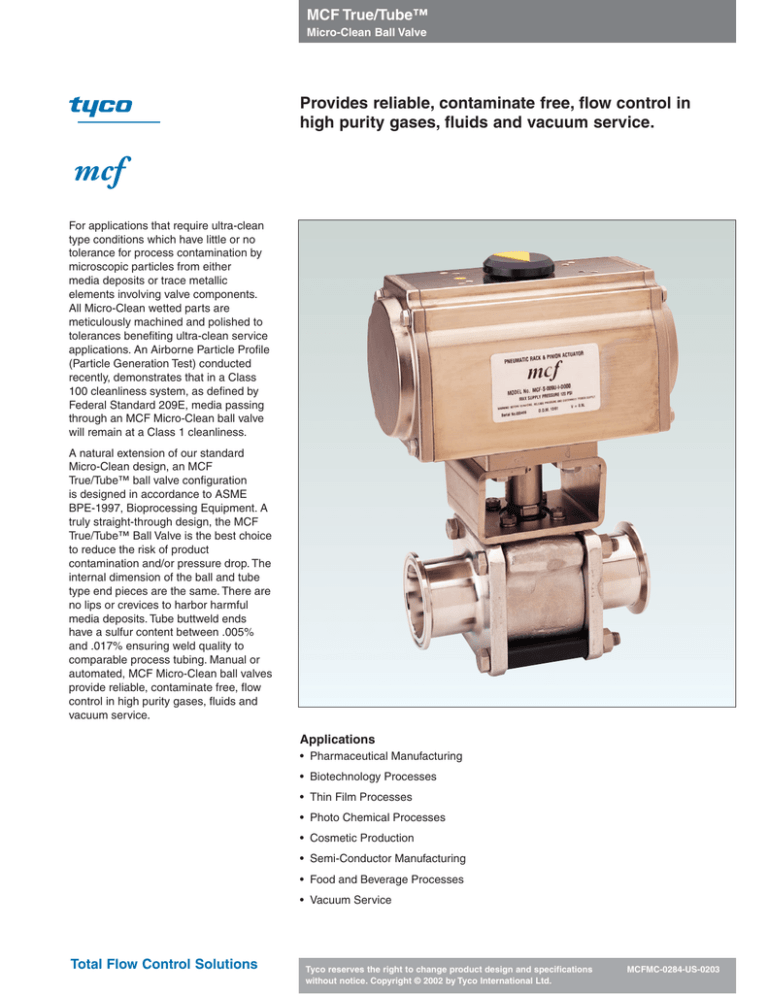

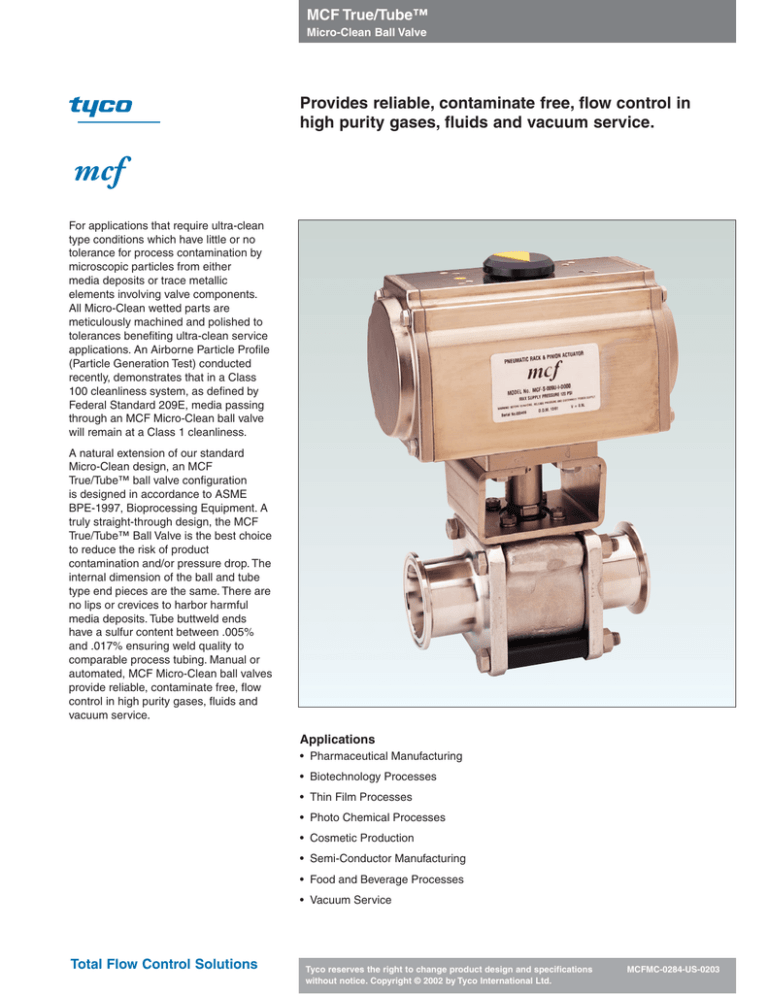

MCF True/Tube™

Micro-Clean Ball Valve

Provides reliable, contaminate free, flow control in

high purity gases, fluids and vacuum service.

mcf

For applications that require ultra-clean

type conditions which have little or no

tolerance for process contamination by

microscopic particles from either

media deposits or trace metallic

elements involving valve components.

All Micro-Clean wetted parts are

meticulously machined and polished to

tolerances benefiting ultra-clean service

applications. An Airborne Particle Profile

(Particle Generation Test) conducted

recently, demonstrates that in a Class

100 cleanliness system, as defined by

Federal Standard 209E, media passing

through an MCF Micro-Clean ball valve

will remain at a Class 1 cleanliness.

A natural extension of our standard

Micro-Clean design, an MCF

True/Tube™ ball valve configuration

is designed in accordance to ASME

BPE-1997, Bioprocessing Equipment. A

truly straight-through design, the MCF

True/Tube™ Ball Valve is the best choice

to reduce the risk of product

contamination and/or pressure drop. The

internal dimension of the ball and tube

type end pieces are the same. There are

no lips or crevices to harbor harmful

media deposits. Tube buttweld ends

have a sulfur content between .005%

and .017% ensuring weld quality to

comparable process tubing. Manual or

automated, MCF Micro-Clean ball valves

provide reliable, contaminate free, flow

control in high purity gases, fluids and

vacuum service.

Applications

• Pharmaceutical Manufacturing

• Biotechnology Processes

• Thin Film Processes

• Photo Chemical Processes

• Cosmetic Production

• Semi-Conductor Manufacturing

• Food and Beverage Processes

• Vacuum Service

Total Flow Control Solutions

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284-US-0203

