International Journal of Refrigeration 30 (2007) 1153e1167

www.elsevier.com/locate/ijrefrig

Airside heat transfer and friction characteristics

for enhanced fin-and-tube heat exchanger with

hydrophilic coating under wet conditions

Xiaokui Maa, Guoliang Dinga,*, Yuanming Zhanga, Kaijian Wangb

b

a

Institute of Refrigeration and Cryogenics, Shanghai Jiaotong University, 1954 Huashan Road, Shanghai 200030, China

Fujitsu General Institute of Air-Conditioning Technology Limited, 1116 Suenaga, Takatsu-Ku, Kawasaki 213-8502, Japan

Received 8 November 2006; received in revised form 21 January 2007; accepted 1 March 2007

Available online 12 March 2007

Abstract

The airside heat transfer and friction characteristics of 14 enhanced fin-and-tube heat exchangers with hydrophilic coating

under wet conditions are experimented. The effects of number of tube rows, fin pitch and inlet relative humidity on airside performance are analyzed. The test results show that the influences of the fin pitch and the number of tube rows on the friction

characteristic under wet conditions are similar to that under dry surface owing to the existence of the hydrophilic coating.

The Colburn j factors decrease as the fin pitch and the number of tube rows increase. For wavy fin, the Colburn j factors increase

with the increase of the inlet relative humidity, but for interrupted fin, the Colburn j factors are relatively insensitive to the

change of the inlet relative humidity. The friction characteristic is independent of the inlet relative humidity. Based on the

test results, heat transfer and friction correlations, in terms of the Colburn j factor and Fanning f factor, are proposed to describe

the airside performance of the enhanced fin geometry with hydrophilic coating under wet conditions. For wavy fin, the correlation of the Colburn j factor gives a mean deviation of 7.6%, while the correlation of Fanning f factor shows a mean deviation of

9.1%. For interrupted fin, the correlation of the Colburn j factor gives a mean deviation of 9.7%, while the correlation of Fanning

f factor shows a mean deviation of 7.3%.

Ó 2007 Elsevier Ltd and IIR. All rights reserved.

Keywords: Heat exchanger; Cooler; Humid air; Finned tube; Enhanced surface; Heat transfer; Coefficient; Friction; Coating

Transfert de chaleur côté air et caractéristiques de frottement

d’un échangeur à tubes ailetés muni d’un enrobage

hydrophile sous des conditions mouillées

Mots clés : Échangeur de chaleur ; Refroidisseur d’air ; Air humide ; Tube aileté ; Surface augmentée ; Transfert de chaleur ; Coefficient ;

Frottement ; Revêtement

* Corresponding author. Tel.: þ86 21 62932110; fax: þ86 21 62932601.

E-mail address: glding@sjtu.edu.cn (G. Ding).

0140-7007/$35.00 Ó 2007 Elsevier Ltd and IIR. All rights reserved.

doi:10.1016/j.ijrefrig.2007.03.001

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1154

Nomenclature

a

A1

A2

Afr

Amin

A0

b

Cp

Dc

f

Fp

Fs

Gc

hm

hs

i

ifg

I0

I1

j

k

K0

K1

Le

m

m*

Mfb

M*

N

Pl

Pr

Pt

coefficient defined by Eq. (14)

outside surface area of tubes (m2)

surface area of fin (m2)

frontal area (m2)

minimum free-flow area (m2)

total airside surface area (m2)

coefficient defined by Eq. (14)

specific heat (J kg1 K1)

fin collar outside diameter (mm)

friction factor

fin pitch (mm)

fin spacing (mm)

mass flux of the air based on the minimum flow

area (kg m2 s1)

mass transfer coefficient (kg m2 s1)

sensible heat transfer coefficient (W m2 K1)

enthalpy (J kg1)

saturated water vapor enthalpy (J kg1)

modified Bessel function solution of the first

kind, order 0

modified Bessel function solution of the first

kind, order 1

the Colburn factor

thermal conductivity (W m1 K1)

modified Bessel function solution of the second

kind, order 0

modified Bessel function solution of the second

kind, order 1

Lewis number

mass flow rate (kg s1)

coefficient defined by Eq. (22)

coefficient defined by Eq. (10)

coefficient defined by Eq. (9)

number of longitudinal tube rows

longitudinal tube pitch (mm)

Prandtl number

transverse tube pitch (mm)

1. Introduction

Enhanced fins including wavy fin and interrupted fin

are widely used to improve the performance of fin-andtube heat exchangers. The wavy fin enhances heat transfer

by lengthening the air flow channel and causing better

mixing of air flow. The interrupted fin, including louver

fin and slit fin, enhances heat transfer by renewing the

boundary layer and reducing the thickness of the boundary

layer. In practical application of fin-and-tube heat exchangers, condensation phenomena will occur on the fin

surface when the surface temperature is below the dew

point temperature of incoming air. The presence of condensate water makes the heat/mass transfer process more

DP

Q

Qs

Ql

r

ReDc

RH

T

Ta*

V

W

pressure drop of airside (Pa)

average heat transfer rate (W)

sensible heat transfer rate (W)

latent heat transfer rate (W)

fin radius (m)

Reynolds number based on tube collar diameter

relative humidity

temperature ( C)

coefficient defined by Eq. (11)

velocity (m s1)

humidity ratio of moist air (kg kg1)

Greek symbols

b

coefficient defined by Eq. (12)

d

fin thickness (mm)

hf,wet

wet fin efficiency

ho

overall surface effectiveness

x

boundary line between dry region and wet

region

ri

inlet air density (kg m3)

rm

mean air density (kg m3)

ro

outlet air density (kg m3)

s

contraction ratio of the fin array

Subscripts

a

air

d

dew point

dry

dry bulb temperature

f

fin

fb

fin base

ft

fin tip

i

inner

in

inlet

o

outer

out

outlet

s

saturated

w

water

complicated. In recent years, airside performance research

of enhanced fin-and-tube heat exchangers in wet conditions was performed gradually. Mirth and Ramadhyani

