Appendix F Itemized Measures Descriptions And Rates

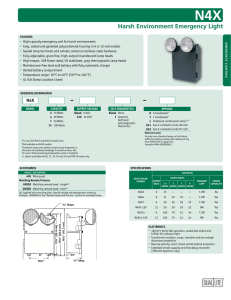

advertisement

Appendix F Itemized Measures Descriptions and Rates Itemized Measure Descriptions L – Lighting Measures L-A. Screw-in Compact Fluorescent Lamps (CFLs) Must replace incandescent lamps. No Itemized Incentive will be paid for fixtures that have previously received a rebate in this category (exceptions may apply). Replacement CFLs may be self-ballasted, modular (lamp with ballast adapter), or cord and plug retrofit kits. All self-ballasted lamps must have electronic ballasts and be ENERGY STAR ®-qualified. Modular units>=15 Watts must have electronic ballasts. For all units, lamp/ballast efficacy must meet these requirements: Lamp Power & Configuration Minimum Efficacy (Lumens Per Watt, Based on Initial Lumen Data) Bare Lamp: Covered Lamp (no reflector): Lamp Power < 15 Lamp Power >= 15 Lamp Power < 15 Lamp Power = 15 and < 19 Lamp Power = 19 and < 25 Lamp Power = 25 Covered Lamp Lamp Power < 20 (with reflector): Lamp Power = 20 45.0 60.0 40.0 48.0 50.0 50.0 33.0 40.0 In addition, when replacing the following wattages of incandescent lamps, all replacement Bare Lamp CFLs must have the following Minimum Lumen Output (shown on the manufacturer's specification sheet): Wattage of A-Shaped Incandescent Bulb CFL Minimum Lumen Output (based on 100 hr. initial values) 40 60 75 100 150 Minimum of 450 Minimum of 800 Minimum of 1,100 Minimum of 1,600 Minimum of 2,600 L-B. Compact or Linear Fluorescent Fixtures Only complete new fixtures or modular retrofits with hardwired ballasts qualify. Must replace an incandescent or mercury vapor fixture. All ballasts must be electronic. CFLs/ballasts must meet the same efficacy requirements as in category A. CFL ballasts must be Programmed Start/Programmed Rapid-Start with PF >=0.90 and THD <=20%. Linear fluorescent lamps/ballasts must meet the specifications defined in categories D below. Fixtures in this category are not eligible for additional Itemized Incentives under categories A, D, or G. L-C. Induction Lamps and Fixtures Only complete new induction fixtures >=55 Watts that replace existing incandescent or mercury vapor fixtures qualify. Induction lamps <55 Watts are considered CFLs and may qualify under category A. Each new fixture must have a mean lamp/ballast efficacy >50 LPW. Indoor, outdoor area, and parking lot lighting qualify, but roadway and street lighting do not. L-D. T8 or T5 Linear Fluorescent Lamps with Electronic Ballasts Itemized Incentive applies to existing T12 lamps and magnetic ballasts that are replaced by T8 or T5 lamps with the electronic, high frequency (>=20 kHz), UL-listed ballasts that are: warranted against mechanical or electrical defects for five years, and have PF >=0.90. At full light output, ballast for 4-foot and 8-foot lamps must have THD <= 20%, while ballast for 2-foot and 3-foot lamps must have THD <=32%. For T8 lamp installations, Instant Start and Programmed Start/Programmed Rapid-start ballasts, described below, all qualify. Programmed Start/Programmed Rapid-Start ballasts must be used for T5 lamp installations. The manufacturer’s specification sheet must document the characteristics listed below for each ballast type. Instant Start Ballasts - When T8 lamps are being installed for general illumination purposes, Instant Start ballasts must be used. Programmed Start/Programmed Rapid-Start Ballasts - When occupancy sensors are installed to control circuits in lamp/ballast retrofits, Programmed Start/Programmed Rapid-Start ballasts are required in order to maximize lamp life. Category I Occupancy Sensor Itemized Incentives may also apply. 12/28/2004 F-1 Version 1.0 T8 lamps >= 30 watts, must meet the 2nd or 3rd generation and < 30 watts must meet 4th generation requirements (see Section 1.4). Replacement lamps earning Itemized Incentives in this category are not eligible for rebates under categories B, D, or G. A delamping Itemized Incentive may also apply. Delamping is the permanent removal of existing T12 lamps/ballasts and unused lampholders from existing fixtures without replacing the lamps. To receive credit for delamping, customers must not remove more than half of the existing lamps/ballasts (along with lampholders) from each fixture. The total number of lamps claimed for delamping may not be more than the number of replacement T8 or T5 lamps installed. Customers are responsible for deciding whether delamping will maintain adequate light levels. L-E. High-Intensity Discharge (HID) Fixtures, Pulse Start Only complete new HID (metal halide or high-pressure sodium) fixtures that replace, one for one, existing incandescent or mercury vapor fixtures qualify. The HID system must have a mean lamp/ballast efficacy of 45 LPW for compact sources (<=100 Watts), and 55 LPW for standard or full-size sources (>100 Watts). Metal halide fixtures under 400 Watts can use either electronic or electromagnetic ballasts. Roadway and street lighting do not qualify. L-F. Ceramic Metal Halide (CMH) Fixtures Only complete new CMH fixtures that replace, one for one, existing