A Behavioral Freight Transportation Modeling System

advertisement

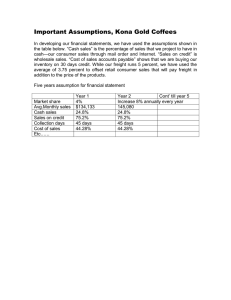

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 A Behavioral Freight Transportation Modeling System Zahra Pourabdollahi Ph.D. Student Department of Civil and Materials Engineering University of Illinois at Chicago 842 W. Taylor Street Chicago, IL 60607-7023 Tel: (312) 996-0962 Email: zpoura2@uic.edu Amir Samimi, Ph.D. Assistant Professor Department of Civil Engineering Sharif University of Technology Azadi Avenue, Tehran, Iran Tel: +98 (21) 6616-4219 Email: asamimi@sharif.edu Abolfazl (Kouros) Mohammadian, Ph.D. Associate Professor Department of Civil and Materials Engineering University of Illinois at Chicago 842 W. Taylor Street Chicago, IL 60607-7023 Tel: (312) 996-9840 Email: kouros@uic.edu Kazuya Kawamura, Ph.D. Associate Professor College of Urban Planning and Public Affairs University of Illinois at Chicago 412 S. Peoria Street Chicago, IL 60607-7064 Tel: (312) 413-1269 Email: kazuya@uic.edu Word Count: 2,162 + (3*250) = 2,912 1 1 1. Introduction 2 Freight movements have significant impacts on transportation system, regional wellbeing and 3 economic growth. Because of the complexity of decision-making in freight system, sophisticated 4 modeling tools are used for forecasting, policy assessment, and counteracting the impacts of 5 freight movements. Unlike the passenger transportation subject, freight transportation is a 6 relatively less-researched field in terms of advanced modeling applications. However, this has 7 been recognized by researchers around the world and the field is rapidly developing in many 8 directions, including data collection, modeling frameworks, and operational strategies. There are 9 still significant gaps in terms of our understanding of the fundamentals and the nature of freight 10 movement systems and their behavioral decision making process. 11 Review of the literature revealed that many available freight transportation models have 12 aggregate nature. Moreover, many of the current models are short in term of logistics elements 13 such as, use of intermediate handling facilities, determining optimum shipment size, mode 14 choice, and multi-modal shipments. Many researchers have discussed the drawbacks of the 15 aggregate models in capturing the complexity of freight policy systems (1 and 2). In particular, 16 they cannot replicate the supply chains and logistics decisions made by individual actors in the 17 freight system. Recently, there have been some advances in developing logistics models at the 18 urban level with a primary focus on road transportation. The urban logistics models are effective 19 analysis tools at the local level. However, a more comprehensive framework and detailed 20 behavioral models are needed to assess policies at the national level and to examine the effects of 21 changes to the system-level elements (e.g., expanding ports capacity, or widening the Panama 22 Canal) on regional/national level freight movement. 23 This paper introduces a behavioral microsimulation framework for freight transportation 24 modeling named FAME (Freight Activity Micro-simulation Estimator). FAME has a wide 25 geographic coverage and to the best of the authors’ knowledge, it is the first comprehensive 26 nationwide freight microsimulation model in the U.S. The FAME model uses a fresh approach in 27 modeling freight demand by incorporating a modular structure and working at the disaggregate 28 level of firm as the basic decision-making unit in the freight market. The large-scale model 29 simulates commodity movements in the U.S. at the disaggregate level of firm-to-firm. Data 2 1 scarcity appears to be a crucial barrier in developing such a disaggregate logistics model. A set 2 of publicly available datasets are utilized to develop the model. In addition, more detailed 3 information concerning individual shipments is collected through an online nationwide 4 establishment survey, conducted by the research team (3). 5 6 2. Freight Activity Micro-simulation Estimator (FAME) 7 FAME was introduced as a freight activity-based modeling framework with five basic 8 modules(4). This paper provides very brief overview of this framework. Interested readers may 9 refer to Samimi et al. (4) for further elaboration of the FAME framework. FIGURE 1 illustrates 10 FAME framework. In the first module, all firms in the study area are synthesized and their basic 11 characteristics, including industry type, employee size, and location are identified. Based on each 12 firm's characteristics, types and amounts of incoming and outgoing goods are determined, and 13 trade relationships are formed for each pair of supplier-buyer firms in the second module. Third 14 and forth modules deal with logistics choices. In the third module, the shipment sizes are defined 15 based on the acquired information on the firms’ characteristics, and shipping modes are 16 determined in the fourth module. Finally, in the last module, the impact of the goods movements 17 on transportation network is investigated. 18 Four categories of data are required for developing FAME: information on business 19 establishments for the first module, aggregate freight flows (OD matrix) for the second module, 20 detailed information on a sample of individual shipments and supply chains for the third and 21 forth tasks, and specifications of the transportation networks for the last module. 