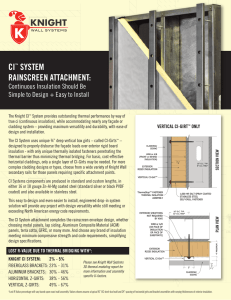

ci-system rain screen attachment

CI-SYSTEM RAIN SCREEN

ATTACHMENT: THE DEFINITION

OF FAÇADE VERSATILITY –

WITH THE EXPECTED

THERMAL PERFORMANCE.

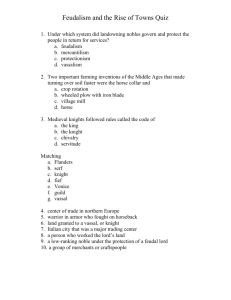

KNIGHT WALL SYSTEMS’ CI-SYSTEM RAIN SCREEN ATTACHMENT NOT

ONLY PROVIDES OUTSTANDING THERMAL PERFORMANCE BY WAY OF

TRUE CONTINUOUS INSULATION, IT WILL ALSO ACCOMMODATE NEARLY

ANY FACADE OR CLADDING SYSTEM – FOR MAXIMUM VERSATILITY, EASE

OF INSTALLATION AND A SIMPLE DESIGN.

DEVELOPED TO BE INSTALLED OVER EXTERIOR RIGID BOARD INSULATION –

WITH ONLY THERMALLY ISOLATED FASTENERS PENETRATING THE THERMAL

LAYER – KNIGHT’S CI-SYSTEM EASILY COMPLIES WITH THE NORTH AMERICAN

ENERGY CODE REQUIREMENTS FOR CONTINUOUS INSULATION (ci)*.

ADVANTAGES TO KNIGHT WALL SYSTEMS’ CI-SYSTEM RAIN SCREEN :

¤ Easily attain code compliance with exterior insulation

¤ CI-Girts can be spaced up to 32” O.C. (every other stud)

¤ High corrosive-resistant Zn-Al-Mg ZM40 coating for a long service life vs typical Galvanized steel

¤ No trimming or manipulation of exterior insulation makes installation quick and simple

¤ All fasteners penetrating the insulation are thermally isolated with preassembled washers

¤ Attach nearly any cladding with easy and efficient installation and detailing

¤ Excellent ventilation with a constant 3 /

4

-inch, or optional 1 1 /

2

-inch, continuous rain screen cavity

¤ Pre-engineered, tested and warranted

EXTERIOR INSULATION EFFECTIVENESS AS COMPARED TO ITS RATED R-VALUE WITH

+

...

...Horizontal Z-Girts: 44%-63%

...Aluminum Brackets: 54%-68%

CI-SYSTEM

: 95%-98%

* ASHRAE 90.1 prescriptive requirement for steel frame walls

+ Effective percentages vary depending upon exact wall assembly, though 24” spacing was used in determining horizontal girts & bracket assembly percentages. Contact KWS for full thermal reports.

ACCOMMODATE NEARLY ANY PANEL OR CLADDING:

Knight’s CI-System uses continuous vertical girts – called CI-Girts – that can be spaced up to 32” O.C. horizontally and support claddings that weigh up to 20 PSF*. The system uses a unique thermal isolation washer at each penetrating fastener, creating one of the most thermally efficent rain screen attachments on the market today. This drop-in system is supplied with the correct wall anchors for attaching to the stud sub-structure with

ThermaStop isolators pre-assembled on the fasteners, as well as associated rails and rail fasteners for a complete attachment solution.

CI-System may be used with or without horizontal PanelRails - cladding dependent.

*Maximum allowable spacing & dead load is a function of live loads+dead load < allowable load of wall anchor. Contact KWS for more information.

CI-SYSTEM WITH VERTICAL CI-GIRT TM ONLY :

The CI-System with only vertical CI-Girts enables the use of fiber-cement lap siding, horizontally oriented roll-formed metal siding and other horizontal siding. The system is comprised of continuous vertical members (CI-Girt) with a 2” fastening face for attaching various claddings.

CI-SYSTEM WITH VERTICAL CI-GIRT TM + HORIZONTAL PANELRAIL TM :

The CI-System with horizontal PanelRails is a must for vertically oriented siding (i.e. roll formed metal sheets, etc.), exposed fastener—or face-fastened—panels and siding systems of all kinds. It’s comprised of continuous horizontal members (featuring a 2”-5” fastening face) attaching to continuous vertical members (CI-Girt) that are attached to the substrate in a continous insulation fashion.

KNIGHT WALL CAN CONTRIBUTE TO THE

FOLLOWING USGBC LEED CREDITS:

¤ Energy & Atmosphere (EA) Prequisite and Credit 1

¤ Materials & Resources (MR) Credits 4 and 5

ALL KNIGHT WALL SYSTEMS

COMPONENTS ARE

MANUFACTURED IN THE USA.

NO EXPRESS WARRANTIES ARE GIVEN EXCEPT FOR ANY APPLICABLE WRITTEN WARRANTIES

SPECIFICALLY PROVIDED BY KNIGHT WALL SYSTEMS. ALL IMPLIED WARRANTIES INCLUDING

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

EXCLUDED. No freedom from any patent owned by Knight Wall Systems or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use.

KNIGHT

WALL SYSTEMS

28308 N Cedar Road, Deer Park, WA 99006 www.knightwallsystems.com

1-855-597-9255 (KWS-WALL)

509.262.0104

MFI-System, ThermaBracket, ThermaStop and PanelRail are trademarks of Knight Wall Systems. Patent US 8,429,866 B2 and others pending