Services | Modernizations | Filtration

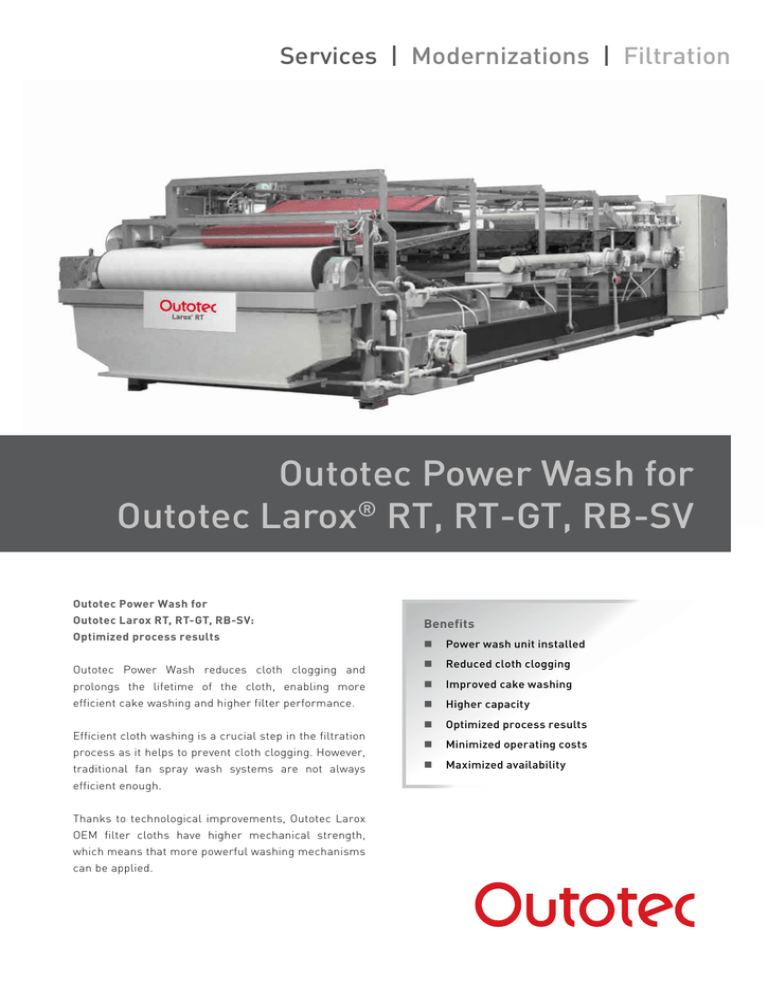

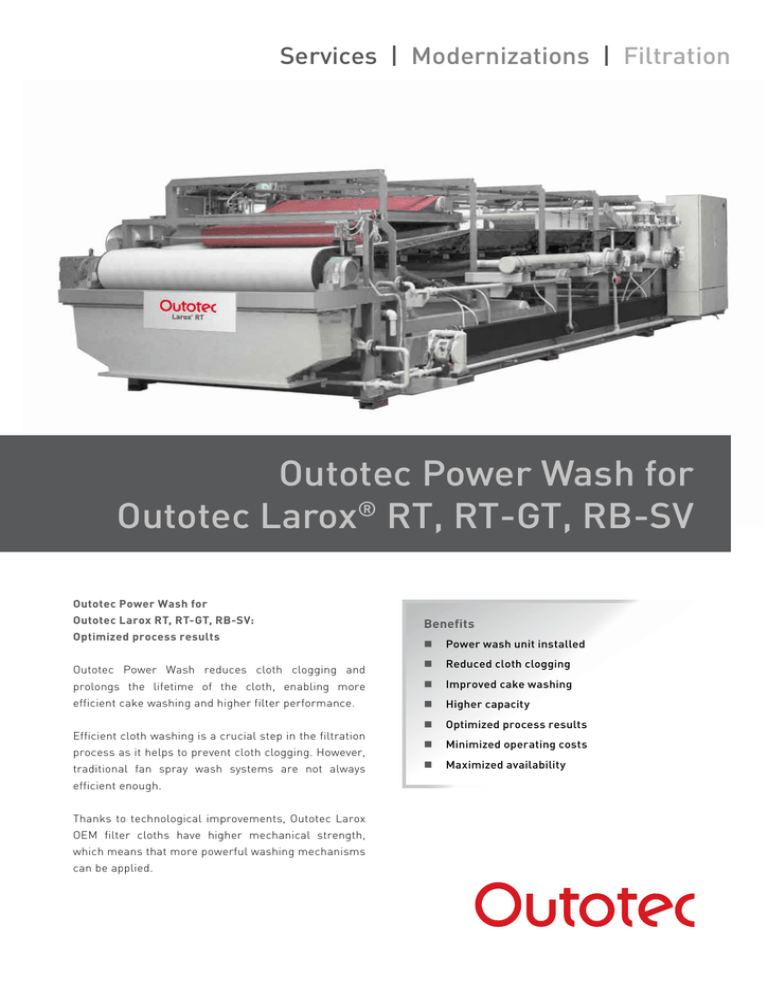

Outotec Power Wash for

Outotec Larox® RT, RT-GT, RB-SV

Outotec Power Wash for

Outotec Larox RT, RT-GT, RB-SV:

Optimized process results

Outotec Power Wash reduces cloth clogging and

Benefits

Power wash unit installed

Reduced cloth clogging

prolongs the lifetime of the cloth, enabling more

Improved cake washing

efficient cake washing and higher filter performance.

Higher capacity

Efficient cloth washing is a crucial step in the filtration

process as it helps to prevent cloth clogging. However,

traditional fan spray wash systems are not always

efficient enough.

Thanks to technological improvements, Outotec Larox

OEM filter cloths have higher mechanical strength,

which means that more powerful washing mechanisms

can be applied.

Optimized process results

Minimized operating costs

Maximized availability

Additional washing for improved results

Outotec Power Wash is an additional, oscillating ­high

pressure cloth wash unit, developed for Outotec Larox

RT (Pannevis) Horizontal Vacuum Belt Filters for

enhanced cloth washing.

The Power Wash uses a shower system with needle jet

nozzles which achieve optimal wash results in one go.

More efficient washing improves process results in many

ways. Reduced cloth clogging keeps the performance

and capacity of the belt filter at a high level. Cake

washing is improved and lower cake moisture content

can be achieved.

Efficient washing helps reduce operating costs by

prolonging the lifetime of the filter cloth, thus reducing

both downtime and cloth change frequency. In most

cases, Outotec Power Wash reduces the overall wash

water consumed by the belt filter. .

System summary

Other options

The Power Wash unit consists of a shower system, an

nn

Brush cleaning for shower system

oscillator device, an additional sieve for the filtration

nn

Inverter control for high pressure

of the washing water, and an optional high pressure

pump (enabling pump pressure and

pump.

The optional high pressure pump is designed to provide

washing water pressure from 20 up to 100 bar, and

a flow rate of 120 l/min. The correct pressure will be

determined according to the filter cloth and process

conditions.

The shower system unit is installed in the feed end of

the filter, and operated via the OIU of the filter or the

plant automation system. Washing technology is based

on oscillating high velocity nozzles (needle jet). The

needle is directed according to the weave of the cloth to

guarantee the best wash result.

The installation is quick and easy, requiring a maximum

downtime of only 8 hours. During the installation, the

unit is adjusted to meet the specific process conditions

and requirements.

wash water volume adjustments)

nn

Oscillation frequency converter

nn

Vat for collection of the washing water

63

63

62

62

62

92

88

97

92

88

Filter Performance Level Reduction due to Cloth Clogging

Restored performance (with Power Wash)

100

Filter Performance Level (%)

90

80

Original performance

70

60

50

Filter

Filter

With Power Wash, the original

performance level of the cloth

(and of the filter) can be restored.

The washing frequency depends

on the process conditions and cloth

clogging speed. It can be once /shift,

once / day or even once / week.

40

30

20

10

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Time

Case study on water savings

The overall water saving: 63 m 3 /week (19 %)

According to a case study made by Outotec on a Outotec

In this case study:

Larox RT 2100 filter, adding the Outotec Power Wash

unit achieved important savings in the overall water

nn

Power Wash washing pressure was 20 bar

consumption.

nn

Power Wash water usage was 7.2 m3/h

nn

Power Wash washing time 3h / wash

nn

Power Wash frequency once per week

nn

Normal wash water usage 2 m3/h -> 336 m3/week

nn

Normal wash water usage after installation of the

(21 m3/week)

Outotec Power Wash 1.5 m /h -> 252 m /week

3

nn

3

Total wash water usage (including water used

by the Outotec Power Wash) -> 273 m3/week

Short payback time

The payback time based on references in Finland has

Outotec provides custom modernizations for all Outotec

been approximately one year (calculated based on cloth

installations. These modernizations help improve

usage only). If improved process results are taken into

equipment

account the pay-back time is much shorter.

results. Please c­ontact your local Outotec office for

performance,

more information.

availability

and

process

Finland, September 2012.

Outotec develops and provides technology solutions for the sustainable use of Earth’s natural

resources. As the global leader in minerals and metals processing technology, Outotec has developed

over decades several breakthrough technologies. The company also offers innovative solutions for

the chemical industry, industrial water treatment and the utilization of alternative energy sources.

Outotec shares are listed on the NASDAQ OMX Helsinki.

services@outotec.com

www.outotec.com

Copyright © 2012 Outotec Oyj. All rights reserved.