[1,2] presented test results for five smooth wavy fin patterns. Their results showed that the Nusselt numbers are

very sensitive to the change of inlet air dew point temperature, and the Nusselt numbers decrease with the increase

of inlet air dew point temperature. Wang et al. [3e5] analyzed the effects of the number of tube rows, the fin pitch

and tube size etc. on airside performance for herringbone

wavy fin patterns in wet conditions, and developed the airside heat transfer and friction correlations. For slit fin,

only Wang et al. [6] presented test results for three slit

fin-and-tube heat exchangers under wet conditions. The

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

Until now, there is no research on the enhanced finand-tube heat exchangers with hydrophilic coating under

wet conditions. As a consequence, the objective of the present study is to study the effects of the fin pitch, the number of

tube rows and the inlet relative humidity on the airside heat

transfer and friction characteristics for the enhanced fin with

hydrophilic coating under wet conditions with experimental

method, and develop heat transfer and friction correlations,

in terms of the Colburn j factor and Fanning f factor, based

on the test results.

effects of the number of tube rows, the fin pitch and the

inlet relative humidity on airside performance were reported, and the heat transfer and friction correlation

were developed. For louver fin, Wang et al. [7] and Kim

et al. [8e10] did experimental research relating to airside

performance under wet conditions. The test results indicated that the effect of the number of tube rows and the

fin pitch on the heat transfer performance is comparatively

small, while the friction factors increase significantly with

the fin pitch for fully wet conditions. The effect of the inlet relative humidity on the sensible heat transfer performance is negligible, and there is detectable effect of the

inlet humidity on the friction factors. The above researches are focused on the fully wet conditions. In practice, partially wet conditions will happen if the fin tip

temperature is higher than the dew point temperature

whereas the fin base temperature is lower than the dew

point temperature. There are a number of papers addressing the heat transfer performance of the heat exchangers

under partially wet surface conditions [11e14], but most of

them are academic research, relative experimental research

is limited.

The above-mentioned researches are focused on the enhanced fin without hydrophilic coating. The condensate

water may adhere as droplets on the fin surfaces without

hydrophilic coating, and this phenomenon will cause bridging between the fins and increasing air pressure drop. Furthermore, the condensate water may corrode aluminum fins, and

produce corrosion problems. A solution to solve this problem

is to add hydrophilic coating on the aluminum fins. The hydrophilic coating can effectively improve the condensate

drainage and decrease airside pressure drop [15,16]. The airside performance is different between fin-and-tube heat exchangers with hydrophilic coating and fin-and-tube heat

exchangers without hydrophilic coating [17,18], and the hydrophilic coating has been applied on the fin surface widely,

so it is necessary to study the airside performance of enhanced fin with hydrophilic coating under wet conditions.

7

4

8

6

5

13

9

10

12

11

13

14

15

2. Experimental apparatus

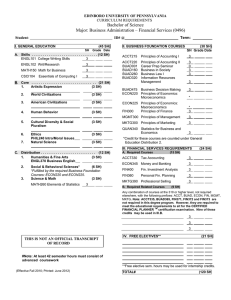

The experimental apparatus is schematically illustrated

in Fig. 1, which includes an air flow loop, a water flow

loop, a data acquisition system and the test heat exchangers.

A closed type wind tunnel is used to conduct the air

flow through the heat exchanger. The air duct is made

of galvanized steel sheet and the test section has

a 210 mm 210 mm cross-section. A variable speed centrifugal fan (0.75 kW) is used to circulate the air, which passes

through nozzle chamber, air conditioner box, mixing device,

straightener, and test heat exchanger orderly. The air flow

rate measurement is detected by multiple nozzles based on

the ASHRAE 41.2 standard [19]. A differential pressure

transducer with 5.0 Pa precision is used to measure the

pressure difference across the nozzles. A pressure transducer

with 1.0 kPa precision and a dry bulb and wet bulb temperature transducer with 0.3 C precision are used to measure

the inlet air conditions of nozzles. The air conditioner box is

used to control the temperature and humidity of inlet air,

which are allowed 0.2 C and 3% fluctuation range.

The test section is insulated with a 15 mm thick standard

sheet. A differential pressure transducer with 0.2 Pa precision is used to measure the pressure difference across the

heat exchangers. The dry bulb temperature and relative

humidity of the inlet and outlet air are measured by two temperature and humidity transducers with 0.1 C and 1.4%

2

1

16

1155

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Volume flow meter

Pump

Thermostat

Air conditioner box

Mixer

Straightener

Temperature and humidify transducer

Fin-and-tube heat exchanger

Video camera

Pressure difference transducer

Pressure difference transducer

Pressure transducer

Straightener

Nozzle

Dry and wet bulb temperature meter

Variable speed centrifugal fan

Fig. 1. Schematic of experimental setup.

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1156

precision. Six K-type thermocouples with 0.1 C precision

welded on the tube surface are used to measure the fin base

temperature.

Water flow loop consist of a thermostat, a centrifugal

pump and a magnetic flow meter with 0.15 L/min precision. The purpose of this loop is to provide the cool capacity

of the test heat exchangers. After the water reaches the required temperature, it is pumped out from the thermostat,

delivered to the heat exchanger and then returned to the thermostat. The water temperature difference between inlet and

outlet of heat exchangers is measured by two K-type thermocouples with a calibrated accuracy of 0.1 C. All signals

are registered by a data acquisition system and finally averaged over the elapsed time.

Fourteen fin-and-tube heat exchangers for testing are

made of aluminum fin and copper tube. Detailed dimensions

of the heat exchangers and the enhanced fins are shown in

Figs. 2 and 3, respectively. Their detailed configurations are

tabulated in Table 1. Fin surface coatings including anticorrosive layer and hydrophilic coating are shown in Fig. 4.

