Inorganic LCD Technology

Technology Guide

Introduction

Liquid-crystal display (LCD) technology has come a long way from

its humble beginnings back in the early 1970’s when it first appeared

in calculators and digital watches. Today, it has blossomed into the

dominant technology for all manner of displays, from mobile phones

and digital cameras to desktop monitors and high-definition televisions.

In a variant known as high-temperature poly-silicon (HTPS) LCD is also

the most popular technology for digital projectors. Projection is a more

challenging application for a liquid-crystal device than a direct-view

display. In order to project a bright image most digital projectors use

a short-arc, high-intensity discharge lamp based on Mercury vapor

or Xenon as their internal light source. Historically, achieving the right

balance between high brightness and high contrast with these lamps

has been tricky.

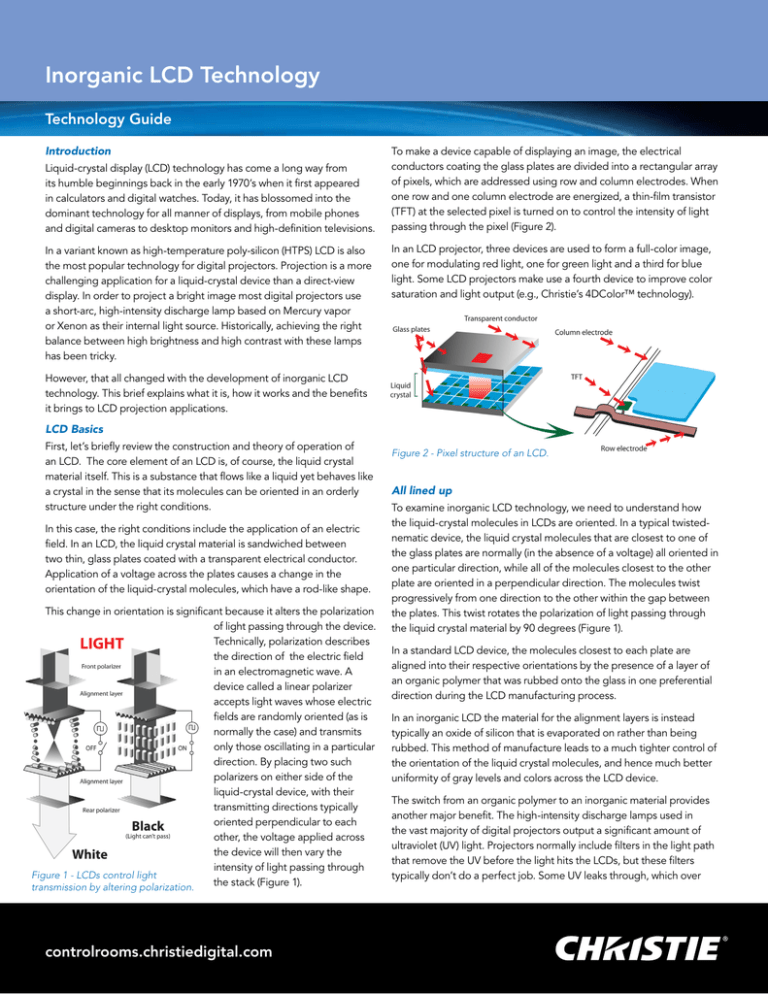

To make a device capable of displaying an image, the electrical

conductors coating the glass plates are divided into a rectangular array

of pixels, which are addressed using row and column electrodes. When

one row and one column electrode are energized, a thin-film transistor

(TFT) at the selected pixel is turned on to control the intensity of light

passing through the pixel (Figure 2).

In an LCD projector, three devices are used to form a full-color image,

one for modulating red light, one for green light and a third for blue

light. Some LCD projectors make use a fourth device to improve color

saturation and light output (e.g., Christie’s 4DColor™ technology).

However, that all changed with the development of inorganic LCD

technology. This brief explains what it is, how it works and the benefits

it brings to LCD projection applications.

LCD Basics

First, let’s briefly review the construction and theory of operation of

an LCD. The core element of an LCD is, of course, the liquid crystal

material itself. This is a substance that flows like a liquid yet behaves like

a crystal in the sense that its molecules can be oriented in an orderly

structure under the right conditions.

In this case, the right conditions include the application of an electric

field. In an LCD, the liquid crystal material is sandwiched between

two thin, glass plates coated with a transparent electrical conductor.

