technical data - Induron Protective Coatings

advertisement

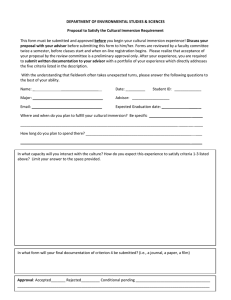

HNI RUFF STUFF 3300 800 324 9584 | 3333 R. ARRINGTON N. BHAM, AL 35234 Certified to COATING DATA DESCRIPTION: A two-component, high solids, chemically cured epoxy coating. Ruff Stuff 3300 is a unique and outstanding barrier coating for the protection of steel, iron, or concrete exposed to potable water or aggressive chemical environments. Ruff Stuff 3300 has an extensive history of proven successful use in lining steel, ductile iron, concrete tanks and pipe subjected to potable water or other aggressive chemical agents. Ruff Stuff 3300 meets the requirements of American Water Works Association Standard C-210 and the requirements of ANSI/AWWA D102-03 ICS-1. Approved under ANSI/NSF International Standard 61 for potable water immersion service in tanks of 1000 gallons and greater capacity and potable water pipe 20 inches and greater. USE: A protective barrier coating for tanks, pipe, and structural elements exposed to potable water or aggressive chemical agents. It also is ideal for protecting steel and concrete immersed in fresh, sea, and chemically contaminated water. The very high film build capabilities of Ruff Stuff 3300 makes it ideal for use over pitted steel or in very corrosive environments as a primer, intermediate or finish coat. TEST METHOD/CONDITIONS DURATION RESULTS SALT SPRAY ASTM B 117 (Unscribed) 1,000 Hours EXTERIOR EXPOSURE WATER IMMERSION CATHODIC DISBONDMENT 45° South, Birmingham, AL 160°F (71°C) 77 °F (25°C) ASTM G 8-85 Method A 3 Years, 8 Months 500 Hours 720 Hours 16 Gauge Panel 25% SODIUM HYDROXIDE 3% SULFURIC ACID 5% SODIUM BISULFITE ADHESION DIRECT IMPACT EXTRACTABLES 140°F (60°C) 120°F (50C) 77°F (25C) ASTM D 2794 Immersion U.S. FDA 8,760 Hours 720 Hours 720 Hours 1,000 psi No Blisters or Undercutting No Erosion No Effect No Effect <1% Disbondment No Effect No Effect No Effect No Effect 120 in./lb. 0.05 mg./cm.2 DISTILLED WATER IMMERSION LIMITATIONS: Do not use for immersion service above 120°F (49°C) or dry heat above 200°F (93°C). Not recommended for immersion in concentrated solutions of mineral acids or organic acids. SURFACE PREPARATION: Steel (Immersion)—SSPC-SP 10 Near White Blast. Steel (Non-Immersion)—SSPC-SP 6 Commercial Blast. Ductile Iron—Remove all surface contaminants by abrasive blasting. Do not coat surfaces previously coated with asphalt. Concrete—SSPC-SP 7 Brush Off Blast. New concrete must cure at least 28 days and contain less than 14% moisture prior to painting. Recoating—Multicoat systems require this product to be recoated. This product does not require scarifying the surface prior to being recoated with any product listed under recommended PRIMERS/TOPCOATS. Prior to recoating, remove all chalk and/or other surface contaminants. 0908 PRIMERS/TOPCOATS: NSF/ANSI Standard 61 certified potable water immersion primers: Ruff Stuff 3300, PE-54 Epoxy, PE-54 RC Epoxy. NSF/ANSI Standard 61 potable water immersion topcoats: Ruff Stuff 3300 Epoxy, PE-54 Epoxy, PE-54 RC Epoxy. Non-Potable water applications: Perma-Clean II Epoxy, Armorguard Epoxy, Indurethane 5500 Enamel. COVERAGE: Theoretical—962 ft2 per gallon at 1.0 mil dry film thickness. DRY FILM THICKNESS: 6.0 to 9.0 mils per coat. WET FILM THICKNESS: 10.0 to 15.0 mils. APPLICATION DATA BLEND RATIO: One part Ruff Stuff 3300 Activator to 9 parts Ruff Stuff 3300 Base by volume. Power agitate until components are thoroughly mixed. Allow mixed components to stand fifteen minutes prior to application. POT LIFE: Eight hours at 80°F decreasing with higher temperature. APPLICATION: Airless Spray—Use .029 tip; 30 mesh filter; 30:1 Pump ratio at 80-100 psi operating air pressure. Roll— Use lambswool cover. Additional coats may be required to achieve desired film thickness. Brush—Use natural bristle brush. Additional coats may be required to achieve desired film thickness. THINNING: If required, thin up to 10% with K-1066 Reducer. Clean equipment with K-1066 Reducer. CLIMATE: Use this product only if the substrate temperature and ambient air temperature is above 40°F and is expected not to decrease for at least two hours after application. Also, the substrate temperature must be 5°F above the dewpoint for a period of at least two hours after application to avoid condensation occurring on wet paint. DRY TIME: TO HANDLE—9 hours at 80°F. TO RECOAT—50°F or higher, overnight; 40°F-50°F, second day. IMMERSION SERVICE—50°F or higher, seven days with proper ventilation; 40°F-50°F, 14 days with proper ventilation. Ventilation during application and after must be in accordance with AWWA D102-03 Section 4.6.5. Due to varying tank designs, interior circulation may be necessary to avoid dead air spaces. Note: High film thickness, low temperature and/or poor ventilation will retard dry time. PHYSICAL DATA: VOLUME SOLIDS: 60% ± 1% SOLIDS BY WEIGHT: 71% ± 1% WEIGHT PER GALLON: 10.87 ± .2 lbs per gallon (mixed) VOLATILE ORGANIC CONTENTS: < 2.8 lbs/gallon mixed unthinned; < 350 grams/liter SAFETY DATA: See individual product label for safety and health data information. Individual Material Safety Data Sheets are available upon request. 0908