The coating material is organic resin, the thickness of anticorrosive layer and hydrophilic coating is 1.1 mm and 0.8 mm,

and the water contact angle of hydrophilic coating surface is

10e20 initially. Coating process chart is shown in Fig. 5.

Condensation phenomena on the fin surface are recorded

by a video camera put at the outlet of air. Totally, 23 test conditions are listed in Table 2. The experimental rig’s repetition quality as well as the influence of the camera on the

airside pressure drop measurement was tested with the No.

1 heat exchanger in Table 1 under No. 5 and No. 10 test conditions in Table 2. Experimental rig’s repetition quality data

are listed in Table 3. The maximum repetition error of heat

transfer capacity is 2.1%, and the maximum repetition error

of airside pressure drop is 1.1%. Experimental rig’s repetition quality is fine. The influence of the camera on the airside

pressure drop measurement is shown in Table 4, the existence of the camera changes the pressure loss of air flow

through heat exchangers by less than 1.1%, and the influence

of the camera can be omitted in the following study. Experimental uncertainties are reported according to the analysis

method proposed by Moffat [20], and the maximum error

of the Colburn j factor and Fanning f factor are 10.2%

and 9.4%, respectively. The detailed analysis results are

tabulated in Table 5.

3. Data reduction

3.1. Airside sensible heat transfer coefficient hs

Under wet conditions, the heat transfer rate of test heat

exchangers Q includes sensible heat transfer rate Qs and

latent heat transfer rate Ql, namely,

h i

ð1Þ

Q ¼ Qs þ Ql ¼ ho A0 hs Ta Tfb þ hm ifg Wa Wfb

The ho in Eq. (1) is the overall surface efficiency, and is

related to the fin surface area, total surface area, and wet

fin efficiency:

ho ¼ A1 þ hf;wet A2 A0

ð2Þ

The heat transfer and mass transfer coefficients are correlated

by the ChiltoneColburn analogy [21], which is expressed as

hs

¼ Cp;a Le2=3

hm

ð3Þ

From Eqs. (1)e(3), the airside sensible heat transfer coefficient hs can be gotten,

hs ¼ A1 þ hf;wet A2

h

Q

i

ifg

Ta Tfb þ Cp;a Le

2=3 Wa Wfb

ð4Þ

3.2. Heat transfer rate Q

The total heat transfer capacity Q used in Eq. (4) is averaged from the airside and the waterside as follows:

Q ¼ ðQa þ Qw Þ=2

ð5Þ

where

Qa ¼ ma ðia;in ia;out Þ

ð6Þ

Water Inlet

Water Outlet

Base Temperature Measurement

Unit: mm

Fig. 2. Structure dimensions of the tested fin-and-tube heat exchangers.

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1157

(a)

1.393

16.3º

9.525

Air flow direction: From reader into the paper

(b)

A

Air flow

direction

A

DETAIL A-A

(c)

A

Air flow

direction

A

DETAIL A-A

Unit: mm

Fig. 3. Structure dimensions of the test enhanced fin patterns (a) wavy fin, (b) slit fin, and (c) louver fin.

Qw ¼ mw Cp;w ðTw;out Tw;in Þ

ð7Þ

In the experiments, only those data that satisfy the ASHRAE

standard [22] requirements (namely, the energy balance conditions, jQw Qj=Q 0:05) are considered in the final analysis.

3.3. Wet fin efficiency hf,wet

For fin-and-tube heat exchanger, the wet fin efficiency

hf,wet is normally calculated by the equivalent circular area

method. McQuiston and Parker [23] extended the analysis

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1158

Table 1

Geometric dimension of the enhanced fin-and-tube heat exchangers

No. Fp (mm) d (mm) Dc (mm) Pt (mm) Pl (mm) N Interrupted

type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1.2

1.5

1.7

1.4

1.8

1.5

1.4

1.2

1.5

1.7

1.5

1.4

1.8

1.4

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

0.105

7.21

7.21

7.21

9.74

9.74

7.21

9.74

7.21

7.21

7.21

7.21

9.74

9.74

9.74

21.0

21.0

21.0

25.4

25.4

21.0

25.4

21.0

21.0

21.0

21.0

25.4

25.4

25.4

19.05

19.05

19.05

19.05

19.05

19.05

19.05

13.3

13.3

13.3

13.3

19.05

19.05

19.05

2

2

2

2

2

3

3

2

2

2

3

2

2

3

Wavy fin

Wavy fin

Wavy fin

Wavy fin

Wavy fin

Wavy fin

Wavy fin

Slit fin

Slit fin

Slit fin

Slit fin

Louver fin

Louver fin

Louver fin

to circular fins using the approximation proposed by

Schmidt [24]. The wet fin efficiency is given as

tanhðMm ri qÞ

Mm ri q

ð8Þ

2hs

Cifg

1þ

kf df

Cp

ð9Þ

hf;wet ¼

where

Mm2 ¼

q¼

ro

ro

1 1 þ 0:35 ln

ri

ri

ð10Þ

Wa Wfb

Ta Tfb

ð11Þ

Following the approximation (Eq. (11)) proposed by

McQuiston [25], Hong and Webb [26] derived the analytical

formulation of wet surface for circular fins as

hf;wet ¼

where

2hs

ð1 þ abÞ

kf df

ð14Þ

2hs

ð1 þ bCÞ

kf df

ð15Þ

M 2 ¼

2

¼

Mfb

Ta þ bWa bb

1 þ ab

ifg

b ¼ 2=3

Le Cp;a

Ta ¼

2ri

ro2 ri2

Mm

K1 ðMm ro ÞI1 ðMm ri Þ I1 ðMm ro ÞK1 ðMm ri Þ

K1 ðMm ro ÞI0 ðMm ri Þ þ K0 ðMm ri ÞI1 ðMm ro Þ

ð12Þ

ð16Þ

ð17Þ

In the calculation, coefficients a, b and the fin tip temperature Tft need to be iterated. Tft can be calculated by

Eq. (18). If the fin is totally wet (Tft Ta,d), the values of

a and b can be readily determined with Eqs. (19) and (20).