incandescent, halogen, or halogen infrared fixtures qualify. CMH lamps must be <75 Watts with mean lamp/ballast efficacy >55 LPW. L-G. Interior High Bay Linear Fluorescent Four Lamp T5 or Six Lamp T8, T5 Fixtures Only complete new 4-lamp T5 or 6-lamp T8 or T5 fixtures qualify. Must use T8 or T5 lamps and ballasts as specified in categories B, & D. New fixture must replace, one for one, existing incandescent, T12 high output fluorescent or High Intensity Discharge (HID) fixtures >=400 Watts in interior high bay installations. T8 lamps >= 30 watts, must meet the 2nd or 3rd generation requirements (see Section 1.4). T8 lamps < 30 watts must be submitted using the calculated approach (not eligible for this itemized measure) and must meet 4th generation requirements. New fixture count cannot exceed number of fixtures removed. All fixtures must have a reflector with a minimum of 90% reflectivity. Exterior installations (roadway, street lighting, outdoor area, and parking lot lighting) do not qualify. Fixtures in this category are not eligible for additional Itemized Incentives under categories B, & D. L-H. Interior Metal Halide Pulse Start Fixtures Only Pulse Start metal halide lamps/ballasts <=350 Watts that replace existing standard metal halide lamps/ballasts >=400 Watts qualify. Both retrofit kits and new fixtures qualify. L-I. Occupancy Sensors This Itemized Incentive applies to passive infrared and/or ultrasonic detectors only. Wallbox and wall-or ceiling-mounted lighting sensors must be hardwired and control interior fixtures. Self-contained wallbox lighting sensors (defined as units without an exterior switchpack or relay that are designed to replace a standard wall switch) must not control more than 500 Watts. Wallor ceiling-mounted sensors must not control more than 1,000 Watts. High bay lighting sensors must control interior high bay fluorescent fixtures as described in category G. L-J. Photocells Itemized incentive applies to built-in or stand-alone photoelectric cells that switch outdoor lighting loads on at dusk and off at dawn. L-K. Time Clocks Must control lighting equipment. All units must feature a minimum 3-hour battery back-up to avoid time loss during power outages. For outdoor lighting without a photocell, astronomical time clocks (where on-off time follows sunset and sunrise) are required. L-L. LED Exit Signs Only new exit signs that replace incandescent exit signs qualify. Non-electrified (such as tritium) and remote exit signs are not eligible. All new exit signs must meet UL-924 requirements. Exit signs must have a usage level <=5 Watts and a minimum product life of 10 years or be listed as ENERGY STAR®-Qualified. Manufacturer’s information stating the model number and ENERGY STAR® qualification or other qualifying specification sheet must be submitted with each Itemized Incentive form. New exit signs must meet local fire codes. Retrofit kits are not eligible. 12/28/2004 F-2 Version 1.0 L-M. Channel Signs (LED) Must replace incandescent-lighted or neon-lighted channel letter signs. Only red LED retrofit kits or complete replacement signs using red LEDs are eligible. Replacement signs cannot use more than 20%of the actual input power of the sign that is replaced. Measure the length of the sign as follows: 1. Measure the length of each individual letter at the centerline. Do not measure the distance between letters. 2. Add up the measurements of each individual letter to get the length of the entire sign being replaced. BF =Ballast Factor CFL =Compact Fluorescent Lamp CRI =Color Rendering HID =High Intensity Discharge LED=Light Emitting Diodes LPW=Lumens Per Watt Abbreviations PF =Power Factor THD =Total Harmonic Index Distortion UL =Underwriters Laboratory < Less than > Greater than <= Less than or Equal to >= Greater than or Equal to H- Other HVAC Measures Attach a manufacturer’s technical specifications (e.g. cut sheet) documenting size and efficiency of HVAC units. H-A. Package Terminal Air Conditioners or Package Heat Pumps Package terminal air conditioners (PTAC) and Package terminal heat pumps (PTHP) are through-the-wall, self-contained units and are 2 tons (24,000 Btu/hr) or less. Only those units that have an EER that is 20% higher than the minimum are eligible. Minimum EER is calculated from the following equation: Min EER = 10.0 - (0.16 x _____________ ÷ 1,000) (capacity in Btu/hr*) *If the capacity is less than 7,000 Btu/hr, use 7,000. If the capacity is greater than 15,000 Btu/hr, use 15,000. H-B. Setback Programmable Thermostats Must automatically adjust the temperature setting of your heating and air conditioning system at pre-selected times to make sure energy is consumed only when needed. Must have automatic setback feature. The system “fan” switch must have an “on” feature that circulates air continuously. This measure is not eligible for additional Itemized Incentives under category M in the Gas Measure definitions. H-C. Reflective Window Film Film must have a minimum five-year manufacturer’s warranty. Itemized incentives are not available for windows with northern exposure. Space must be cooled by vapor-compression