strain"gage"may"be"

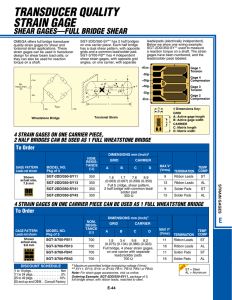

advertisement