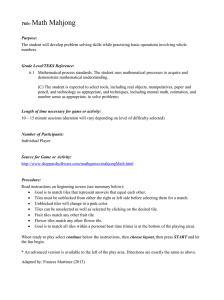

From intuitive parameters to the requirements that

advertisement