air conditioner (evaporatively-cooled space not eligible). Film must have either a solar heat gain coefficient (SHGC) <= 0.39 and be applied to clear, single-pane glass, or film can have an SHGC <=0.47 and visible transmittance/solar heat gain coefficient (VT/SHGC) ratio > 1.3. Specification must be documented on the invoice, as well as square footage installed. To convert Shading Coefficient (SC) to SHGC use the following equation: SHGC = SC x .87. H-D. Advanced Evaporative Coolers Must replace an existing, vapor-compression air conditioning system, or the existing compressor must be made inoperative. Must not have “constant bleed” option. No Itemized Incentive is available for CEC climate zones 1 and 3. Tonnage on Itemized Incentive form is based on the capacity of the package unit that is being replaced. For evaporative coolers, one equivalent ton of cooling is defined as 1300 cfm of 0.1” static pressure. The invoice should contain information describing what is being replaced. An advanced evaporative cooler (AEC) must have a rigid, manufactured evaporative media with a rated saturation effectiveness of 0.85 or better (a natural fiber pad is not allowed – the rigid media is generally 12” thick), and be equipped with water quality management system that provides positive removal of sump water on a regular interval (a bleed system is not allowed). H-E. Variable Frequency Drives (VFDs) VFD incentives are for fan applications on HVAC systems. The maximum fan size is 100 hp. The installation of a VFD on a HVAC fan is eligible for an Itemized Incentive only if throttling devices, such as inlet vanes, bypass dampers and throttling valves, are removed or permanently disabled. A 3% impedance choke is recommended. 12/28/2004 F-3 Version 1.0 Abbreviations EER= Energy Efficiency Ratio SHGC =Solar Heat Gain Coefficient CEC =California Energy Commission VT =Visible Transmittance Definitions British Thermal Unit (Btu): The amount of heat required to raise the temperature of one pound of water by one degree Fahrenheit. Energy Efficiency Ratio (EER): The cooling capacity of an air-conditioning unit (Btu/hr) divided by the electric power consumption (watts). Tons: A measure of heat removed over a period of time by an air-conditioning or refrigeration system (1 ton =12,000 Btu/hr). How to Calculate Tonnage Take the capacity in Btu/hr at ARI test conditions. Divide by 12,000 Btu/ton and round to the nearest tenth. If Btu/hr and ton rating are not equivalent in product literature, Itemized Incentive must be calculated using manufacturer’s Btu/hr rating. New efficiency rating must be based on ARI test conditions. F – Food Service Measures F-A. Connectionless Steamers Must replace existing electric steamer. Connectionless electric steamers with full load efficiency of 50 percent or greater qualify. Full load efficiency (potato cooking test) must be in accordance with the American Society for Testing and Materials (ASTM) Standard F1484. Consult with manufacturer or manufacturer’s representative to determine if a specific connectionless model qualifies. F-B. Insulated Hot Food Holding Cabinets Must replace existing electric hot food holding cabinet. This measure does not include cook and hold equipment. Measures B1, B3 and B5 include electric hot food holding cabinets that are fully insulated and have solid doors, in full, three-quarters and half sizes respectively. A higher rebate level is offered for measures B2, B4 and B6 which must operate with an energy rate of: B2 Less than or equal to 0.5 kW for full size cabinets B4 Less than or equal to 0.4 kW for three-quarter size cabinets B6 Less than or equal to 0.3 kW for half size cabinets All operating energy rates must be in accordance with the American Society for Testing and Materials (ASTM) Standard F2140. Consult with the manufacturer or manufacturer’s representative to determine if a specific insulated hot food holding cabinet model qualifies for the higher rebate level. OT – Other Technology Measures OT-A. Sprinkler to Drip Irrigation Must convert from a high-pressure, impact-type, sprinkler irrigation system (50 psi operating pressure or more at the sprinkler head) to a micro-irrigation system. Not applicable to new plantings of vineyards or orchards unless a vineyard or orchard was the previous crop on the field. Drip tape systems are not eligible. Include an Assessor’s Parcel Map or other documentation to verify acreage. OT-B. Low Pressure Sprinkler Nozzles Must convert from a high-pressure, sprinkler system nozzle (50 psi operating pressure or more at the sprinkler head.). Must be accompanied by a pumping plant analysis to ensure reasonable pumping efficiency (45% Overall Pumping Efficiency or above) after the conversion. Portable hand move or solid set systems may apply. R – Refrigeration Measures Itemized incentives are for replacing or retrofitting existing medium and low temperature refrigeration equipment. Medium temperature refers to refrigerated space temperatures between 1°F and 35°F. Low temperature covers temperatures below 0°F. High temperature is defined as operations involving an evaporator temperature of 45°F and higher. Projects that involve air conditioning or other high temperature refrigeration applications are not eligible. 