MCF True/Tube™

Micro-Clean Ball Valve

Stainless steel handle for valves up to 2"

in size. For larger valves the lever

handle is epoxy coated CS, with S.S.

lever handle optional.

Features

Self-adjusting stem packing assembly

with saddle type lock washer. Live

loading, it automatically adjusts for

thermal contraction and expansion.

Pressure loaded PTFE seats.

Low torque design gives a

bubble-tight seat even in bidirectional flow. Other materials

available for specific media, high

pressure and/or high temperature

applications. (Optional cavity

fillers available for all sizes.)

For ultra-pure applications, enhanced or

reinforced PTFE stem seals can be supplied. An

internal anti-static design using glass filled

graphite contact washers is available for volatile

or flammable applications.

Bottom entry “blow out proof” stem.

Precision fit 316L stainless steel

design for maximum operating safety.

End pieces in 316L stainless

steel.1 Three piece construction

eliminates the need for unions

and allows complete versatility of

optional end connections in KCE

(Kuick Connect Ends), or TBX

Tube Buttweld Extended End2).

Fully encapsulated seals - standard. Prevents

leakage to atmosphere or in vacuum service to

media. Allows welding in-line without

disassembly.

Stainless steel body.1

Precision machined solid 316L

stainless steel ball with provision

for valve cavity relief.

Notes

In-line maintenance. One bolt removal

(swing out design) for simplified in-line

maintenance of all internal parts.

Single bolt removal also minimizes

pipe twisting or distortion during

maintenance.

1. All MCF stainless steel valve bodies, end

pieces and internal component parts are

passivated (cleaned to remove scale,

machining oils, debris, dirt and grease) to

further ensure their protection against

corrosion. This may include a pickling

process prior to passivation.

