NEW 2013 Product Catalogue

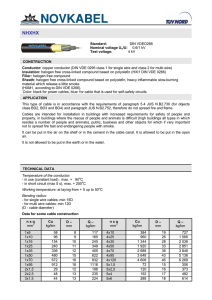

advertisement