12/28/2004 F-4 Version 1.0 Energy Efficiency Ratios (EERs) are calculated as the load transported by a device (BTU/hr) per Watt of electrical energy required by that device at design loads and temperatures per the manufacturer cut sheets. TD – Temperature Difference is the difference between design wet bulb and design dry bulb temperatures. All areas are measured in square feet; lengths and perimeters are measured in feet. TVX – Thermostatic Expansion Valve controlled by temperature to optimize the thermal cycle of refrigeration. EPR – Evaporator Pressure Regulator ECM Electronically Commutated Motors R-A. Night Covers for Display Cases Must install a cover on an otherwise open display case to decrease cooling load of the refrigerated cases during off hours. It is recommended that these film type covers have small perforated holes to decrease moisture buildup. The cover must be applied for a period of at least six hours. Customer should consider using proper compressor capacity modulation mechanisms (such as VSD or cylinder un-loader). * † Ø R-B. Strip Curtains for Walk-in Boxes Must install new strip curtains or clear plastic swinging doors on doorways of walk-in boxes and refrigerated warehouses. This Itemized Incentive is not available for replacement of existing strip curtains that have useful life left. Itemized incentive is based on the square footage of the doorway. R-C. & D. Glass Doors on Open Display Cases Must install glass doors on an existing open multi-deck display case (low or medium temperature). This measure can be applied to self-contained (with its own condensing unit) as well as remote fixtures. Itemized incentive is based on number of doors installed. R-E. & F. New Refrigeration Display Case with Doors Must replace an existing open multi-deck display case with a new high efficiency reach-in unit with standard glass doors with ECM fan, T-8 lamps and electronic ballast. This measure can be applied to self-contained or remote cases. New case length must be equal to or shorter than original case. R-G. New High Efficiency Refrigeration Display Case with Special Doors (Low Temp) A new high efficiency reach-in display case must replace an existing low temperature self-contained or remote reach-in as follows: Existing T-12 lamps, magnetic ballast shaded pole fan motor standard glass doors Replacement T-8 lamps, electronic ballast ECM fan motor(s low/no anti-sweat glass double pane doors meeting the requirements of measure H This measure cannot be used in conjunction with Anti-Sweat Heat Controls (I).* R-H. Special Doors with Low/No Anti-Sweat Heat on Low Temperature Display Cases Must replace an existing standard glass door of a low temperature reach-in display case with a special glass door that requires minimum to no anti-sweat heat (ASH). Doors must prevent condensation from occurring within the frame assembly. Total door rail, glass, and frame heater amperage (at 120 volts) cannot exceed 0.39 amps per foot. Itemized incentive is based on number of doors replaced. This measure cannot be used in conjunction with Anti-Sweat Heat Controls (I). R-I. Anti-Sweat Heat (ASH) Controls Must install a device that senses the relative humidity in the air outside of the display case and reduces or turns off the glass door (if applicable) and frame anti-sweat heaters at low humidity conditions. Equivalent technologies that can reduce or turn off antisweat heater based on the amount of condensation formed on the inner glass pane may also qualify. This measure cannot be used in conjunction with measures involving special glass doors with low/no Anti-Sweat Heat (G & H). Itemized Incentive is based on the total linear footage of the case. R-J. Insulation for Bare Suction Lines Must insulate bare refrigeration suction lines of 1 5/8 inches or less on EXISTING equipment only. Medium temperature lines require 3/4-inchof flexible closed-cell nitrite rubber, or equivalent insulation, and low temperature lines must have 1-inch of the 12/28/2004 F-5 Version 1.0 same insulation. Insulation exposed to outside weather must be jacketed (such as with a medium-gauge aluminum jacket) or protected from the weather in some way. Itemized incentive is based on the length, in linear footage, of the insulation installed. R-K. Door Gaskets on Solid Doors Must replace a worn gasket on the insulated opaque door of a walk-in or reach-in cooler or freezer. Replacement gaskets must meet the manufacturer’s installation specifications, specifically regarding dimensions, materials, attachment method, style, compression, and magnetism. Itemized incentive is based on total door perimeter in linear feet. R-L. Door Gaskets on Glass Doors Must replace a worn gasket on a reach-in glass door of a cooler or freezer. Replacement gaskets must meet the manufacturer’s installation specifications, specifically regarding dimensions, materials, attachment method, style, compression, and magnetism. Itemized incentive is based on total door