22 23 24 3 Firm-type Generation Identifying individual decision-makers Supplier selection Determining relationships between firm-types Logistics decisions Shipment size determining Based on observed shipment size distribution Mode choice Select mode of transportation Network analysis Assigning commodity flows to the traffic network and assess the impacts 1 2 FIGURE 1. FAME OPERATIONAL FRAMEWORK 3 4 Firm-types Generation 5 As discussed earlier, FAME simulates freight flows at the disaggregate level of firm-to-firm. 6 Thus, the decision-makers in this microsimulation are individual firms in the U.S. Since, there 7 are more than 239,000 firms with six digit North American Industry Classification System 8 (NAICS) industry type in the U.S. (5). Some form of aggregation is inevitable to keep the 9 computational burden at a reasonable level and diminish the need for highly disaggregated data. 10 We proposed to aggregate the firms based on firm-types. A firm-type is a collection of firms 11 with similar location, industry type, and establishment size. It is assumed that firms with the 12 same characteristics have the similar behavior in freight decision-making process. Number of 13 firm-types can differ based on the number of industry types, establishment size, and geographic 14 zones in the study area. Considering 123 domestic zones, 328 industry classes (NAICS), and 4 1 eight employee size groups in this simulation, a total of 45,206 firm-types were identified in the 2 U.S. 3 4 Supplier Selection 5 Trade relationships were replicated based on a fuzzy expert system that was developed by the 6 research team (6). This model scores the appropriateness of all the possible suppliers for a given 7 firm-type. Having the likelihood of partnership for any pair of supplier and buyer, annual 8 commodity flows is disaggregated from geographic zone level into firm-type level. For a given 9 origin, destination, and commodity type, the value of total annual tonnage was obtained from 10 Freight Analysis Framework data (FAF3.0) (7) and disaggregated between the top five percent of 11 supplier and buyer pairs with the highest appropriateness score. 12 Two-digit Standard Classification of Transported Goods (SCTG) used in FAF is also 13 utilized in this study to classify the commodities. All FAF industry sectors were considered in 14 FAME, but some of them were not present in specific zones in the simulation. This is due to the 15 limitations of business establishment data sources and also the crosswalks that were used in the 16 second module to connect industries to commodities. As a result, not all of the FAF commodity 17 flows between the zone pairs was allocated to firm-types. In total, freight flows for 40 classes of 18 commodity types is simulated in FAME. 19 20 Shipment Size Determination 21 A shipment size model, developed by the research team (6), provides a categorical output 22 variable with three clusters: small (less than 1,000 lb), medium (1,000-50,000 lb), and large 23 (more than 50,000 lb). Establishment size of the supplier and buyer, shipping distance and 24 commodity type, are the inputs of the model. This model was applied on the annual commodity 25 flow between each pair of supplier and buyer from the former section and determined share of 26 small, medium, and large shipments accordingly. However, knowing that a shipment is small is 27 not enough to run the modal split in the next module and a crisp value should be assigned as 28 well. In order to do so, a distribution of observed shipment sizes from the UIC National Freight 5 1 Survey (3) was obtained for each class of shipment size. Details of the shipment size model and 2 the shipment size distributions are elaborated elsewhere (6). 3 4 Modal Split 5 A binary probit mode choice model was deployed in this simulation to determine the share of 6 truck and rail (including truck-rail intermodal) for each shipment. This model has a proxy for 7 distance, weight, relative impedance between truck and rail, a dummy for containerized 8 shipments and commodity type as input variables all of which have to be determined for every 9 simulated shipment. In this simulation the overall probability of having containerized shipments 10 was assumed to be 11.8%, according to the UIC National Freight Survey (3). Although the 11 binary mode choice has a satisfactory goodness of fit, it underestimates the total number of rail 12 shipments. Therefore, the estimated probability of a rail shipment is increased by a 1.3 factor to 13 cover this underestimation in general. 14 Modal split of domestic freight movements in the U.S. was performed by calibrating and 15 simulating the first four modules of FAME. As mentioned, only truck and rail (including truck- 16 rail intermodal) are covered as the primary modes of freight transportation, and the relative 17 percentages of total tonnage, value, and ton-mile of commodities between the two modes are 18 estimated. Due to the random nature of the microsimulation, the simulation was repeated several 19 times. Although the tonnage of the shipments carried by each mode is obtained directly from the 20 model, the dollar value of the shipment is approximated using FAF3.0 dataset. 