Development of dielectric spectroscopic sensor for contaminant

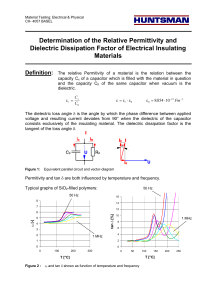

advertisement