perimeters in linear feet. R-M. & N. Auto-Closers for Main Cooler or Freezer Doors The auto-closer should be applied to the main insulated opaque door of a walk-in cooler or freezer. The auto-closer must be able to firmly close that door when it is within one inch of full closure. R-O. Evaporator Fan Controller for Walk-in Coolers Must reduce air flow of evaporator fans in medium-temperature walk-in coolers when compressor(s) cycle off and there is no refrigerant flow through the evaporator. Must control a minimum fan load of 1/20 horsepower where the fan(s) operate continuously at full speed. Must reduce fan motor power by at least 75% during the compressor off-cycle. Do not use if any of the following conditions apply: 1) the compressor runs all the time with high duty cycle; 2) the evaporator fan does not run at full speed all the time; 3) the evaporator fan motor runs on poly-phase power; 4) the evaporator fan motor is not shaded-pole; or 5) evaporator does not use off-cycle or time-off defrost. R-P. Air-Cooled Condenser to Evaporative Condenser Must replace an existing air-cooled condenser with an evaporative condenser in climate zones 9, 10, 11, 12, 13, 14, and 15 only. Retrofit is permitted for both conventional multiplex and single compressor systems. New evaporative condenser should be sized at 18°F TD. . R-Q. Energy Efficient Condenser Must replace existing condenser with an energy efficient unit equipped with several additional control mechanisms. This measure is only applicable to existing multiplex systems and does not apply to those converted from single compressor to multiplex; otherwise, see measure R. Retrofit systems should operate at: Air-Cooled -- 8°F TD for low temperature and 13°F TD for medium temperature systems with EER of 105 Btu/hr/Watt (for the condenser only); or Evaporatively Cooled -- 18°F TD above ambient wet-bulb temperature with EER of 240 Btu/hr/Watt (for the condenser only). EER is determined by the total heat rejection for the condenser at the specified temperature divided by the total electric load of all condenser related fans and pumps added to the system. Retrofit must include Variable Speed Drive (VSD) for the condenser fan motors and variable set point floating head pressure controls. R-R. High Efficiency Multiplex Compressor System Replace inefficient single compressor per line-up system with a high efficiency, multiplex (parallel) system. High efficiency features of this measure must include floating head pressure by means of a variable speed fan control. In a multiplex system, multiple compressors serve a specific suction group, and each suction group serves one or more lines-ups having similar temperatures. For combining high efficiency multiplex compressor system with energy efficient condenser, see measure S. R-S. High Efficiency Multiplex Compressor System with Efficient Condenser Replace inefficient single compressor per line-up system with a high efficiency multiplex system and efficient condenser meeting the standards of measures Q and R. 12/28/2004 F-6 Version 1.0 R-T. Vending Machine Controller Intended for refrigerated vending machines containing only non-perishable bottled and canned beverages. Controller must include a passive infrared occupancy sensor to turn off fluorescent lights and compressor when surrounding area is unoccupied for 15 minutes or longer. Control logic should periodically power up machine at two hour intervals to maintain product temperature and provide compressor protection. Refurbished vending machines that include this option are eligible. R-U. & V. Efficient Evaporator Fan Motor Applicable to existing standard efficiency shaded pole evaporator fan motor of refrigerated display cases or fan coil systems in walk-ins. Shaded pole motors to be replaced by either electronically commutated motors (ECM) or permanent-splitcapacitor (PSC) motors. Notes * Itemized incentive is based on linear footage (length in feet) of the case. † Customer should consider using EPR and possibly resetting to higher suction temperatures when shields are applied. Customer should consider resizing TVX and resetting suction pressure to a higher value. Ø Case manufacturer must not have objections to the use of this measure. G – Natural Gas Measures Technical Requirements: Itemized incentives are available only for the replacement of older, inefficient gas equipment. If you are uncertain whether equipment qualifies, contact a utility representative. California Energy commission CEC and/or Gas Appliance Manufacturers Association GAMA equipment efficiency listed ratings prevail over all submitted technical documentation, unless otherwise approved. If the size and efficiency are not shown on the invoice, you must include a manufacturer’s specification sheet documenting these characteristics. Properties such as homes, condominiums, apartments or any other residential dwellings do not qualify. G-A. Commercial Clothes Washer Commercial clothes washers must be specified as category Tier 1, Tier 2, Tier 3a, or Tier 3b by Consortium for Energy Efficiency (CEE). Specifically, the qualified equipment’s