2. Tube ends have a sulfur content between

.005% and .017% ensuring weld quality to

comparable process tubing.

Time and labor saving advantages of

MCF’s direct (ISO 5211 Type) mounting

pad include:

• Easy installation of actuators using

stem coupler, bracket and mounting

pad bolts which are readily available

from MCF Valves.

• Reduced stem wear due to continuous

“true” stem alignment.

• Elimination of torsional stress effects

on bolting and end pieces commonly

associated with “body bolt” bracket

type mounts.

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

2

• In-line maintenance without having to

remove operators. MCF’s 3-piece

swing out design retains the one bolt

removal feature for inspection or

replacement of internal component

parts. Larger valves use a similar “lift

out” design.

MCF True/Tube™

Micro-Clean Ball Valve

T/T - True/Tube™ Ball Valve

A truly straight-through design, the

configuration of MCF’s True/Tube™ Ball

Valve is the best choice to reduce the

risk of product contamination and/or

pressure drop. The internal dimension of

the ball and tube type end pieces are the

same. There are no lips or crevices to

harbor harmful media deposits.

Options

S.I.P. and C.I.P. Valves

Steam-in-Place (S.I.P.) and

Clean-In-Place (C.I.P.) valves with

purge ports for inline cleaning. Used as a

supplement to routine maintenance programs

they quickly and efficiently flush residue or

contaminates that can not be allowed to build

up in ultra pure Micro-Clean applications.

Extended Stem With Latch Locking Handle and Locking Device

Fully complies with OSHA safety regulations.

While MCF Valve‘s extended stem housing

raises the latch locking handle and locking

device well above insulation requirements for

easy access. The added feature of a locking

device adds security in “Lock Out/Tag Out”

operations. Conversion to an automated valve

is simply a matter of removing the latch

locking handle and replacing it with an MCF

bracket and properly sized MCF actuator.

Solenoid and limit switches are readily

available and easily adapted to manual or

automated valve packages.

Micro-Clean valve with extended stem housing,

latch locking handle and locking device

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

3

MCF True/Tube™

Micro-Clean Ball Valve

Parts and Materials

1/2”

to 11/2”

Part Quantity Component

No.

Description

Stainless Steel

Ball Valves

1

1

Body

A182-316L - 1/2” to 2”1

A351-CF8M - 21/2” to 4” (A182 316L Optional)

2

1

Ball

A182 F316L1

3

1

Stem

A182 F316L1

4

2

Body Seal

Virgin PTFE1

5

2

Seat

Virgin PTFE1

6

2

Stem Seal

Glass Filled PTFE1

7

2 or 3

Anti-Static Seal Assembly2

Graphite and Glass Filled PTFE

8

1

Stem Seal Follower

A182 F316L

9

2

Belleville Washer

A182 F304

10

4

Body Bolt

F593-GRP1

11

4

Nut

F594-GRP1

12

1

Gland Nut

A182 F304

13

2

Distance Piece

Reinforced PTFE/Graphite

14

2

End Piece

A182-316L/A351-CF3M3

15

1

Handle

304 SS

16

1

Saddle Washer

A182 F304

17

1

Tab Washer

A182 F304

18

1

Stem Nut

A182 F304

2” to 4”

19

2

Seat Centering Ring

20

6

8

21/2”)

21

12

16

22

Glass Filled PTFE1

Body Bolt (2” Body Bolt (3” - 4”)

F593 GRP1

F593 GRP1

Nut (2” - 21/2”)

Nut (3” - 4”)

F594-GRP1

F594-GRP1

1

Handle

A105 Epoxy Coated1

23

1

Handle Washer

A182 F304

24

1

Handle Bolt

A182 F304

Notes

1. Other materials available. Consult the factory.

2. Non anti-static packing (NAP) is available for

ultra pure applications.

3. Tube buttweld ends have a sulfur content

between .005% and .017% ensuring weld

quality to comparable process tubing.