If the fin is partially wet (Tfb Ta,d Tft), the values of

a and b can be determined according to Tfb and Ta,d.

Tf ¼ Ta þ Tfb Ta

K1 ðM ro ÞI0 ðM rÞ þ I1 ðM ro ÞK0 ðM rÞ

ð18Þ

K0 ðM ri ÞI1 ðM ro Þ þ K1 ðM ro ÞI0 ðM ri Þ

Ws;f ¼ aTf þ b

and the constant C in Eq. (9) is given by

C¼

In fact, the parameter C defined by Eq. (11) is not constant, it varies over the fin surface. So Liang et al. [27] developed the wet fin efficiency analytical model as follows:

2ri M Ta Tfb

hf;wet ¼ 2 2

Mfb ro ri2 Ta Tfb

K1 ðM ro ÞI1 ðM ri Þ I1 ðM ro ÞK1 ðM ri Þ

ð13Þ

K1 ðM ro ÞI0 ðM ri Þ þ K0 ðM ri ÞI1 ðM ro Þ

ð19Þ

Ws;f ¼ 3:7444 þ 0:3078Tf þ 0:0046Tf2 þ 0:0004Tf3

103 ; 0 Tf 30 C

ð20Þ

Liang et al. [27] concluded that the above wet fin efficiency

analysis model is suitable for fully wet conditions, but for

partially wet conditions, the above model will bring bigger

error. So we use Liang et al. analytical model [27] to calculate wet fin efficiency for fully wet conditions, and the wet

fin efficiency analytical model for partially wet conditions

is developed in this paper. It should be noted that Liang

et al. [27] did not consider the absolute value for actual

Hydrophilic layer

Anti-corrosive layer

Fin

Anti-corrosive layer

Hydrophilic layer

Fig. 4. Coating structure of fin surface.

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1159

Fig. 5. Coating process of fin surface.

heat transfer rate of fin, a minus value will be gotten if we

use Eq. (13) to calculate the wet fin efficiency, a modified

Equation of Eq. (13) will be used in the final calculation.

The modified equation is given as

2ri M Tfb Ta

hf;h;fullywet ¼ 2 2

Mfb ro ri2 Ta Tfb

K1 ðM ro ÞI1 ðM ri Þ I1 ðM ro ÞK1 ðM ri Þ

ð21Þ

K1 ðM ro ÞI0 ðM ri Þ þ K0 ðM ri ÞI1 ðM ro Þ

There are two conditions under wet conditions. One is fully

wet condition; the other is partially wet condition. First, the

Table 2

The test conditions of experiment

wet fin efficiency is calculated according to the method of

fully wet conditions, but when the fin tip temperature is

larger than the dew point temperature, the partially wet conditions happen, then the wet fin efficiency is calculated

according to the method of partially wet conditions.

For partially wet conditions, the fin base temperature is

lower but the fin tip temperature is higher than the dew point

of air. On the fin surface there is a place, r ¼ x, where the surface temperature equals the dew point of the air. The fin is

then separated into two regions: a wet region (ri r < x)

and a dry region (x r < ro).

For dry region

d2 Tf 1 d2 Tf

þ

þ m2 Ta Tf ¼ 0; x r ro

dr2 r dr 2

1

ð22Þ

No.

Ta,in ( C)

RHin (%)

V (m s )

Tw,in ( C)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

20

20

20

27

27

27

27

27

27

27

27

27

35

35

35

35

35

27

27

27

27

27

27

50

50

50

50

60

70

80

50

50

50

50

50

50

50

50

50

50

60

70

80

60

70

80

0.5

1.0

2.0

1.0

1.0

1.0

1.0

0.5

1.0

2.0

3.0

4.0

0.5

1.0

2.0

3.0

4.0

1.0

1.0

1.0

1.0

1.0

1.0

6

6

6

6

6

6

6

12

12

12

12

12

12

12

12

12

12

12

12

12

18

18

18

The boundary conditions for fin temperature are as

follows:

8

>

< Tf r¼x ¼ Tdew

vTf

ð23Þ

>

¼0

: vr

r¼ro

Then,

Tf ¼ Ta þ ðTdew Ta Þ

K1 ðm ro ÞI0 ðm rÞ þ I1 ðm ro ÞK0 ðm rÞ

K0 ðm xÞI1 ðm ro Þ þ K1 ðm ro ÞI0 ðm xÞ

ð24Þ

For wet region

d2 Tf 1 dTf

þ M 2 Ta Tf ¼ 0; ri r x

þ

dr2 r dr

ð25Þ

The boundary conditions for fin temperature are:

(

Tf r¼ri ¼ Tfb

Tf r¼x ¼ Tdew

ð26Þ

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1160

Table 3

The experimental rig’s repetition quality experiment

No. 5

First

Second

Third

Table 5

Summary of estimated uncertainties

No. 10

Parameter Uncertainty

Heat transfer

capacity (W)

Pressure

drop (Pa)

Heat transfer

capacity (W)

Pressure

drop (Pa)

