16450-1 11/13 SECTION 16450 DRY

advertisement

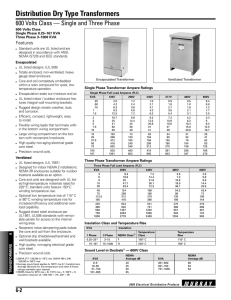

SECTION 16450 DRY-TYPE TRANSFORMERS PART 1 - GENERAL 1.01 REQUIREMENTS A. 1.02 SCOPE A. 1.03 The general provisions of the Contract, including General and Supplementary Conditions and General Requirements, apply to the work specified in this Section. The work under this Section shall include furnishing and installing TP-1 dry-type energy efficient transformers complete as shown on the Drawings and herein specified. Provide all lugs, accessories and mounting hardware necessary for proper installation and operation. QUALITY ASSURANCE A. All equipment, materials and their installation shall conform to the requirements of the National Electrical Code (NEC), local code requirements, and these Specifications. B. Transformers shall meet the requirements of Federal Law 10 CFR Part 431 “Energy Efficiency Program for Certain Commercial and Industrial Equipment” and bear the Energy Star® label. C. The transformer manufacturer shall be ISO 9001 or 9002 certified. D. All equipment and material shall be listed by Underwriter's Laboratories, Inc. (UL) for their intended use and shall bear the UL label. E. Equipment shall be constructed and tested in accordance with National Electrical Manufacturer's Association (NEMA) standards including TP-1, TP-2 and TP-3. F. Submittals are required in accordance with SECTION 16010 of these Specifications. The following minimum information shall be submitted: 1. Outline dimensions and weights. 2. Technical certification sheet. 3. Transformer ratings including: a. b. c. kVA Primary and secondary voltage. Taps. 16450-1 11/13 DRY-TYPE TRANSFORMERS d. e. f. 4. 1.04 SECTION 16450 Design impedance. Insulation class and temperature rise. Sound level. Product data sheets. DELIVERY, STORAGE AND HANDLING A. Handle transformers in accordance with manufacturer’s recommendations. Utilize factory provisions for all lifting, rigging, or hoisting. B. Store transformers prior to installation in a temperature and humidity controlled space. If such a space is not available, apply temporary heat in accordance with the manufacturer’s instructions within each ventilated type transformer case to exclude moisture and condensation. PART 2 - PRODUCTS 2.01 MATERIALS AND COMPONENTS A. Dry-type energy efficient transformers shall be indoor, dry, ventilated, quiet type and shall be constructed and tested in accordance with the latest applicable standards of ANSI, NEMA and UL. B. Ratings: 1. KVA and voltage ratings shall be as shown on the drawings. 2. Transformers shall be designed for continuous operation at rated kVA, for 24 hours a day, 365 days a year operation, with normal life expectancy as defined in ANSI C57.96. 3. Transformer sound levels shall not exceed the following ANSI and NEMA levels for self-cooled ratings: 0 10 51 151 301 4. to to to to to 9 kVA 50 kVA 150 kVA 300 kVA 500 kVA 40 dB 45 dB 50 dB 55 dB 60 dB Transformers shall be low loss type with minimum efficiencies as listed in NEMA TP-1 when operated at 35% of full load capacity. Efficiency shall be tested in accordance with NEMA TP-2. 16450-2 11/13 DRY-TYPE TRANSFORMERS C. D. SECTION 16450 Insulation Systems: 1. Transformer insulation system shall be 220 degrees C insulation system with 150 degree C rise, ventilated design. 2. Required performance shall be obtained without exceeding the above indicated temperature rise in a 40 degrees C maximum ambient, and a 24 hour average ambient of 30 degrees C. 3. All insulation materials shall be flame-retardant and shall not support combustion as defined in ASTM Standard Test Method D635. Core and Coil Assemblies: 1. Transformer core shall be constructed with high-grade, nonaging, silicon steel with high magnetic permeability, and low hysteresis and eddy current losses. Maximum magnetic flux densities shall be substantially below the saturation point. The transformer core volume shall allow efficient transformer operation at 10% above the nominal tap voltage. The core laminations shall be tightly clamped and compressed. Coils shall be wound of high quality electrical grade aluminum with continuous wound construction. 