Application of a voltage across the plates causes a change in the

orientation of the liquid-crystal molecules, which have a rod-like shape.

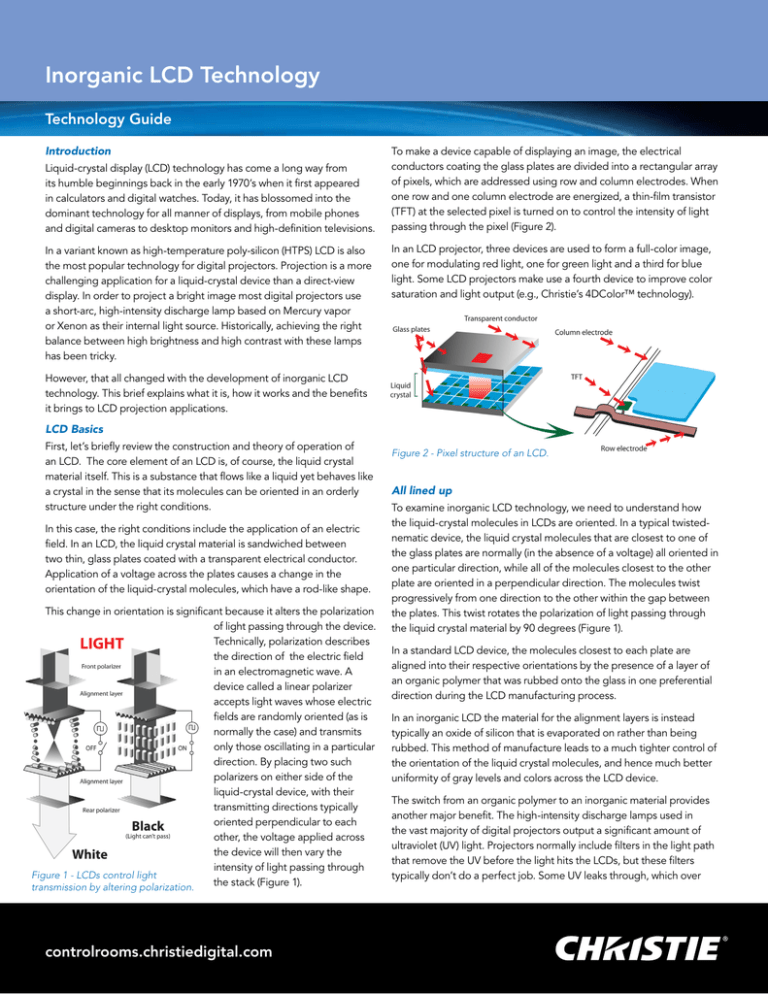

This change in orientation is significant because it alters the polarization

of light passing through the device.

Technically, polarization describes

the direction of the electric field

in an electromagnetic wave. A

device called a linear polarizer

accepts light waves whose electric

fields are randomly oriented (as is

normally the case) and transmits

only those oscillating in a particular

direction. By placing two such

polarizers on either side of the

liquid-crystal device, with their

transmitting directions typically

oriented perpendicular to each

other, the voltage applied across

the device will then vary the

intensity of light passing through

Figure 1 - LCDs control light

the

stack (Figure 1).

transmission by altering polarization.

controlrooms.christiedigital.com

Figure 2 - Pixel structure of an LCD.

All lined up

To examine inorganic LCD technology, we need to understand how

the liquid-crystal molecules in LCDs are oriented. In a typical twistednematic device, the liquid crystal molecules that are closest to one of

the glass plates are normally (in the absence of a voltage) all oriented in

one particular direction, while all of the molecules closest to the other

plate are oriented in a perpendicular direction. The molecules twist

progressively from one direction to the other within the gap between

the plates. This twist rotates the polarization of light passing through

the liquid crystal material by 90 degrees (Figure 1).

In a standard LCD device, the molecules closest to each plate are

aligned into their respective orientations by the presence of a layer of

an organic polymer that was rubbed onto the glass in one preferential

direction during the LCD manufacturing process.

In an inorganic LCD the material for the alignment layers is instead

typically an oxide of silicon that is evaporated on rather than being

rubbed. This method of manufacture leads to a much tighter control of

the orientation of the liquid crystal molecules, and hence much better

uniformity of gray levels and colors across the LCD device.