1709

1731

1722

17.7

17.9

17.7

1380

1363

1351

48.2

48.6

48.5

Using the boundary conditions (26), the analytical solution

of Eq. (25) can be expressed as

I0 ðM rÞK0 ðM xÞ I0 ðM xÞK0 ðM rÞ

Tf ¼ Ta þ

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

Tfb Ta

I0 ðM ri ÞK0 ðM rÞ I0 ðM rÞK0 ðM ri Þ þ

Tdew Ta

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

0.9

1.5

1.8

2.5

ma

mw

Qa

Qw

I1 ðM ri ÞK0 ðM xÞ þ I0 ðM xÞK1 ðM ri Þ

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

Tfb Ta

I0 ðM ri ÞK1 ðM ri Þ þ I1 ðM ri ÞK0 ðM ri Þ

M

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

Tdew Ta

ð28Þ

r¼ri

The fin efficiency is defined as the ratio of the actual fin heat

transfer rate over the maximum possible heat transfer rate if

the entire fin were at the base temperature. Hence,

6.0

0.1

6.9

3.7

8.4

4.0

10.2

9.4

2

Mfb

ro2

The parameter x in Eq. (30) can be determined from the

continuity of heat flow at the point separating the dry and

wet surfaces.

dTf

dr

¼

r¼x

dTf

dr

ð31Þ

r¼xþ

The fin surface temperature distribution at dry region and

wet region in Eq. (31) can be seen as follows.

For wet region

dTf

dr

qact

hf;partiallywet ¼

qmax

hs

DP

j

f

2ri M ri2 Ta Tfb

I1 ðM ri ÞK0 ðM xÞ þ I0 ðM xÞK1 ðM ri Þ

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

Tfb Ta

I0 ðM ri ÞK1 ðM ri Þ þ I1 ðM ri ÞK0 ðM ri Þ

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

ð30Þ

Tdew Ta

hf;h;partiallywet ¼

Then,

¼ M

1.8

2.5

3.9

5.0

Min. (%) Max. (%)

Substituting Eq. (27) into Eq. (29), the partially wet fin

efficiency can be obtained as

ð27Þ

dTf

dr

Parameter Uncertainty

Min. (%) Max. (%)

I1 ðM xÞK0 ðM xÞ þ I0 ðM xÞK1 ðM xÞ

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

Tfb Ta

I0 ðM ri ÞK1 ðM xÞ þ I1 ðM xÞK0 ðM ri Þ

M

I0 ðM ri ÞK0 ðM xÞ I0 ðM xÞK0 ðM ri Þ

Tdew Ta

ð32Þ

¼ M

r¼x

dTf

2pri df kf

dr r¼ri

¼ 2

2p ro ri2 hs Ta Tfb þ b Wa Ws;fb

ð29Þ

For dry region

Table 4

The influence experiment of camera on airside pressure drop

No. 5

First

Second

Third

dTf

dr

¼ ðTdew Ta Þm

r¼xþ

Without

camera

With

camera

Without

camera

With

camera

17.7

17.7

17.6

17.7

17.9

17.7

48.0

48.2

48.3

48.2

48.6

48.5

K1 ðm ro ÞI1 ðm xÞ I1 ðm ro ÞK1 ðm xÞ

K0 ðm xÞI1 ðm ro Þ þ K1 ðm ro ÞI0 ðm xÞ

No. 10

ð33Þ

where

m 2 ¼

2hs

kf df

ð34Þ

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

3.4. Colburn j factor and Fanning f factor

The heat transfer performance is correlated in terms of

the Colburn j factor, i.e.,

j¼

hs

Pr 2=3

Gc Cp;a

ð35Þ

The reduction of the Fanning f factor of the heat exchanger is

evaluated from the pressure drop equation proposed by Kays

and London [28],

ri

Amin rm 2DPri 2

f¼

1

þ

s

1

ð36Þ

A0 ri G2c

ro

where

Amin

Afr

ma

Gc ¼

Amin

s¼

ð37Þ

ð38Þ

4. Results and discussion

Fig. 6 shows the fin efficiency with air inlet relative humidity predicted by the present model, Liang et al. analytical model [27], McQuiston and Parker model [23] and

Hong and Webb model [26]. The calculation of dry fin

efficiency uses Elmahdy and Biggs model [29]. Fig. 6

shows that for a given inlet air dry bulb temperature and

fin base temperature, the fin may work in dry condition,

partially wet condition and fully wet condition depending

1161

on the air inlet relative humidity. For a partially wet fin,

the fin efficiency decreases rapidly with the increase in

air inlet relative humidity. For a fully wet fin, the effect

of the air inlet relative humidity on the fin efficiency is

small. Comparison of the various models shows that the results of McQuiston and Parker model [23] and Hong and

Webb model [26] are significantly different from those of

present model and Liang et al. analytical model [27]. The

wet fin efficiency predicted by McQuiston and Parker

model [23] and Hong and Webb model [26] decreases approximately linearly with the increase of air inlet relative

humidity. These two models fail to distinguish the difference between a partially wet condition and fully wet condition, thus giving a much higher fin efficiency for

a partially wet fin. In these two models, a constant value

of C is assumed based on the conditions at the fin base.

In fact, the parameter C is not constant; it varies over the

fin surface. At a high air relative humidity, this method

underpredicts the fin efficiency due to the use of an unreasonably big C value at this condition. Comparison also

shows that the fin efficiency calculated by Hong and

Webb model [26] is bigger over 10% than the fin efficiency

calculated by McQuiston and Parker model [23], Hong and

Webb [26] indicated that the empirical approximation of

Schmidt [24] used in McQuiston and Parker model [23]

will bring errors. Fig. 6 also shows that analytical model

of Liang et al. [27] is unsuitable for the calculation of

fin efficiency for partially wet condition. Liang et al.

[27] also arrived at similar conclusion by comparing the

analysis model with numerical model for partially wet

condition.

Fig. 6. Comparison of fin efficiencies for a typical case.

1162

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

Fig. 7. Effect of the number of tube rows on the airside performance: (a) wavy fin and (b) interrupted fin.