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

4

MCF True/Tube™

Micro-Clean Ball Valve

Parts and Materials

1/2”

to 11/2” Size True/Tube™ Micro-Clean Valves

16

18

12

17

9

15

8

6

11

7

1

2

14

4

5

10

5

4

14

13

6

3

2" to 4" Size True/Tube™ Micro-Clean Valves

12

24

23

16

22

8

21

7

1

19

14

2

20

14

4

5

21

5

19

6

3

4

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

5

MCF True/Tube™

Micro-Clean Ball Valve

Dimensions

K

J

L

P

O

D

Kuick Connect End

O

P

mcf

Open

Close

Tube Type Buttweld Extended

F

A

C

H

D1

Tube Type - Buttweld End

Valve

Size

Port

Inches

A

C

D

D1

O.D. Tube

KCE

TBX

F

H

J

Thread

K

L

O

I.D.

KCE TBX

P

O.D.

KCE TBX

Weight (lb)

KCE TBX

Std. Std.

1/2

0.37

3.75

0.80

3.50

5.75

4.92

2.25

3/8

UNF

0.21

0.35

0.37

0.37

0.99

0.50

1.3

1.2

3/4

0.62

4.73

1.24

4.25

6.50

7.09

3.00

7/16

UNF

0.30

0.51

0.62

0.62

0.99

0.75

3.1

2.8

3.5

1

0.87

4.92

1.63

4.87

7.25

7.09

3.50

7/16

UNF

0.30

0.51

0.87

0.87

1.98

1.00

3.9

11/2

1.37

5.52

2.22

5.75

8.00

7.87

4.50

9/16

UNF

0.35

0.71

1.37

1.37

1.98

1.50

8.7

7.9

2

1.87

6.46

2.81

6.81

9.75

9.84

5.50

9/16

UNF

0.35

0.71

1.87

1.87

2.51

2.00

13.6

13.0

21/2

2.37

6.02

3.50

7.50

11.00

18.90

6.50

1 UNF

0.75

0.67

2.37

2.37

3.04

2.50

28.7

28.0

3

2.87

6.61

4.27

8.77

12.75

18.90

8.12

1 UNF

0.75

0.67

2.87

2.87

3.58

3.00

50.1

49.3

4

3.83

7.17

5.30

9.80

14.25

18.90

9.25

1 UNF

0.75

0.67

3.384

3.384

4.68

4.00

81.5

80.5

1. Dimensions are for layout purposes only. Contact the factory for exact dimensions.

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

6

MCF True/Tube™

Micro-Clean Ball Valve

Specifications

Pressure and Temperature Ratings

Maintaining maximum pressure ratings up to

1500 psi using Standard PTFE Seats and

Seals is a viable option in MCF Micro-Clean

valves using TBX end pieces.1 Optional seat

and seal configurations include TFM-1600,

UHMWPE, TF-4215 and other materials. In

addition to its bubble tight seat design, a

separate encapsulated seal prevents seal

extrusion and subsequent leaks to atmosphere.

It also eliminates an additional area of potential

contamination from deposits trapped by the

integral seat/seal combinations used in some

other similar valves.

Bars-psig

52-750

48-700

45-650

41-600

105-1520

103-1500

2” to 3”

34-500

4”

100-1450

28-400

95-1378

21-300

90-1306

1/2”

14-200

to 3/4”

7-100

80-1160

11/2”

70-1000

Bars - psig

Note

1. Use of clamp type ends may affect the limits

of pressure ratings.

1/2”

to 11/2”

Legend

60-870

Saturated Steam

“HT” High Temperature

Seat (TF-4215)

“TE” Seat (TFM-1600)

“TF” Seat (PTFE)

11/2”

1/2”

52-750

50-725

to 3/4”

2” to 3”

44-650

4”

45-580

30-435

Flow Data (Cv)

Valve Size

Inches

USGPM

(Cv)*

1/2

14

3/4

44

20-285

15-215

71

10-145

11/2

214

5-72

2

405

21/2

626

1

3

908

4

1,643

32

68

104 140 176 212 248

0 [20] [40] [60] [80] [100] [120]

302

392

470

575

[150]

[200]

[250]

[300]

Temperature, F° [C°]

* (USGMP @1 psig)

Interior Surface Finishes of Valve Components

Valve

Components

Ra Average, µ - in.

