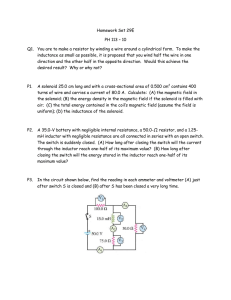

Energy Loss of an Inductor

advertisement

ENERGY LOSS OF AN INDUCTOR Stefano Medved Enerdoor Products Manager JACKSONVILLE, FL January 22, 2016 1 OVERVIEW • VFD’s and Motors - The Challenge • Inductance - Theory • Inductance - Real • Laboratory Testing • Market Applications 2 VFD’S & MOTORS • VFD Output = PWM • Similar dv/dt regardless of output frequency • Motor Potential • Break down of winding insulation. • Arc to motor bearing • Decreased life 3 VFD’S & MOTORS Solution – Reduce the dv/dt, and prolong the life of the motor. This is old news: 4 INDUCTANCE - THEORY E: Magnetic Field An inductor, also called a coil or reactor, is an electrical component that creates a magnetic field when current flows through it. An ‘ideal inductor’ has inductance, but no resistance or capacitance, and does not dissipate or radiate energy. The energy loaded from an inductor is: E = ½ L I2 E = Energy L = Inductance I = Current 5 INDUCTANCE - THEORY Q: Quality Factor The quality factor, or Q is the ratio of its inductive reactance to its resistance at a given frequency while measuring the efficiency. The higher Q factor of the inductor, the closer it is to being considered an ideal or low loss inductor: Q= ω𝐿 𝑅𝑅 Q = Quality Factor ω = Resonance L = Inductance 𝑅𝑅 = 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 P: Power Loss The Q factor increases linearly at low frequencies if L and R are constant, however, the parameters vary with frequency. The energy loss on the wire is mostly due to electrical resistance. The power loss would be: P=R·I2 P = Power Loss 𝑅 = 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 𝐼 = 𝐶𝐶𝐶𝐶𝐶𝐶𝐶 6 INDUCTANCE – THEORY B: Magnetic Flux A measure of the strength of a magnetic field over given area perpendicular to it, equal to the product of the area and magnetic flux density 𝑁𝑖 B=µ 𝑙 B =magnetic flux µ =magnetic permeability N= number of turns of the inductor l = length of the magnetic ride 7 INDUCTANCE - REAL However, a real inductor has energy losses Considerations: • Resistance of the wire • Inductor core material • Parasitic capacitance Theory Theory in Practice 8 INDUCTANCE - REAL Resistance of wire • Material & cable length P = Resistivity L= 𝐿𝐿𝐿𝐿𝐿𝐿 A = Cross Sectional Area • Considered negligible if cross sectional area is sized correctly • Source: http://hyperphysics.phy-astr.gsu.edu/hbase/electric/resis.html Resistance v. Frequency Copper Aluminum Silver Relative resistance versus temperature • At 20ºC resistance is 1 • At 150ºC resistance is 1.5 9 INDUCTANCE - REAL Resistance of wire • Change in Cross Sectional Area v. Frequency Frequency - Skin effect Impedance on the cross sectional area of a power cable increases linearly with the increase of frequency Note: Skin effect occurs regardless of material Example: At 60Hz the copper skin depth is 10mm At 1Khz the copper skin depth is 2mm Impedance Level Low Medium High 10 INDUCTANCE - REAL Resistance of wire Example: Power loss of AWG2/0 cable @ 240A Conclusion • Number of conductors is important • Frequency level is important 11 LABORATORY TEST Setup – Equipment For Analysis 2ft 20ft Load Reactor Transformer 480Vac 3-phase High Frequency VFD 480Vac – 150A Frequency output 0-3500Hz PRODUCT A 3-phase load reactor V = 480Vac L = 2.4mH I = 25 A Core Material: Iron laminate High Frequency Rated Motor 15HP PRODUCT B 3-phase high frequency load reactor