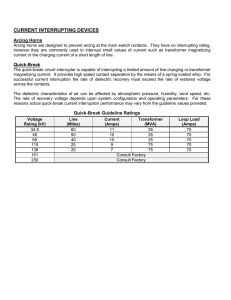

properties of transformer oil that affect efficiency.

advertisement