Airmovers Catalogue

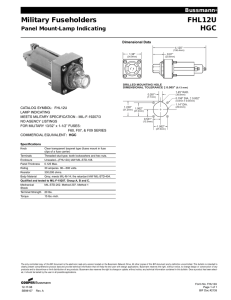

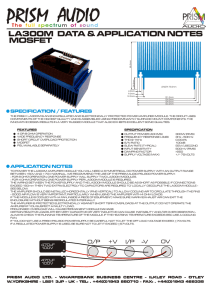

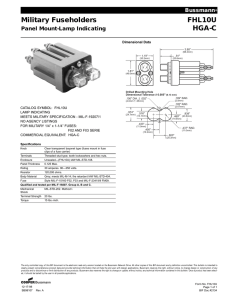

advertisement