The switch from an organic polymer to an inorganic material provides

another major benefit. The high-intensity discharge lamps used in

the vast majority of digital projectors output a significant amount of

ultraviolet (UV) light. Projectors normally include filters in the light path

that remove the UV before the light hits the LCDs, but these filters

typically don’t do a perfect job. Some UV leaks through, which over

Inorganic LCD Technology

Technology Guide

time can literally “cook” the organic molecules of a polymer alignment

layer, breaking down their molecular cohesion.

An inorganic alignment layer does not absorb as much UV and hence

is significantly more resistant to UV-induced damage. This translates

directly into a much higher device reliability and the ability to withstand

much higher levels of light.

Standing Tall

A pixel of a typical twisted-nematic LCD device normally appears white

when no voltage is applied across the glass plates. In the presence

of a voltage the liquid crystal molecules start to “untwist,” rotating

the polarization by less than 90 degrees, which results in less light

transmitted through the pixel. At some voltage the molecules align in a

vertical direction and the pixel blocks as much light as it can, producing

as deep a black as possible. (Figure 3).

Figure 4 - The vertically aligned liquid crystal of an inorganic panels is

normally black.

the use of inorganic alignment layers with their extremely uniform

characteristics ensures that the molecules are all accurately aligned in

the vertical direction with little variation, which reduces scattering and

the resultant light leakage to a minimum.

The Benefits

Inorganic alignment technology and the “vertically aligned” (normally

black) mode of operation that comes with it provide powerful benefits

to LCD projection applications.

Figure 3 - A standard twisted nematic LCD normally displays white.

Unfortunately, because of natural variations not all molecules align

precisely vertical. This increases scattering, which lets some light leak

through. Because of this effect, the black levels traditionally achieved

by LCDs have not been as dark as those achieved by other projection

technologies such as LCoS (Liquid Crystal on Silicon) and DLP®.

However, the use of inorganic alignment layers allows an entirely

different mode of operation. In this mode, the rod-like liquid crystal

molecules are all aligned vertically in the absence of a voltage. This

makes the display normally black instead of normally white. Application

of a voltage then starts to twist the molecules, allowing more light

through as the voltage increases (Figure 4).

The most visible benefit is a vastly improved contrast ratio, due to the

achievement of a far deeper black than would otherwise be possible.

This improves the readability of fine text and graphics and adds

“punch” to video material, especially in darker scenes. Less obviously, it

makes colors far more vibrant, particularly darker tones closer to black.

Another immediately visible benefit is the increase in light output that

inorganic alignment layers allow by virtue of their greatly improved

resistance to damage from UV light. More light means brighter images

that withstand higher levels of ambient illumination, making projection a

viable display option in a wider variety of environments.

Improved resistance to UV light also results in higher reliability.

Practically speaking, it means you no longer have to worry about the

number of cumulative hours that an LCD projector has been operating.

In short, inorganic LCD technology enables brighter images, deeper

blacks and higher reliability – a winning combination.

The normally black mode allows a far deeper black to be produced.

Not only does the black state not depend on an analog voltage, but

Independent sales

consultant offices

Corporate offices

Worldwide offices

Christie Digital Systems USA, Inc

USA – Cypress

ph: 714 236 8610

United Kingdom

ph: +44 (0) 118 977 8000

United Arab Emirates

ph: +971 (0) 4 299 7575

China (Beijing)

ph: +86 10 6561 0240

Spain

ph: +34 91 633 9990

Germany

ph: +49 2161 664540

India

ph: (080) 41468941 – 48

Japan (Tokyo)

ph: 81 3 3599 7481

Italy

ph: +39 (0) 2 9902 1161

France

ph: +33 (0) 1 41 21 44 04

Singapore

ph: +65 6877 8737

Korea (Seoul)

ph: +82 2 702 1601

South Africa

ph: +27 (0) 317 671 347

Eastern Europe and

Russian Federation

ph: +36 (0) 1 47 48 100

China (Shanghai)

ph: +86 21 6278 7708

Christie Digital Systems Canada, Inc.

Canada – Kitchener

ph: 519 744 8005

For the most current specification information, please visit http://www.christiedigital.com

Copyright 2010 Christie Digital Systems USA, Inc. All rights reserved. All brand names and product names are trademarks, registered trademarks

or tradenames of their respective holders. Canadian manufacturing facility is ISO 9001 and 14001 certified. Performance specifications are typical.

Due to constant research, specifications are subject to change without notice. Inorganic Technical Guide April 10