Approvals

Certified to UL and CSA standards.

Finish

High-quality powder coat. Available in Ledalite Standard White

(textured matte finish), and a selection of other factory and customerspecified colors. Consult factory for details.

Filename 9506T02MN.pdf Rev 1

Installation Documentation

ID-950

CENTRIS INDIRECT, SEMI-INDIRECT AND

DIRECT/INDIRECT SYSTEMS

Instructions included with this package:

Document

Description

950-ov01

950-en01

950-jt01

950-wall

30-rc6

General

Centris Installation Overview

Centris Mount @ End Installation

Centris Mount @ Joint Installation

Centris Wall Installation

Centris Row Configuration Layout

Luminaire Maintenance Procedures

PLEASE RETAIN PACKAGE FOR FUTURE REFERENCE

Ledalite Architectural Products

Phone: 604-888-6811 Toll Free Fax: 1-800-665-5332 www.ledalite.com

Rev. 0

950-ov01

CENTRIS INSTALLATION

Installation Instructions

1. Read All Installation Instructions Before Installing Fixtures.

2. Arrange boxed fixtures on floor in desired mounting locations.

Remove fixtures from boxes but keep the protective plastic on during installation.

3. General installation sequence:

A. Install ceiling mounting kits (see below).

B. & C. Install fixtures to mounting brackets at joints and ends. (see below).

! ATTENTION !

INSTALL IN ACCORDANCE TO NATIONAL

AND LOCAL ELECTRICAL CODES AND

BUILDING CODES.

NOTE

A. Ceiling Mounting Installation

See supplied installation instructions

CENTRIS 1LAMP T8 AND 3LAMP T8

CONFIGURATIONS REQUIRE CENTER LAMP

TO BE INSTALLED DIAGONALLY IN THE

MIDDLE OF A LAMP MODULE.

B. Centris Mount @ Joint: 950-jt01

See supplied installation instructions

MODULE LENGTH 4'-0"

C. Centris Mount @ End: 950-en01

See supplied installation instructions

MODULE LENGTH 8'-0"

Copyright 2007 Ledalite Architectural Products

Specifications and design subject to change without notice.

Phone: (604) 888-6811 Fax: (604) 888-2003 email: info@ledalite.com

Filename: 950_ov01 Rev.: A

950-en01

CENTRIS MOUNT @ END

Installation Instructions

1. Install ceiling components.

(See supplied mounting installation instructions.)

2. Install vertical aircraft cable pendant.

(See supplied mounting installation instructions.)

!

! ATTENTION

INSTALL IN ACCORDANCE TO NATIONAL

AND LOCAL ELECTRICAL CODES AND

BUILDING CODES.

3. Bend tab 90 or remove completely at mount location.

4. Attach mount bracket to each end of fixture using supplied screws. Screws will be tightened after leveling the fixture.

5. Hang fixture by inserting aircraft cable through aircraft cable adjuster in mount bracket at each end of fixture. Make fine

adjustments of height with supplied release key. Confirm fixtures are level end to end, then cut aircraft cable 1/4" below adjuster.

6. Level fixtures side to side by rotating mount bracket within slots. Tighten screws once mount bracket is in proper position.

7. For a power feed location, break required 1/2" knock-out(s) in reflector pan and insert supplied bushing(s). Use strain relief

under reflector to secure cable. Remove installed quick-wire plugs at power feed location and complete electrical connections

using wirenuts (supplied by others). Tuck wire connections into fixture wiring cavity.

8. Attach endcap with supplied hardware. Tighten endcap hardware until just snug.

ATTENTION: HAND TIGHTEN RECOMMENDED. USE LOW TORQUE SETTING ON POWER TOOLS.

9. To ensure all mounting system components have been installed correctly, temporarily apply a 25 lb. point load to each

mounting bracket location.

3 , 4

5 , 6

Adjust height with

release key

Mount bracket

Ref. No. 950BA01

Aircraft cable

Aircraft cable

adjuster

Level short edge

by rotating bracket

in fixture.

7

Power

cord

1/2" Bushing

Cut aircraft

cable 1/4"

below adjuster

Bend Tab

to 90 or break

off clean

8 STANDARD ENDCAP

7

Endcap

Endcap nut

(2 per end)

!

Wirenuts

(supplied by

others)

ATTENTION

HAND TIGHTEN

RECOMMENDED.

