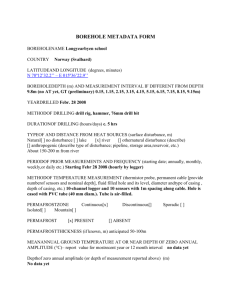

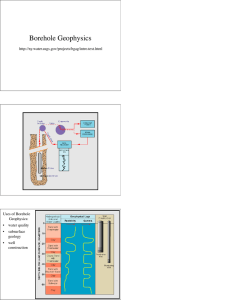

borehole drilling and rehabilitation under field conditions

advertisement