V = 480Vac L = 2.4mH I = 25 A Core Material: high frequency material LABORATORY TEST Setup – Measurements Determined two most important factors: • Power Loss • Quality Analyzer - Input Power • Inductor Temperature • Temperature Sensors - Inductor Core - Copper Winding LABORATORY TEST Core Material product A Power loss of Iron Core Inductor @ 480Vac v. Frequency At 50Hz: Power loss is 1.01W/Kg At 500Hz: Power loss is 24.66W/Kg 14 LABORATORY TEST Core Material product B Power loss of HF Core Inductor @ 480Vac v. Frequency At 50Hz: Power loss is At 500Hz: Power loss is 3.5W/Kg High performance material reduces power loss by 84% at 500Hz 15 LABORATORY TEST Energy Loss Summary Laminated Inductor & High Frequency Inductor Energy Loss v. Frequency 16 LABORATORY TEST Temperature Testing • • Wire Temperature Laminate Temperature Laminated Inductor & High Frequency Inductor at 300Hz Note: Ambient Temperature = 73ºF 17 LABORATORY TEST Energy Loss Calculations • If the inductor temperature is greater than ambient, energy losses are present. • Heat Measurement = BTU (British Thermal Unit) • Energy required to raise the temperature of a given mass of material: E = Energy ΔT = Temperature Change m = mass of copper Cp = Material Specific Gravity • 1 Joule = 0.00095 BTU 18 LABORATORY TEST Energy Loss Calculations Power Dissipated as Heat - BTU Calculation Results Frequency Product A - Standard Reactor Product B – HF Reactor 120Hz 1630 BTU 1050 BTU 300Hz 3067 BTU 1108 BTU 550Hz 5163 BTU 1170 BTU Additional heat within a cabinet requires power for temperature conditioning within an enclosure 14x14x12: • 1000 BTU/Hr is 300W • 3400 BTU/Hr is 1000W • 5000 BTU/Hr is 1500W Source: Hoffmann – Pentair – series S06 19 LABORATORY TEST Energy Loss Summary Test at 60Hz Temperature Power loss Heat dissipation Total power consumption Standard load Reactor 140°F 360W 300W 660W High Frequency Reactor 80°F 308W 300W 608W Δ difference -60°F -52W (17%) 0W -52W ( 17%) Test at 300Hz Temperature Power loss Heat dissipation Total power consumption Standard load Reactor 230°F 900W 1000W 1900W High Frequency Reactor 80°F 330W 300W 630W Δ difference -150°F -570W (63%) -700W ( 70%) -1270W ( 67%) Test at 550Hz Temperature Power loss Heat dissipation Total power consumption Standard load Reactor >250°F 1515W 1500W 3015W High Frequency Reactor 80°F 343W 300W 643W Δ difference NA°F -1172W (78%) -1200W (80%) -2372W ( 79%) MARKET APPLICATIONS 50/60Hz Greater than 60Hz Conveyer controlled by VFD High speed spindle motor Low speed motor CNC machine Automatic machine with VFD High speed pump Motor pump low speed Machine Tools – Wood Machinery Centrifuge Medical MARKET APPLICATIONS • dV/dt and overvoltage spikes damage bearing and winding insulation reducing motor life • Typical load reactor that reduce the dV/dt and overvoltage spikes increasing the motor life. Measurement between VFD and motor Measurement between VFD and motor with load reactor MARKET APPLICATIONS • Sine wave filter installed. dV/dt and overvoltage spikes completed eliminate. • Enerdoor snubber: A new technology way to protect dV/dt and overvoltage phase- phase and phase-ground. Compact parallel device with low power loss Measurement between VFD and motor with sine-wave filter *Measurement taken between VFD and motor with Enerdoor snubber. Questions? (P) 207-210-6511 (F) 207-210-6512 04103 Portland, ME - USA www.enerdoor.com info@enerdoor.com 24