USE LOW TORQUE

SETTING ON

POWER TOOLS.

Wiring cavity

ATTENTION:

AIRCRAFT CABLE ADJUSTER

To ensure quick and easy installation

when using the aircraft adjusters follow

these simple steps:

1. Be sure to cut cable ends cleanly prior

to inserting into adjuster.

Recommended cutters for this task:

- H.K. Porter cable cutter cat. No. 0690TN

- Klein all purpose shears cat. No. 1104.

2. Carefully insert cable into tapered end.

3. DO NOT FORCE CABLE INTO ADJUSTER!

If cable does not insert easily or becomes

jammed during insertion, use the release

tool provided to remove cable, trim end

again and repeat process. DO NOT BEND

CABLE BELOW BOTTOM OF ADJUSTER.

4. Once cable is inserted in position, apply

a 25 lb point load to each mount bracket

to ensure all connections are secure.

8 SCULPTURED ENDCAP

Endcap

Copyright 2007 Ledalite Architectural Products

Specifications and design subject to change without notice.

Endcap screw

(2 per end)

!

ATTENTION

HAND TIGHTEN

RECOMMENDED.

USE LOW TORQUE

SETTING ON

POWER TOOLS.

Phone: (604) 888-6811 Fax: (604) 888-2003 email: info@ledalite.com

Filename: 950_en01 Rev.: A

950-jt01

CENTRIS MOUNT @ JOINT

Installation Instructions

1. Install ceiling components.

(See supplied mounting installation instructions.)

2. Install vertical aircraft cable pendant.

(See supplied mounting installation instructions.)

! ATTENTION !

INSTALL IN ACCORDANCE TO NATIONAL

AND LOCAL ELECTRICAL CODES AND

BUILDING CODES.

3. Insert joiners into crossplate on joining fixture and lock in place. Slide joiners into suspended fixture.

Check that joining fixture is held by the hooks on joiner ends.

4. Hang opposite fixture end by inserting aircraft cable through aircraft cable adjuster in mount bracket. After leveling the fixture

end, cut excess aircraft cable 1/4" below the adjuster.

5. For a non power location, plug together factory installed quick-wire plugs ensuring that all wiring connections are properly matched

and tucked into wiring cavity.

6. For a power feed location, break required 1/2" knock-out(s) in reflector pan and insert supplied bushing(s). Use strain relief under

reflector to secure cable. Remove installed quick-wire plugs at power feed location and complete electrical connections using

wirenuts (supplied by others). Ensure that all connections are properly matched and tucked into wiring cavity of the fixture.

7. Secure fixtures together using hardware supplied in joint kit. Ensure star washer faces the crossplate. Confirm fixtures are level;

if not, make fine adjustments as required using the release key. (See supplied Centris Mount @ End instructions for aircraft

cable adjuster details).

8. To ensure all mounting system components have been installed correctly, temporarily apply a 25 lb. point load to each

mounting bracket location.

3

3

TOP VIEW - Joining fixtures together

SUSPENDED

FIXTURE

NOTE:

ORIENTATION

OF JOINERS

JOINING FIXTURE

5

Aircraft cable

Power cord

6

7

Secure fixtures

together using

supplied hardware

Nuts (with

star washer)

Wirenuts

(supplied

by others)

Connection at non-power location

screws

Connection at power location

Copyright 2007 Ledalite Architectural Products

Specifications and design subject to change without notice.

Phone: (604) 888-6811 Fax: (604) 888-2003 email: info@ledalite.com

Filename: 950_jt01 Rev.: 0

LENGTH

16'

20'

8' - 1/8"

2

1

12' - 1/16"

24'

28'

32'

2

1

36'

40'

44'

2

1

48'

52'

56'

2

1

1

2

1

2

3

2

3

4

3

4

OVERALL*

16' - 1/4"

20' - 3/16"

24' - 1/8"

28' - 5/16"

32' - 1/4"

36' - 3/16"

40' - 3/8"

44' - 5/16"

48' - 1/4"

52' - 7/16"

56' - 3/8"

LENGTH

60'

64'

68'

72'

76'

80'

84'

88'

92'

96'

100'

2

1

2

1

2

1

8' - 1/8"

2

12' - 1/16"

5

4

5

6

5

6

7

6

7

8

7

OVERALL*

60' - 5/16"

64' - 1/2"

68' - 7/16"

72' - 3/8"

76' - 9/16"

80' - 1/2"

84' - 7/16"

88' - 5/8"

92' - 9/16"

96' - 1/2"

100'-11/16"

LUMINAIRE MAINTENANCE

GENERAL

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

SAVE THESE INSTRUCTIONS.