Fig. 7 shows the effect of the number of tube rows on the

airside heat transfer and friction characteristics of enhanced

fin. The ordinates are Colburn j factors and Fanning f factors,

and the abscissa is the Reynolds number based on collar

diameter. The inlet relative humidity is 50% and the inlet

water temperature is 12 C. As shown in Fig. 7, the Colburn

j factors decrease with the increase of the number of tube

rows. This phenomenon is especially pronounced in low

Reynolds number region. The trend is similar to the results

of plain fin and wavy fin by Wang et al. [3,30]. The possible

explanations of this phenomenon are summarized as

follows. The downstream turbulence is deteriorated by the

vortices formed behind the tube row, and the downstream

turbulence tends to diminish with the increase of the number

of tube rows. When the Reynolds number decreases, the vortices behind the tube become more pronounced [31]. Fig. 7

also indicates that the friction factors are insensitive to the

number of tube rows for wavy fin. Because the condensate

water can be drained by the hydrophilic coating in time,

this phenomenon is very similar to plain fin-and-tube heat

exchanger under dry conditions as shown by Rich [32].

But for interrupted fin, the friction factors decrease slightly

Fig. 8. Effect of the fin pitch on the airside performance: (a) wavy fin and (b) interrupted fin.

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1163

Fig. 9. Effect of the inlet relative humidity on the airside performance: (a) wavy fin, (b) slit fin and (c) louver fin.

with the increase of the number of tube rows. Possible explanations of the effect of the number of tube rows on the friction characteristics are summarized as follows. The structure

of interrupted fin is different with wavy fin, and the interrupted fin is easier to catch the condensate water drop than wavy

fin. As pointed out by the flow visualization experiments

conducted by Yoshii et al. [33] who tested a scale-up model

under wet conditions, when the fin pitch is close to each

other, the droplets adhering to the fin surface may cause

the air flow twisting. As humid air flows across the wet coils,

the corresponding specific humidity decreases along the direction of the air flow, the local dew point temperatures also

decrease and the driving potential of mass transfer also decreases. The condensate water rate and twisted air flow

may decrease as the number of tube rows increase. As a result, the friction factors decrease with the increase of the

number of tube rows.

Fig. 8 depicts the effect of fin pitch on the airside performance of heat exchangers having a 2-row configuration.

The tested fin pitches are 1.2, 1.4, 1.5, 1.7 and 1.8 mm,

respectively. The Colburn j factors decrease with the

increase of the fin pitch. Partially wet conditions will

happen with the increase of Reynolds number, and thus

phenomenon becomes more pronounced under partially

1164

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

Fig. 10. Condensation photos of fin-and-tube heat exchanger

(Fp ¼ 1.5 mm, Ta,dry ¼ 27 C, Va,in ¼ 1.0 m/s).

wet conditions. For wavy fin, the Colburn j factors for

Fp ¼ 1.2 mm which is about 10e20% higher than that

for Fp ¼ 1.7 mm. The causes of this result are summarized

as follows. When the fin pitch decreases, the air flow inside the wavy flow channel can be mixed better, which

leads to the increase of the heat transfer coefficient. The

mixing effect is amplified with the increase of Reynolds

number. For interrupted fin, the results are quite different

from the corresponding test results of interrupted fin without hydrophilic coating as reported by Wang et al. [17,18],

who found that the heat transfer performance is relatively

insensitive to change of fin pitch. A possible explanation

for the effect of fin pitch without hydrophilic coating

may be related to the presence of condensate water. In

fully wet conditions, the effect of strip may be offset by

the presence of condensate water. But for the interrupted

fin with hydrophilic coating, the condensate water will exist on the fin surface in the form of water film, and can be

drained away easily. Therefore, the effect of strip on heat

transfer performance will appear again. The friction factors

show a crossover phenomenon as fin pitch changes like

dry surface.

Fig. 9 shows the effect of inlet relative humidity on the

airside performance with different fin pitches (Fp ¼ 1.2,

1.5, 1.7 mm for wavy and slit fin, and Fp ¼ 1.4, 1.8 mm

for louver fin). The air dry bulb temperature Ta,dry ¼ 27 C,

the inlet air flow velocity Va,in ¼ 1.0 ms1, and the corresponding number of tube rows is 2. As shown in Fig. 9,

for wavy fin, the Colburn j factors increase with the increase

of the inlet relative humidity, while the friction factors are

insensitive to the change of the inlet relative humidity. For

interrupted fin, the Colburn j factors and the friction factors

are relatively insensitive to the change of inlet relative

humidity. The cause of these results can be explained by

photographs taken in the experiments. These photographs

are shown in Fig. 10. For wavy fin, the hydrophilic coating

makes the condensate water exist on the fin surface in the

form of film. When the inlet humidity increases, the mass

flux of water film becomes bigger. The more flows of water

film enhance the airside heat transfer. But the structure of

interrupted fin is different from that of wavy fin. The strips

on the interrupted fin surface may block the flow of the water

film, so the heat transfer enhancement of water film flow is

reduced. The hydrophilic coating makes the condensate

water drain from the fin surface easily, and then there is no

water bridge to block the air flow channel, so the friction factors are independent of inlet relative humidity. Fig. 9 also

shows that airside heat transfer performance of 6 C inlet

water temperature is better than that of 12 C inlet water

temperature for wavy fin. The Coburn j factors for

RHin ¼ 80% are approximately 6e15% higher than those

at RHin ¼ 50% under 12 C inlet water temperature, and

the Coburn j factors for RHin ¼ 80% are approximately

14e32% higher than those at RHin ¼ 50% under 6 C inlet

water temperature. The possible reason is that lowering of

inlet water temperature will cause more condensate water

on the fin surface, and the heat transfer enhancement

owing to the flow of condensate water film becomes more

sensible.

5. Development of correlations

It is obvious from the previous discussions that the airside performances of the enhanced fin-and-tube heat

exchanger with hydrophilic coating are very complicated.