21 22 3. Simulation Results 23 Some of the major results of this microsimulation are presented in this section. Since there is no 24 disaggregate freight data available, the results are aggregated and validated with public aggregate 25 datasets. TABLE 1 shows results of the modal split model in FAME. It presents the relative 26 percentages of total tonnage, value, and ton-mile of commodities between two modes simulated 27 in FAME and compares them with FAF3.0 and Commodity Flow Survey (CFS) estimates. It 6 1 should be noted, that modal split information of none of these datasets has been used in model 2 calibration and thus can be an appropriate base line for validation. 3 4 TABLE 1. MODAL SPLIT VALIDATION IN FAME Item Tonnage Value Ton-mile Rail Truck Rail Truck Rail Truck CFS 2007 FAF3.0 FAME 19% 81% 7% 93% 53% 47% 16% 84% 18% 82% 48% 52% 16% 84% 18% 82% 48% 52% 5 6 Moreover, FIGURE 2 compares simulated commodity flows in FAME with FAF estimates 7 by commodity type. Based on FAF dataset, a total of 14,845 million tons of commodities valued 8 at around 12,276 billion dollars is transported between the domestic origin and destinations on 9 truck, rail, or truck-rail intermodal (7). In total, 14,202 million tons of commodities valued at 10 around 10,916 billion dollars is simulated in FAME. Thus, more than 95% of FAF domestic 11 tonnage and around 89% of commodity values is simulated in this study. FIGURE 2 shows the 12 result of second module (supplier selection) where trade relationships are formed and commodity 13 flows are simulated between firm-types. 14 Cereal grains Other ag prods. Animal feed Meat/seafood Milled grain prods. Other foodstuffs Alcoholic beverages Tobacco prods. Building stone Natural sands Gravel Nonmetallic minerals Metallic ores Coal Crude petroleum Gasoline Fuel oils Coal-n.e.c. Basic chemicals Pharmaceuticals Fertilizers Chemical prods. Plastics/rubber Logs Wood prods. Newsprint/paper Paper articles Printed prods. Textiles/leather Nonmetal min. prods. Base metals Articles-base metal Machinery Electronics Motorized vehicles Transport equip. Precision instruments Furniture Misc. mfg. prods. Waste/scrap 2,500,000 1 2 2,250,000 FAF (KTon) 2,000,000 FAME (KTon) 1,750,000 1,500,000 1,250,000 1,000,000 750,000 500,000 250,000 0 FIGURE 2: COMMODITY FLOWS (KTON) (COMPARISON BETWEEN FAME AND FAF) 1 1 4. CONCLUSION 2 The primary motivation for this research was to develop a behavioral freight transportation 3 model in the U.S. Therefore, a nationwide freight activity microsimulation was conducted. A 4 major drawback of many previous studies of this kind is the aggregate nature which prevents the 5 development of an actor-based microsimulation. A large-scale behavioral microsimulation 6 framework, named FAME was developed in this study. This framework incorporates firms’ 7 characteristics in replicating shipping behaviors, and aimed at paving the way for future 8 behavioral freight microsimulation efforts. Final results of simulation showed a close match with 9 CFS 2007, and FAF3.0 data. This study aimed at facilitating a sound microsimulation freight 10 model as a valid forecast tool that eventually could contribute to more reliable policy 11 assessments compared to currently available decision tools. 12 FAME is largely based on public freight data in the U.S. and therefore data collection costs 13 are substantially mitigated. Furthermore, this study covered a wide range of industry classes and 14 commodity types. FAME has a unique geographic coverage, as well, and to the best of the 15 authors’ knowledge, it is the first comprehensive nationwide freight microsimulation in the U.S. 16 This study presented the first steps toward a comprehensive activity-based freight 17 microsimulation. There are still several components that need further exploration. 18 19 ACKNOWLEDGMENTS 20 This work was (partially) funded by the National Center for Freight and Infrastructure Research 21 and Education (CFIRE) based at the University of Wisconsin. CFIRE is a national university 22 transportation center supported by the US Department of Transportation. Partial funding was 23 also provided by Illinois Department of Transportation (IDOT). All responsibility for the 24 contents of the paper lies with the authors. 25 26 2 1 REFERENCES 2 1. Chow, J.Y.J, C.H. Yang, and A.C. Regan. State-of-the Art of Freight Forecast Modeling: 3 Lessons Learned and The Road Ahead, Transportation 37(6), pp. 1011–1030, 2010. 4 2. Regan, A.C., and R.A. Garrido Modeling freight demand and shipper behavior: state of the 5 art, future directions. In: D. Hensher, Editor, Travel Behavior Research: The Leading Edge, 6 Pergamon, Amsterdam, pp. 1–30, 2001. 7 3. Samimi, A., A. Mohammadian, K. Kawamura, “An Online Freight Shipment Survey in the 8 United States: Lessons Learned and Nonresponse Bias Analysis”, Proceedings of the 89th 9 Annual Meeting of the Transportation Research Board (DVD), Washington, D.C., January 10 11-15, 2010. 11 4. Samimi, A., A. Mohammadian, and K. Kawamura. A behavioral freight movement 12 microsimulation model: method and data. Transportation Letters: The International Journal 13 of Transportation Research, pp. 53-62, 2010. 14 5. U.S. Census Bureau: Economic Planning and Coordination Division. County Business 15 Patterns. Available at: http://www.census.gov/econ/cbp/download/index.htm, accessed 16 February 2011. 17 6. Samimi, A., A Behavioral Mode Choice Microsimulation Model for Freight Transportation 18 in the U.S. PhD Dissertation, College of Engineering, University of Illinois at Chicago, 2010. 19 7. Federal Highway Administration. The Freight Analysis Framework, Version 3: Overview of 20 FAF3 National Freight Flow Tables, 2010.