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed including the following:

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2. Do not let power supply cords touch hot surfaces.

3. Do not mount near gas or electric heaters.

4. Equipment should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

5. The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

6. Do not use this equipment for other than intended use.

Lamps

Fluorescent lamps typically have an average rated life of 20,000 hours (meaning some lamps will fail sooner, some later). Lamps are

driven in various combinations depending on ballast type, layout, etc. Under normal operating conditions it is recommended that a comprehensive maintenance plan be developed to achieve a complete lamp change out every 48 to 52 months. Some lamp failure will occur before this recommended interval and single lamp replacement should be considered where necessary.

Any required maintenance should be possible by one person depending on accessibility of fixtures. Lamps are removed by turning 1/4

turn (works for both bi-pin and butt-on sockets). Use care when removing or installing lamps and do not work above others.

Ballasts

Ballasts are generally very reliable and have a projected life of twenty years under normal operating conditions. If a situation arises where

two adjacent lamps are out, there could be a ballast problem and a replacement may be required. Lamp replacement should be tried first

in this instance and failing that, the appropriate ballast replaced.

Before attempting to verify and replace a ballast, it will be necessary to take the affected fixture module off line. To isolate power from the

unit, all circuits should be disconnected. Ballast locations can be found per the fixture's cross section view found in the project drawing set.

Ballasts are normally found below a reflector or pan and are secured to either the extrusion housing or the ballast pan itself. Reflectors

and pans are retained by sheet metal or machine screws. Once the retaining screws are removed, the reflector or pan is completely detached from the fixture exposing ballasts and wiring.

During the replacement process, special care should be taken to replace all fasteners and reconnect all applicable plugs.

Note that ballasts are warrantied by the ballast manufacturer and not by Ledalite. Ballast information is found on the ballast label. Contact

Ledalite for the ballast breakdown by project if required and for service line telephone numbers of ballast manufacturers.

Internal Components

Luminaires are certified by ETL to UL standards and CSA standards. When luminaires are operated as designed, all internal components

will be relatively inert to the effects of surface oxide accumulation which is the primary cause of scale and corrosion. The conditions of

certification preclude the operation of luminaires with missing, open or improperly installed lenses or covers.

Special Tools

Readily available tools such as bladed screwdrivers are required for maintenance and repair of system components. In some cases,

screws have a combination head for a bladed or No. 2 Robertson square drive bits. Aircraft cable cutting: recommended cutters, H.K.

Porter cable cutter catalogue No. 0690TN, or Klein all purpose shears catalogue No. 1104.

Outside Painted Surfaces

The outside surfaces of all components are finished with high quality powder paint. This finish is specially formulated to provide a durable

scratch resistant coating. It is recommended that all component surfaces be cleaned on a regular schedule to remove accumulated dust

and dirt. Care should be taken to use only non-abrasive substances; i.e. clean cloths and household solutions such as a non-streaking

bathroom tub and tile cleaner. Best results are obtained by wetting a cotton cloth and wiping clean. Do not spray solutions directly onto

the fixture: residue can accumulate on optics which can be difficult to remove

Internal Reflector Systems

Lighting performance is affected significantly by the reflectivity of the optical system and it is recommended that all fixture reflectors be

dusted periodically, possibly during a systematic lamp changing operation. Any cleaning of reflectors should be carried out with care as the

materials used to optimize performance are at the same time vulnerable to marring. It is recommended that a hand held vacuum cleaner

with a soft brush head be used for this operation. Grease can be removed using common household glass cleaner, and a soft cloth.

Plastic Surfaces

Plastic materials which form part of the exterior of the fixtures, such as lenses, are more susceptible to scratching and marring than the

painted finish. Special attention should be paid to the cleanliness of the materials using mild soap and water only.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

SAVE THESE INSTRUCTIONS.

Copyright 2007 Ledalite Architectural Products

Note: Specifications and designs subject to change without notice.

Phone: 604-888-6811

Fax: 604-888-2003

Filename: 30a_ov01.pub

www.ledalite.com

Rev:

C