Modified Energy Factor (MEF) must be greater than or equal to 1.42 and its water factor (WF) must be less than or equal to 9.5. A list of CEE-qualified commercial clothes washers can be found on CEE’s web site http://www.CEE1.org/com/cwsh/cwshspec.pdf. The invoice should clearly identify the brand and model of washer. A manufacturer’s specification sheet is also required. The qualified commercial clothes washer must be used in conjunction with gas water heating or gas drying. Therm savings result from the use of less hot water than conventional clothes washer designs. G-B. Storage Water Heater Water heaters must meet efficiency requirements based on size, as shown in Table 1. If the size and efficiency are not shown on the invoice, you must include a manufacturer’s specification sheet documenting these characteristics. Table 1. Storage Water Heater Input Rating Volume (gal) <= 75,000 Btuh >= 30 >= 40 >= 50 > 75,000 Btuh Required Efficiency Energy Factor >= 0.61 Energy Factor >= 0.60 Energy Factor >= 0.58 Thermal Efficiency = 82% All required efficiencies exceed Title 20 & 24 standards, as prescribed above. 12/28/2004 F-7 Version 1.0 G-C. Space Heating Boiler Boilers must meet efficiency requirements based on size and type, as shown in Table 2. Include a manufacturer’s specification sheet documenting these characteristics. Boiler must be used for space heating for human comfort as defined by California Titles 20 & 24 standards. Boilers larger than or equal to 2,500 MBtuh must use the calculated approach to estimate energy savings (refer to Section 2.3.24 Gas Boiler Measures). Table 2. Space Heating Boiler Type Input Rating Steam < 300 MBtuh Small water < 300 MBtuh Large >=300 MBtuh – < 2,500 MBtuh Required Efficiency AFUE >= 77% AFUE >= 82% Thermal Efficiency >= 84% All required efficiencies exceed Title 20 & 24 standards, as prescribed above. G-D. Commercial Boiler (Non Space Conditioning/ Non-Process Related) Available to commercial end-use customers (NAICS codes 111, 112, 42, 44, 45, 48-49, 51-56, 61-62, 71-72, 81 & 92). Only boilers > 75,000 Btuh qualify. Must meet a minimum thermal efficiency of 84%. Include a manufacturer’s specification sheet documenting these characteristics. Boiler must not be used for space conditioning. Boiler must not be used for industrial (process) end-use. Boilers larger than or equal to 2,500 MBtuh must use the calculated approach to estimate energy savings (refer to Section 2.3.24 Gas Boiler Measures). G-E. Instantaneous Water Heater (Non-Process Related) Available to commercial end-use customers only (NAICS codes 111, 112, 42, 44, 45 ,48-49, 51-56, 61-62, 71-72, 81 & 92). Water heaters must meet efficiency requirements based on size, as shown in Table 3. Only instantaneous water heaters (as defined by the California Energy Commission Title 20 & 24 standards) used for non-process hot water applications qualify. The manufacturer name and equipment model number must be provided. Customers must provide proof of the tankless nature of the water heater (e.g., manufacturer equipment specification sheets). Table 3. Instantaneous Water Heater (Non-Process Related) Input Rating Required Efficiency <= 200 MBtuh Energy Factor >= 0.63 > 200 MBtuh Thermal Efficiency >= 82% All required efficiencies exceed Title 20 & 24 standards, as prescribed above. G-F. Process Boiler Available to industrial end-use customers who manufacture a sellable product only (NAICS codes 31-33). Manufacturing involves the mechanical or chemical transformation of materials or substances into a new product which is neither a structure nor any other fixed improvement. Boilers must meet a minimum combustion efficiency of 82% as installed. Only process boilers (i.e., units not primarily used for domestic hot water, space conditioning, pool or spa use) qualify. The manufacturer name and equipment model number must be provided. A flue gas analysis, measured under full load conditions, is required to document combustion efficiency after installation is complete. Boilers larger than or equal to 2,500 MBtuh must use the calculated approach to estimate energy savings (refer to Section 2.3.24 Gas Boiler Measures). G-G. Commercial Pool Heater Available for swimming pool heating and must replace pre-existing pool heater. The commercial pool and spa heater must be certified to meet the following requirements: 1) heater must be equal to or greater than 84% thermal efficiency 2) must have an “on/off” switch and have no pilot light and (3) size of equipment must be between 500 Mbtu and 2000 Mbtu. 12/28/2004 F-8 Version 1.0 G-H. Direct Contact Water Heater Only direct contact water heaters for process end-uses qualify (NAICS codes 31-33). In direct contact water heater systems design, heat from a flame comes into direct contact with small droplets of cold water which run through a stainless steel heat exchange media. Droplets composed from the process come into direct contact with rising heat from the flame and the water is heated directly. Boilers must meet efficiency requirements based on size as shown in Table 4. Table 4. Direct Contact Water Heater Input