Study on the competitiveness of the toy industry

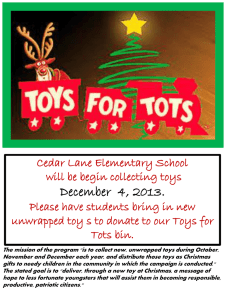

advertisement