Lighting Industry

advertisement

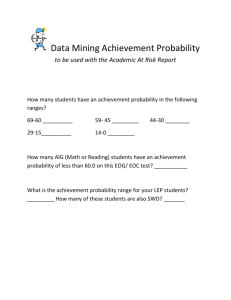

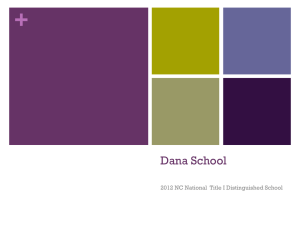

PLASMA LIGHTING O ver the last several years, LEDs have been the “it” technology in the lighting world. LIGHTFAIR is seemingly dominated by LED companies; the federal government under the auspices of the DOE has an extensive program in place to support LED applications; and even the mainstream media has devoted major coverage to LEDs as a potential replacement technology for incandescent. LEDs, however, are not the only emerging light source. Another technology— light emitting plasma (LEP) —is gaining Photos courtesy of Luxim The Plasma Paradigm Light emitting plasma is on the rise in high-illuminance applications traction as a viable system for high-illuminance applications, specifically as a replacement for 400-W-plus metal halide and high-pressure sodium systems, by offering the same delivered lumens using about 40 percent less energy. It’s not only the lighting industry that’s taking notice. Forbes magazine included an article last year on LEP, while the Wall Street Journal recognized Luxim, a LEP developer based in Silicon Valley, as one of its “Top 10 Clean Tech Companies” in the U.S. Aside from the energy savings, LEP has a number of other important attributes, ranging from dimmability, to expected lifetime, to color. LEP can be dimmed to 20 percent output allowing further energy savings. In addition, LEP has a projected 50,000-hour life at 70 percent lumen maintenance. This compares favorably to 18,000 hours for metal halide. LEP lamps are available today at a color temperature of 5,200K with warmer color temperatures expected BY RANDY REID AND APURBA PRADHAN shortly (Luxim, for example, demonstrated 4,800K systems at LIGHTFAIR). Finally, LEP delivers a continuous spectrum ensuring high color quality; systems are available today at 75, 80 and 95 CRI. 56 October 2011 | LD+A www.ies.org PLASMA LIGHTING Figure 1 HOW LEP WORKS The term plasma is used in the industry which are typically the weakest link of an HID lamp A number of fi xture companies have designed reflectors that capitalize on the to describe sources with a continuous • Elimination of quartz wall darkening, a compactness of the LEP source. These spectrum. The LEP system (Figure 1) com- source of lumen depreciation and fail- reflectors direct light to the work plane prises three components: emitter, driver ure, as electrode material evaporates and offer much better uniformity and a and power supply. The emitter consists of and deposits on the transparent sur- more even distribution than traditional a quartz capsule embedded in a ceramic face of lamp. HID. These improvements allow street- puck. Inside the capsule is a blend of gas- • Elimination of molybdenum foils allow- light pole spacing, for example, to be ex- ses and halides designed to emit a certain ing faster warm-up and restrike times panded from 100 ft (typical of HPS) to 150 spectrum. A highly reflective material As a result, over the years, there has ft while maintaining IES Recommended placed between the capsule and the puck, been a great deal of interest in plasma Practices. On new construction, this re- causes the light to emit in a forward pattern. light sources. The wireless revolution has duction of fi xtures and poles allows LEP The driver, which is essentially a solid- provided cost effective, efficient and reli- to have lower capital costs and lower state RF amplifier, creates electrical en- able solid-state amplifiers that make LEP operating costs compared to legacy tech- ergy that is fed into the puck by a coaxial light sources possible today. nologies (Figure 2). cable. The ceramic puck then focuses that energy onto the capsule, energizing the mixture inside and causing the LEP lamp to emit brilliant white light. A quartz capsule is at the heart of the “Real-world” lighting efficiency is an- DIRECTIONALITY AND POINT SOURCE other important consideration with any On the applications front, a single LEP emerging light source. As these new tech- source, only a few millimeters in size, can nologies become available, lighting design- produce the light needed for a complete ers and end users learn how to assess the LEP system. This simple construction has luminaire. Because the source is compact technology’s benefits. A hard-learned les- no electrodes, no glass-to-metal seals and directional, light can be harvested son from LED implementations is that it is and no alien materials inside the capsule. from it more effectively