Rating Required Efficiency <= 300,000 Btuh AFUE >= 88% > 300,000 Btuh Thermal Efficiency > 90% All required efficiencies exceed Title 20 & 24 standards, as prescribed above. G-I. Pipe Insulation Insulation must be added to existing nonresidential bare pipe systems which transfer fluid directly from gas-fired equipment. Insulation must be a minimum of two inches (2”) of fiberglass or foam. Minimum qualifying pipe diameter is one inch (1”). The manufacturer name and insulation material/R-value are required. G-J. Tank Insulation Insulation must be added to existing nonresidential bare storage or solution tanks which are coupled to gas-fired equipment by pipes. Insulation must be a minimum of two inches (2”) of fiberglass or foam. The manufacturer name and insulation material/R-value are required. G-K. Greenhouse Heat Curtain Only installation of interior curtains for heat retention in existing gas-heated greenhouses qualify. The Itemized Incentive applies to new and retrofit curtain system installations in existing greenhouses for specific agricultural end-use. The agricultural uses include horticultural specialties such as ornamental floriculture, nursery products and food crops grown under cover (NAICS 1114) and landscape and horticultural services (NAICS 541 & 561) which store agricultural products under cover. Include a manufacturer’s specification sheet documenting type of curtain. G-L. Infrared Film for Greenhouses Installations of single sheet infrared anti-condensate polyethylene plastic with a minimum 6 mil. thickness for heat retention on existing heated greenhouses will qualify. Greenhouses must be for agriculture and floriculture uses (NAICS 1114), as well as landscape and horticultural services (NAICS 541 & 561). A manufacturer’s specification sheet must be included. G-M. Setback Programmable Thermostats Must automatically adjust the temperature setting of the heating or air conditioning system at pre-selected times to make sure energy is consumed only when needed. Must have automatic setback feature. The system “fan” switch must have an “on” feature that circulates air continuously. This measure is not eligible for additional Itemized Incentives under Category B in the Other HVAC Measure definitions. G-N. Low-Flow Pre Rinse Spray Valves Low flow pre-rinse valves include a spray nozzle, a squeeze lever, and a dish guard bumper and also typically include a spray handle clip that will lock the handle in the spray position. The low flow pre-rinse valve must be designed and marketed specifically for use in commercial food service applications and must replace a pre-rinse valve with a nominal flow rate of at least 2.6 gpm. The maximum flow rate of the low flow pre-rinse valve must be less then 1.6 gpm at a flowing water pressure of 60 psi. No dual flow spray valves will be allowed to qualify for the Itemized Incentive since there is no control as to how these valves would be operated after installation (high or low flow). 12/28/2004 F-9 Version 1.0 Itemized Measure Rates Measures Incentive Rate Lighting Itemized Measures L-A. Screw-in Compact Fluorescent Lamps 5–13 watts 14–26 watts 14–26 watts, Reflector > 27 watts L-B. Compact and Linear Fluorescent Fixtures 5–13 watts 14–26 watts Incandescent Basecase (27–65 watts) Incandescent Basecase (66–90 watts) Incandescent Basecase (> 90 watts) Mercury Vapor Basecase (27–65 watts) Mercury Vapor Basecase (66–90 watts) Mercury Vapor Basecase (> 90 watts) L-C. Induction Lamps and Fixtures 55–100 watts > 100 watts L-D. T-8 or T-5 Linear Fluorescent Lamps with Electronic Ballasts * Lamp Installation - 2-foot lamp * Lamp Installation - 3-foot lamp * Lamp Installation - 4-foot lamp * Lamp Installation - 8-foot lamp * Delamping - 2-foot lamp Delamping - 3-foot lamp Delamping - 4-foot lamp Delamping - 8-foot lamp L-E. HID Fixtures Interior Pulse Start HID, Incandescent Basecase (0–35 watts) Interior Pulse Start HID, Incandescent Basecase (36–70 watts) Interior Pulse Start HID, Incandescent Basecase (71–100 watts) Interior Pulse Start HID, Incandescent Basecase (101–175 watts) Interior Pulse Start HID, Incandescent Basecase (176–250 watts) Interior Pulse Start HID, Incandescent Basecase (251–400 watts) Interior Pulse Start HID, Mercury Vapor Basecase (0–35 watts) Interior Pulse Start HID, Mercury Vapor Basecase (36–70 watts) Interior Pulse Start HID, Mercury Vapor Basecase (71–100 watts) Interior Pulse Start HID, Mercury Vapor Basecase (101–175 watts) Interior Pulse Start HID, Mercury Vapor Basecase (176–250 watts) Interior Pulse Start HID, Mercury Vapor Basecase (251–400 watts) 12/28/2004 F - 10 $1.50/lamp $3.50/lamp $6.00/lamp $4.25/lamp $9.00/fixture $11.00/fixture $12.50 / fixture $18.00 / fixture $22.50 / fixture $11.50 / fixture $17.00 / fixture $21.50 / fixture $35.00/lamp $50.00/lamp $3.50/lamp $4.25/lamp $4.25/lamp $7.50/lamp $4.00/lamp $4.00/lamp $6.00/lamp $9.00/lamp $18.00/fixture $25.00/fixture $40.00/fixture $40.00/fixture $40.00/fixture $50.00/fixture $12.50/fixture $18.00/fixture $38.00/fixture $38.00/fixture $38.00/fixture $48.00/fixture Version 1.0 Measures L-E. HID Fixtures Exterior