V3

V6

V4

Mechanical Polish

Electro-Polish

Body Interior

25

20

10

Ball Interior

25

20

10

TBX End (Interior)

25

20

10

KCE End (Interior)

25

20

10

Setting high standards and tolerances in

both standard and optional wetted

surface finish, MCF Micro-Clean ball

valves are precision machined to reduce

the microscopic peaks and valleys which

harbor deposits that can erode and

subsequently contaminate media.

MCF standards apply to all wetted

machined surfaces.

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

7

MCF True/Tube™

Micro-Clean Ball Valve

Ordering Information

1/2”

T/T

V3

6

6

TF

T

KCE

I

H

---

Size

1/2”

1” 11/2” 3/4”

DN15

DN20

DN25

DN40

2”

21/2”

3”

4”

- DN50

- DN65

- DN80

- DN100

Port

T/T - True-Tube (Port ID of the Valve Matches the ID of the SS OD Tubing)

Internal Surface Finish Designation

Mechanically Polished - Interior Surface Finish per ASME BPE-1997

V3 - 25 Ra

V2 - 20 Ra (Optional - POA)

V1 - 15 Ra (Optional - POA)

Mechanically Polished and Electropolished - Interior Surface Finish per ASME BPE-1997

V6 - 20 Ra

V5 - 15 Ra (Optional - POA)

V4 - 10 Ra (Optional - POA)

Body and Endpieces

6 - Bodies 1/2” to 2” - A182-316L /

DIN 1.4404 SS / 21/2” to 4” - A351-CF8M / DIN 1.4408 316 SS

Ball and Stem

6 - 316L (DIN 1.4404) SS

Seats

TF

TE

HT

UU

LC

-

Virgin PTFE

Reinforced PTFE (TFM-1600 Enhanced PTFE)

TF-4215 Enhanced 25% Carbon Filled PTFE

UHMWPE

TFM-1600 Enhanced PTFE

Body Seals

T

U

H

L

-

Virgin PTFE

UHMWPE

TF-4215 Enhanced 25% Carbon Filled PTFE

TFM-1600 Enhanced PTFE

End Connections

TBX - O.D. Tube (SS) Extended Length For Automatic/Orbital Welding (1/2” to 3” OD Tube WT = 0.065”, 4” OD Tube WT = 0.083”)

KCE - Tri-Clamp Style

Valve Body Style/Design (Standard Feature)

I - ISO 5211 Flange and Bolting Pattern Design

Handle Options

H

O

R

L

G

-

S.S. Lever Handle (except for 21/2” and larger valves, H - C.S. Pipe Lever Handle)

S.S. Oval Handle (For 11/2” and smaller valves)

S.S. Round Handle (For 11/2” and smaller valves)

S.S. Latch Locking Handle (For 2” and smaller valves)

Gear Operator (Recommended for 4” valves)

Accessories/Special Options

--NAP

ES3

ES6

P

CFTF

CFHT

-

TBA - Consult Factory For Ordering Code Suffix Regarding Accessories and Special Options Including

No Anti-static Stem Packing

3 Inch Tall Extended Stem (Same ISO Flange and Stem Pattern as Valve) - 1/2” to 2” Valves

6 Inch Tall Extended Stem (Same ISO Flange and Stem Pattern as Valve) - 1/2” to 4” Valves

SIP (Steam In Place) / CIP (Clean In Place) Purge Port(s) - POA Option, Consult Factory (Not Available in Conjunction with Cavity Fillers)

PTFE Cavity Filler1

Notes

TF-4215 Enhanced Carbon Filled PTFE Cavity Filler1

Facility Phone: 713-744-4596

Facility Fax: 713-744-4594

Valves & Controls

www.tycovalves.com

1. Cavity Filler - POA Option, Consult Factory.

Note: CIP / Purge Ports Provide a Higher

Degree of Cleanliness than Cavity Fillers.

2. Tri-Clamp is a registered trademark of the

Ladish Corp.

The data presented in this bulletin is for general information only. Manufacturer is not responsible for acceptability of these products in relation to system requirements. Patents and Patents

Pending in U.S. and foreign countries. All rights reserved. Printed in U.S.A. Tyco reserves the right to change product design and specifications without notice. © Copyright 2002.

Tyco reserves the right to change product design and specifications

without notice. Copyright © 2002 by Tyco International Ltd.

MCFMC-0284

8