A multiple linear regression technique in a practical range

of experimental data (350 < ReDc < 4500) was carried out,

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1165

Fig. 11. Comparison of the proposed correlations with experimental data for wavy fin (a) j and (b) f.

and the appropriate correlation forms of j and f are given as

follows:

For wavy fin:

j ¼ 0:0605Re0:4218

Dc

f¼

j ¼ 0:2408Re0:3597

Dc

0:4122 0:8276

Fs

Pt

RH0:9222 N 0:27

Dc

Pl

ð39Þ

f ¼ 1:1285Re0:4911

Dc

Fs

Dc

0:6842 0:5947

Pt

RH0:2887 N 0:0333

Pl

ð40Þ

For interrupted fin:

0:5581

5:5335ReDc

Fs

Dc

0:7543 1:951

Pt

RH0:0073 N 0:2895

Pl

Fs

Dc

ð41Þ

0:313 0:3379

Pt

0:0045 0:1844

RH

N

Pl

ð42Þ

Ranges of applicability for Eqs. (39) and (40) are as

follows: ReDc, 350e4500; Pt, 21.0e25.4 mm; Pl,

19.05 mm; Dc, 7.21e9.74 mm; Fp, 1.2e1.8 mm; and N, 2e3.

Range of applicability for Eqs. (41) and (42) are as

follows: ReDc, 350e4500; Pt, 21.0e25.4 mm; Pl,

13.3e19.05 mm; Dc, 7.21e9.74 mm; Fp, 1.2e1.8 mm; and

N, 2e3.

Fig. 12. Comparison of the proposed correlations with experimental data for interrupted fin (a) j and (b) f.

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

1166

Table 6

Comparison of the proposed correlation with experimental dataa,b

Deviation

Wavy fin

j (%)

Interrupted fin

f (%)

j (%)

f (%)

10%

15%

20%

25%

Mean deviation

a

b

75.3

61.7

58.7

71.3

88.3

79.2

81.8

88.8

94.2

89.6

89.5

96.5

97.4

96.1

96.5

99.3

7.6

9.1

9.7

7.3

X

1

M jCorrelation Dataj

100%.

Mean deviation ¼

1

M

Data

M: number of data points.

As shown in Fig. 11, for wavy fin, the proposed heat

transfer j factor correlation, Eq. (39), can describe 88.3%

of the test data within the deviation limit of 15%, while

the correlation of the friction f factor, Eq. (40), can correlate

79.2% of the test data within the deviation limit of 15%.

The proposed correlations of j and f have a mean deviation

of 7.6% and 9.1%, respectively. As shown in Fig. 12, for interrupted fin, the proposed heat transfer j factor correlation,

Eq. (41), can describe 81.8% of the test data within the

deviation limit of 15%, while the correlation of the friction

f factor, Eq. (42), can correlate 88.8% of the test data within

the deviation limit of 15%. The proposed correlations of j

and f have a mean deviation of 9.7% and 7.3%, respectively.

Detailed comparisons between the proposed correlations of j

and f and the experimental data are depicted in Table 6.

6. Conclusion

The airside performance of enhanced fin-and-tube heat

exchanger with hydrophilic coating under wet conditions

is presented and discussed in this study. A total of 14 fin-andtube heat exchangers having enhanced fin geometry were

tested and examined. The following conclusions are made:

C

C

C

C

The wet fin efficiency analytical model for partially

wet conditions is developed. For a partially wet fin,

the fin efficiency decreases rapidly with the increase

in air inlet relative humidity. For a fully wet fin, the effect of air inlet relative humidity on the fin efficiency is

small.

The Colburn j factors decrease with the increase of the

number of tube rows. This phenomenon is especially

pronounced in the low Reynolds number region. For

wavy fin, the effect of the number of tube rows on

the friction factor is insensitive, but for interrupted

fin, the friction factors decrease slightly with the

increase of the number of tube rows.

The Colburn j factors decrease with the increase of the

fin pitch. This phenomenon becomes more pronounced

under partially wet conditions, and the friction factor is

very sensitive to change in fin pitch. The friction

C

factors also show a crossover phenomenon as fin pitch

changes like dry surface.

For wavy fin, the Colburn j factors increase with the

increase of the inlet relative humidity, while for

interrupted fin, the Colburn j factors are relatively insensitive to the change of inlet relative humidity. The

friction factors are relatively independent of inlet relative humidity. For wavy fin, the Colburn j factors of

lower inlet water temperature are bigger.

The heat transfer and friction correlations were proposed to describe the present test results. For wavy

fin, the mean deviations of the proposed j and f factor

correlations are 7.6% and 9.1%, respectively. For interrupted fin, the mean deviations of the proposed j and f

factor correlations are 9.7% and 7.3%, respectively.

Acknowledgments

The authors are very grateful to Dr C.C. Wang of ITRI,

Taiwan for giving advice and documents on experimental

rig design and correlation development for this study.

References

[1] D.R. Mirth, S. Ramadhyani, Prediction of cooling-coils performance under condensing conditions, International Journal

of Heat and Fluid Flow 14 (4) (1993) 391e400.

[2] D.R. Mirth, S. Ramadhyani, Correlations for predicting the

air-side Nusselt numbers and friction factors in chilled-water

cooling coils, Experimental Heat Transfer 7 (2) (1994)

143e162.

[3] C.C. Wang, Y.J. Du, Y.J. Chang, W.H. Tao, Airside performance of herringbone fin-and-tube heat exchangers in wet

conditions, Canadian Journal of Chemical Engineering

77 (6) (1999) 1225e1230.

[4] Y.T. Lin, Y.T. Hwang, C.C. Wang, Performance of the herringbone wavy fin under dehumidifying conditions, International

Journal of Heat Mass Transfer 45 (25) (2002) 5035e5044.

[5] W. Pirompugd, S. Wongwises, C.C. Wang, Simultaneous heat

and mass transfer characteristics for wavy fin-and-tube heat

exchangers under dehumidifying conditions, International

Journal of Heat Mass Transfer 49 (1e2) (2006) 132e143.