2. On three-phase units rated 15 kVA and above the core and coil assembly shall be impregnated with non-hydroscopic, thermosetting varnish and cured to reduce hot spots and provide a flame retardant seal and seal out moisture. The assembly shall be installed on vibration-absorbing pads. There shall not be any metal-to-metal contact between the core and coil assembly and the enclosure except for a flexible safety ground strap. E. Three-phase transformers rated 15 through 500 kVA shall be provided with six 21/2% taps, two above and four below rated primary voltage. F. Enclosure: 1. The enclosure shall be made of heavy-gauge steel. All transformers shall be equipped with a wiring compartment suitable for conduit entry and large enough to allow convenient wiring. The maximum temperature of the enclosure shall not exceed 90 degrees C. The core of the transformer shall be visibly grounded to the enclosure by means of a flexible grounding conductor sized in accordance with applicable UL and NEC standards. 2. On three-phase transformers rated 15 kVA and above the enclosure construction shall be ventilated, NEMA 2, drip-proof, with lifting holes. All 16450-3 11/13 DRY-TYPE TRANSFORMERS SECTION 16450 ventilation openings shall be protected against falling dirt. Enclosures shall be finished with ANSI gray color, weather-resistant enamel. 3. G. 2.02 On ventilated outdoor units provide suitable weathershields over ventilation opening, conforming to the requirements of NEMA 250, Type 3R. Suitable screens shall be provided to prevent insertion of foreign debris and animals in the ventilation openings. Dry-type transformers shall be as manufactured by EATON/CUTLER-HAMMER, GENERAL ELECTRIC, SIEMENS, or SORGEL (SQUARE D). NAMEPLATE A. Transformers shall have nameplates of 1/16 inch thick laminated plastic with 3/16 inch high white letters on a black background. Nameplates shall identify the transformer and shall be mounted on the top front edge of the enclosure. Nameplates shall be screw fastened using stainless steel screws. Nameplates for transformers on emergency power shall have a red background. PART 3 – EXECUTION 3.01 FACTORY TESTING A. 3.02 The following standard factory tests shall be performed on the equipment provided under this section. All tests shall be in accordance with latest version of ANSI and NEMA standards. 1. Ratio tests at the rated voltage connection and at all tap connections. 2. Polarity and phase relation tests on the rated voltage connection. 3. Applied voltage tests. 4. Induced potential test. 5. No-load and excitation current at rated voltage on the rated voltage connection. INSTALLATION A. Transformers, shown on the Drawings to be floor mounted shall have a four (4) inch high by four (4) inch greater all sides concrete base. Connections shall be made with flexible metal conduit. 16450-4 11/13 DRY-TYPE TRANSFORMERS 3.03 3.04 SECTION 16450 B. Transformer manufacturer's nameplates, marked in accordance with NEMA Specifications, shall be permanently attached to the transformer in a readily accessible position. C. Transformer secondary neutral shall be grounded as per NEC requirements, and/or hereinafter specified. D. This Contractor shall install the transformer to insure that the minimum clearances required by the transformer manufacturer are provided. These clearances shall be clearly labeled on the transformer by the manufacturer. E. Install units plumb, level and rigid without distortion. ADJUSTMENTS AND CLEANING A. On completion of installation, inspect components. Remove paint splatters and other spots, dirt and debris. Repair scratches and mars on finish to match original finish. Clean components internally using methods and materials recommended by the manufacturer. B. Adjust transformer taps to provide optimum voltage conditions at utilization equipment throughout normal operating cycle of the facility. Measure and record primary and secondary voltages and tap settings and submit with test results. FIELD TESTING A. Include the following minimum inspections and tests according to manufacturer’s written instructions. Comply with IEEE C57.12.91 for test methods and data correction factors. B. Inspect accessible components for cleanliness, mechanical and electrical integrity and damage or deterioration. Verify that temporary shipping bracing has been removed. Include internal inspection through access panels and covers. C. Inspect bolted electrical connections for tightness according to manufacturer’s published torque values or, if not available, those specified in UL 486A and UL 468B. END OF SECTION 16450-5 11/13