Pulse Start HID, Incandescent Basecase (0–100 watts) Exterior Pulse Start HID, Incandescent Basecase (101–175 watts) Exterior Pulse Start HID, Incandescent Basecase (>=176 watts) Exterior Pulse Start HID, Mercury Vapor Basecase (0–100 watts) Exterior Pulse Start HID, Mercury Vapor Basecase (101–175 watts) Incentive Rate Exterior Pulse Start HID, Mercury Vapor Basecase (>=176 watts) L-F. Ceramic Metal Halide (CMH) L-G. Interior High Bay Linear Fluorescent Four Lamp T5 or Six Lamp T5, T8 Fixtures L-H. Interior Metal Halide Pulse Start Retrofit Fixtures L-I. Occupancy Sensors Wall-box lighting sensor Wall or ceiling-mounted lighting sensor High Bay Lighting Sensor L-J. Photocells L-K. Time Clocks L-L. LED Exit Signs L-M. Channel Signs (LED) Indoor <=2 ft. Outdoor <=2 ft. Indoor > 2 ft. Outdoor > 2 ft. $48.00/fixture $25.00/fixture $75.00/fixture $45.00/lamp $36.00/fixture $64.00/fixture $100.00/fixture $22.00/fixture $30.00/fixture $16.50/sensor $44.00/sensor $44.00/sensor $7.00/photocell $36.00/time clock $27.00/fixture $4.00/ft. $2.00/ft. $6.00/ft. $3.00/ft. Other HVAC Itemized Measures H-A. Package Terminal Air Conditioners and Package Terminal Heat Pumps (up to 24,000 Btu/hr) H-B. Setback Programmable Thermostats H-C. Reflective Window Film Coastal Inland Desert H-D. Advanced Evaporative Coolers H-E. Variable Frequency Drives HVAC Fans with Motors <= 100 HP $100.00/unit $54.00/unit $1.35/square ft. $1.35/square ft. $1.35/square ft. $123.00/ton $80.00/hp Food Service Itemized Measures F-A. Connectionless Steamers full load efficiency 50% or greater full load efficiency 70% or greater F-B. Insulated Holding Cabinets full size cabinet full size cabinet energy rate less or equal to 0.5 kW three-quarter size cabinet three-quarter size cabinet energy rate less or equal to 0.4 kW half size cabinet half size cabinet energy rate less or equal to 0.3 kW 12/28/2004 F - 11 $750.00/unit $900.00/unit $458.00/unit $733.00/unit $367.00/unit $550.00/unit $275.00/unit $367.00/unit Version 1.0 Measures Incentive Rate Other Technologies Itemized Measures OT-A. Sprinkler to Drip Irrigation (Well or No Well) Field/Vegetables Deciduous Trees Vineyard OT-B. Low Pressure Sprinkler Nozzles (Portable and Permanent Installations) Central Valley Coastal $44.00/acre $44.00/acre $44.00/acre $1.15 nozzle $1.15 nozzle Refrigeration Itemized Measures R-A. Night Covers for Display Cases Low Temperature Case Medium-Temperature Case R-B. Strip Curtains for Walk-In Boxes R-C. Glass Doors on Open Display Cases (Low Temperature) R-D. Glass Doors on Open Display Cases (Medium Temperature) R-E. New Refrigeration Display Case with Doors (Low-Temperature Case) R-F. New Refrigeration Display Case with Doors (Medium-Temperature Case) R-G. New High Efficiency Refrigeration Display Case with Special Doors (Low Temp) R-H. Special Doors with Low/No Anti-Sweat Heat on Low Temp Display Cases R-I. Anti-Sweat Heater (ASH) Controls R-J. Insulation for Bare Suction Lines R-K. Door Gaskets on Solid Doors For Cooler For Freezer R-L. Door Gaskets on Glass Doors R-M. Auto-Closers for Main Cooler Doors R-N. Auto-Closers for Main Freezer Doors R-O. Evaporator Fans Controller for Walk-in Coolers R-P. Air-Cooled to Evaporator-Cooled Condenser Conventional Multiplex R-Q. Energy Efficient Condenser Air-Cooled Evaporative-Cooled R-R. High Efficiency Multiplex Compressor System Air-Cooled Evaporative-Cooled R-S. High Efficiency Multiplex Compressor System with Efficient Condenser Air-Cooled Evaporative-Cooled $4.00/linear ft $4.00/linear ft $4.00/linear ft. $40.00/closer $50.00/closer $75.00/controller $195.00/ton $195.00/ton $175.00/ton $75.00/ton $300.00/ton $300.00/ton $300.00/ton $300.00/ton R-T. Vending Machine Controller R-U. Efficient Evaporator Fan Motor Electronically Commutated Motor (ECM) R-V. Efficient Evaporator Fan Motor Permanent-Split Capacitor (PSC) Motor 12/28/2004 $9.00/linear ft. $9.00/linear ft. $3.00/square ft. $150.00/door $75.00/door $200.00/linear ft $150.00/linear ft. $200.00/linear ft. $50.00/door $14.00/linear ft. $1.00/linear ft. F - 12 $90.00/controller $20.00/motor $15.00//motor Version 1.0 Measures Incentive Rate Natural gas Itemized Measures (not applicable for SCE customers) G-A. Commercial Clothes Washer G-B. Storage Water Heater G-C. Space Heating Boiler Steam Water Large G-D. Commercial Boiler G-E. Instantaneous Water Heater G-F. Process Boiler Steam Water G-G. Commercial Pool Heaters G-H. Direct Contact Water Heater G-I. Pipe Insulation (minimum 2” thick) G-J. Tank Insulation (minimum 2” thick) G-K. Greenhouse Heat Curtain G-L. Infrared Film for Greenhouses G-M. Setback Programmable Thermostats G-N. Low-Flow Pre-Rinse Spray Valves $1.50/MBtuh $2.00 /MBtuh $1.00 /MBtuh $1.00 /MBtuh $1.00 /MBtuh $1.50/MBtuh $2.00/MBtuh $2.00/MBtuh $2.00/MBtuh $2.00/MBtuh $2.00/MBtuh $3.00/linear ft $3.00/square ft $0.40/square ft $0.03/square ft $54.00/unit $30.00/unit * For projects that include T-12 to T-8 fluorescent lighting replacement, the application must include other measures that account for at least 20 percent of the project’s total energy savings. 12/28/2004 F - 13 Version 1.0