owner`s manual - BOSS Snowplow

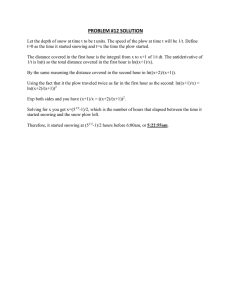

advertisement