than from induc- not the light on the datasheet that matters This simplicity and purity of construction tion, LED or HID. The directional source but the light on the ground. For many rea- gives the LEP emitter its efficiency and prevents light from being trapped and sons light on the ground can be less than ruggedness. This simple design has the wasted in the luminaire. The point source the datasheet might lead one to believe following benefi ts: optics effectively and uniformly map the (operating temperature, fixture efficiency, • Elimination of energy wasted as heat source to an illuminated area prevent- measurement discrepancy, binning varia- ing unwanted light spill which can cause tion). There are also reasons why light on glare and light pollution. the ground may be higher than quoted on in the electrodes themselves • Elimination of glass-to-metal seals www.ies.org LD+A | October 2011 57 PLASMA LIGHTING the datasheet but these cases seldom intrude on real-life experience. Today LEP fi xtures deliver system efficiencies above 70 lumens per watt with excellent backlight, uplight and glare control. Furthermore, LEP fi xtures in development can deliver circa 90 lumens per watt. These figures compare favorably with best-in-class LED fi xtures on the market and on the drawing board today. Significantly, for outdoor applications, LEP has excellent mesopic and scotopic lumens. In fact, LEP had the highest scotopic/photopic ratio of all sources tested in preparation for the new IES Lighting Handbook (10 th Edition). For the first time, this new edition includes guidelines to account for the improved nighttime visibility that comes with full spectrum sources. Figure 2 This allows further energy savings using LEP in outdoor applications. COMPLEMENT NOT COMPETITOR LED and LEP is not an either/or proposition. In high-illuminance applications in particular, LEP can serve as high-output complement to LED. Both technologies offer efficiency, life and digital control. The basic building block of LED systems is the LED chip with an output of circa 100 lumens. The basic building block of LEP is the quartz emitter with an output of 20,000 lumens. Given this starting point, one can envisage a family of fixtures that uses LED for low and medium illuminance and expands to LEP for high illuminance. Inside this broad positioning, LEP has Roadway lighting is among the suitable applications for LEP. unique advantages where small form factor is important. These include high-mast systems (compactness reduces wind load), portable systems (compactness simplifies transportation and setup) and 58 October 2011 | LD+A www.ies.org PLASMA LIGHTING A single LEP source, only a few millimeters in size, can produce the light needed for a complete luminaire. The directional source prevents light from being trapped and wasted in the luminaire. beam systems (compactness simplifies costs are falling rapidly and are projected optical design). to match the costs of mainstream HID lu- rays of LEDs, bigger heat sinks and a larger minaires by FY 2013. fixture. In short, LED scales down well. LEP Finally, there is the question of cost. Because its architecture is based on a LED does have an advantage over LEP single emitter and a single driver, LEP has in its ability to scale down. If a job calls for lower cost than LED in high-illuminance a 3,000 lumens, the LEP system would still applications. While costs vary by vendor, require an emitter, driver and power supply quantity and terms broadly speaking we and would therefore have approximately see LED and LEP systems having similar the same cost as a 20,000-lumen LEP sys- costs at about a 5,000-lumen output level. tem. In this particular case, LED would be As output increases, however, LED costs a more cost-effective solution because it scale proportionately while LEP costs scales down well. On the other hand, if the remain relatively flat. This provides LEP job called for a 45,000 lumens, LEP still has with a significant cost advantage at the the same three components and similar 20,000-lumen level. Furthermore, LEP cost. By contrast, for LED to scale up, the www.ies.org manufacturer would have to add more ar- scales up well. Q THE AUTHORS Randy Reid, Member IES (1995), is the vice president of marketing for Luxim, a developer of light emitting plasma. Mr. Reid is a past-president of the IES (2002-03) and was chairman of the 2010 IES Annual Conference held in Toronto. Apurba Pradhan, Member IES (2009), is the director of product marketing at Luxim. LD+A | October 2011 59