[6] C.C. Wang, W.S. Lee, W.J. Sheu, Y.J. Chang, Parametric

study of the air-side performance of slit fin-and-tube heat exchangers in wet conditions, Proceedings of the Institution of

Mechanical Engineers, Part C: Journal of Mechanical

Engineering Science 215 (9) (2001) 1111e1122.

[7] C.C. Wang, Y.T. Lin, C.J. Lee, Heat and momentum transfer

for compact louvered fin-and-tube heat exchangers in wet

conditions, International Journal of Heat and Mass Transfer

43 (18) (2000) 3443e3452.

[8] M.H. Kim, B. Youn, C.W. Bullard, Effect of inclination on the

air-side performance of a brazed aluminum heat exchanger

under dry and wet conditions, International Journal of Heat

and Mass Transfer 44 (24) (2001) 4613e4623.

[9] M.H. Kim, C.W. Bullard, Air-side performance of brazed

aluminum heat exchangers under dehumidifying conditions,

X. Ma et al. / International Journal of Refrigeration 30 (2007) 1153e1167

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

International Journal of Refrigeration 25 (7) (2002)

924e934.

M.H. Kim, S. Song, C.W. Bullard, Effect of inlet humidity

condition on the air-side performance of an inclined brazed

aluminum evaporator, International Journal of Refrigeration

25 (5) (2002) 611e620.

M.M. Salah EI-Din, Performance analysis of partially-wet fin

assembly, Applied Thermal Engineering 18 (1998) 337e349.

L. Rosario, M.M. Rahman, Analysis of heat transfer in a partially wet radial fin assembly during dehumidification, International Journal of Heat Fluid Flow 20 (1999) 642e648.

P. Naphon, Study on the heat transfer characteristics of the

annular fin under dry-surface, partially wet-surface, and

fully-surface conditions, International Communications in

Heat and Mass Transfer 33 (2006) 112e121.

W. Pirompugd, C.C. Wang, S. Wongwises, Finite circular fin

method for heat and mass transfer characteristics for plain

fin-and-tube heat exchangers under fully and partially wet

surface conditions, International Journal of Heat and Mass

Transfer 50 (2007) 552e565.

J.C. Min, R.L. Webb, C.H. Bemisderfer, Long-term hydraulic

performance of dehumidifying heat exchangers with and

without hydrophilic coatings, HVAC&R Research 6 (3)

(2000) 257e272.

M. Mimaki. Effectiveness of finned tube heat exchanger

coated hydrophilic-type film, ASHRAE paper #3017

presented at January meeting, 1987.

C.C. Wang, C.T. Chang, Heat and mass transfer for plate

fin-and-tube heat exchangers, with and without hydrophilic

coating, International Journal of Heat and Mass Transfer 41

(20) (1998) 3109e3120.

C.C. Wang, W.S. Lee, W.J. Sheu, Y.J. Chang, A comparison

of the airside performance of the fin-and-tube heat exchangers

in wet conditions; with and without hydrophilic coating,

Applied Thermal Engineering 22 (3) (2002) 269e278.

ASHRAE Standard 41.2-1987, Standard Methods for Laboratory Air-flow Measurement. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc, Atlanta, 1987.

R.J. Moffat, Describing the uncertainties in experimental results,

Experimental Thermal and Fluid Science 1 (1) (1988) 3e17.

1167

[21] T.H. Chilton, A.P. Colburn, Mass transfer (absorption) coefficients, Industrial and Engineering Chemistry 26 (1934)

1183e1187.

[22] ASHRAE Standard, Method of Testing Forced Circulation

Air Cooling and Air Heating Coils, American Society of

Heating, Refrigerating and Air-Conditioning Engineers, Inc.,

Atlanta, GA, 2000.

[23] F.C. McQuiston, J.D. Parker, Heating, ventilating, and air

conditioning, fourth ed. John Wiley & Sons, Inc., New

York, 1994.

[24] Th.E. Schmidt, Heating transfer calculations for extended

surfaces, Refrigerating Engineering 49 (1949) 351e357.

[25] F.C. McQuiston, Fin efficiency with combined heat and mass

transfer, ASHRAE Transactions 81 (1) (1975) 350e355.

[26] K.T. Hong, R.L. Webb, Calculation of fin efficiency for wet

and dry fins, HVAC&R Research 2 (1) (1996) 27e41.

[27] S.Y. Liang, T.N. Wong, G.K. Nathan, Comparison of onedimensional and two-dimensional models for wet surface fin

efficiency of a plate-fin-tube heat exchanger, Applied Thermal Engineering 20 (10) (2000) 941e962.

[28] W.M. Kays, A.L. London, Compact heat exchanger, third ed.

McGraw-Hill, New York, 1984.

[29] A.H. Elmahdy, R.C. Biggs, Efficiency of extended surfaces

with simultaneous heat and mass transfer, ASHRAE Transactions 89 (1) (1983) 135e143.

[30] C.C. Wang, Y.C. Hsieh, Y.T. Lin, Performance of plate finned

tube heat exchanger under dehumidifying conditions, ASME

Journal of Heat transfer 119 (1997) 109e117.

[31] C.C. Wang, Y.C. Hsieh, Y.J. Chang, Y.T. Lin, Sensible heat

and friction characteristics of plate fin-and-tube heat exchanger having plane fins, International Journal of Refrigeration 19 (4) (1996) 223e230.

[32] D.G. Rich, The effect of the number of tube rows on heat transfer performance of smooth plate fin-and-tube heat exchanger,

ASHRAE Transactions, Part 1 81 (1) (1975) 307e319.

[33] T. Yoshii, M. Yamamoto, T. Otaki, Effects of dropwise condensate on wet surface heat transfer of air cooling coils, in:

Proceedings of the 13th International Congress of Refrigeration, International Institute of Refrigeration, Paris, France,

1973, pp. 285e292.